Photo-cured silicon carbide ceramic slurry as well as preparation method and application thereof

A technology of silicon carbide ceramics and light curing, applied in the field of 3D printing ceramics, can solve the problems of large difference in refractive index between silicon carbide powder and photosensitive resin, high solid phase content of silicon carbide ceramics, high absorption rate of silicon carbide powder, etc. , to achieve the effect of improving light curing ability, excellent mechanical properties and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

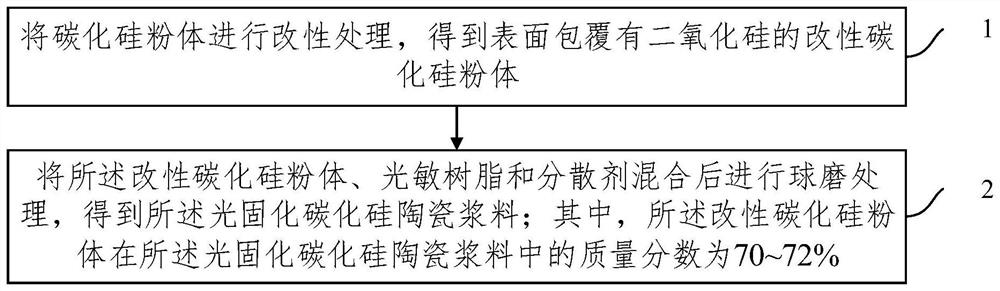

[0038] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a light-cured silicon carbide ceramic slurry, the preparation method comprising the following steps:

[0039] (1) modifying the silicon carbide powder to obtain a modified silicon carbide powder whose surface is coated with silicon dioxide;

[0040] (2) The modified silicon carbide powder, photosensitive resin and dispersant are mixed and then ball milled to obtain the photocured silicon carbide ceramic slurry; wherein, the modified silicon carbide powder is prepared in the photocured The mass fraction in the silicon carbide ceramic slurry is 70-72% (for example, it may be 70%, 70.5%, 71%, 71.5% or 72%).

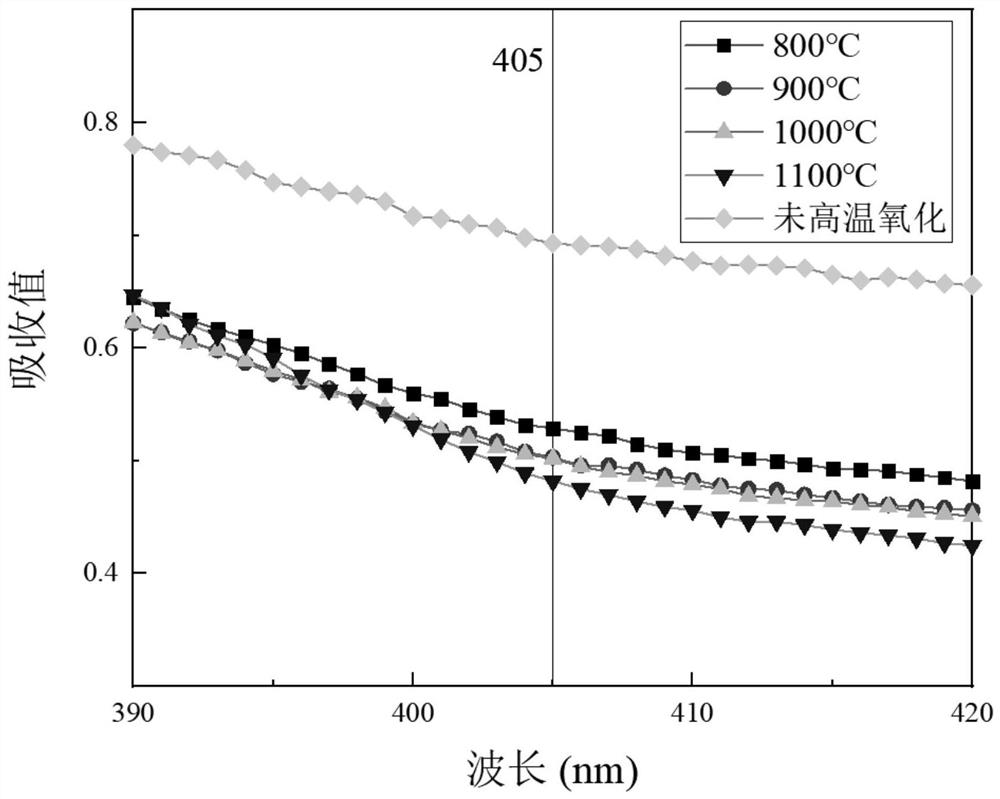

[0041] In the present invention, by modifying the silicon carbide powder, the surface of the modified silicon carbide powder is coated with a small amount of SiO 2 , and then reduce its ultraviolet absorption, so that more ultraviolet light can be irradiated on the pho...

Embodiment 1

[0085] Preparation of light-cured silicon carbide ceramic slurry:

[0086] (1) Put silicon carbide powder (10 μm in particle size) in a high-temperature sintering furnace and raise the temperature to 900°C at a heating rate of 5°C / min. After holding for 0.5h, it is directly cooled with the furnace to obtain a surface coated with silicon dioxide. Modified silicon carbide powder;

[0087] (2) Select ditrimethylolpropane acrylate as the prepolymer, 1,6-hexanediol diacrylate as the diluent, and mix the prepolymer and the diluent uniformly at a mass ratio of 1:1, Then add the photoinitiator TPO (being (2,4,6-trimethylbenzoyl) diphenyl phosphorus oxide) of 2wt% (relative to the total mass of prepolymer and diluent), mix by magnetic stirrer Uniformly, the photosensitive resin is prepared;

[0088] Put 35g of modified silicon carbide powder obtained in step (1), 13.95g of photosensitive resin and 1.05g of dispersant BYK-103 in a ball mill jar, and at a speed of 150rpm, first rotate ...

Embodiment 2

[0093] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0094] In the preparation process of light-cured silicon carbide ceramic slurry, the dispersant is KOS110, specifically:

[0095] In step (2), 35g of modified silicon carbide powder obtained in step (1), 13.25g of photosensitive resin and 1.75g of dispersant KOS110 were placed in a ball mill jar and rotated forward for 30min at a speed of 150rpm, Stay for 4 minutes, then reverse rotation for 30 minutes, and stay for 4 minutes. After a total of 3 hours of ball milling, the light-cured silicon carbide ceramic slurry (viscosity is 1052.31mPa·s) is obtained;

[0096] Wherein, the mass fraction of the modified silicon carbide powder in the light-cured silicon carbide ceramic slurry is 70%; the mass of the dispersant is 5 wt% of the mass of the modified silicon carbide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com