Gasoline additive capable of remarkably reducing precipitate in gasoline engine combustion chamber

A gasoline engine and gasoline additive technology, applied in the direction of fuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of engine compression ratio increase, engine fuel consumption increase, emission deterioration, etc., and achieve the effect of reducing the amount of increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

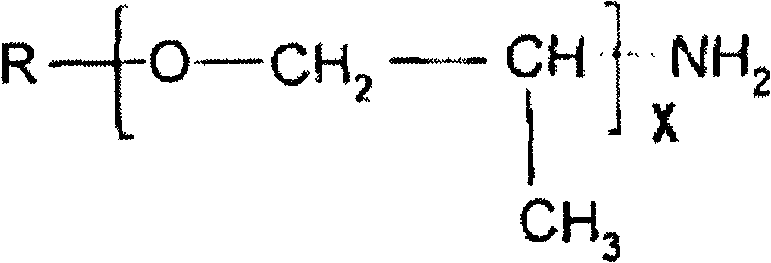

[0025] The high surface active polyisobutylene amine used is Keropur PIBA from BASF Company in Germany, the high surface active polyether amine used is SURFONAMINE FLK-1000 from HUNTSMAN Company in the United States, the wear reducer used is H6457 from Afton Company, and the oil used is The soluble polyether carrier liquid is a copolymer of propylene oxide with a C / 0 above 3.5 and a weight-average molecular weight of 800-1200. Cosolvents, antioxidants, rust inhibitors, preservatives, and demulsifiers are all typical commercially available product.

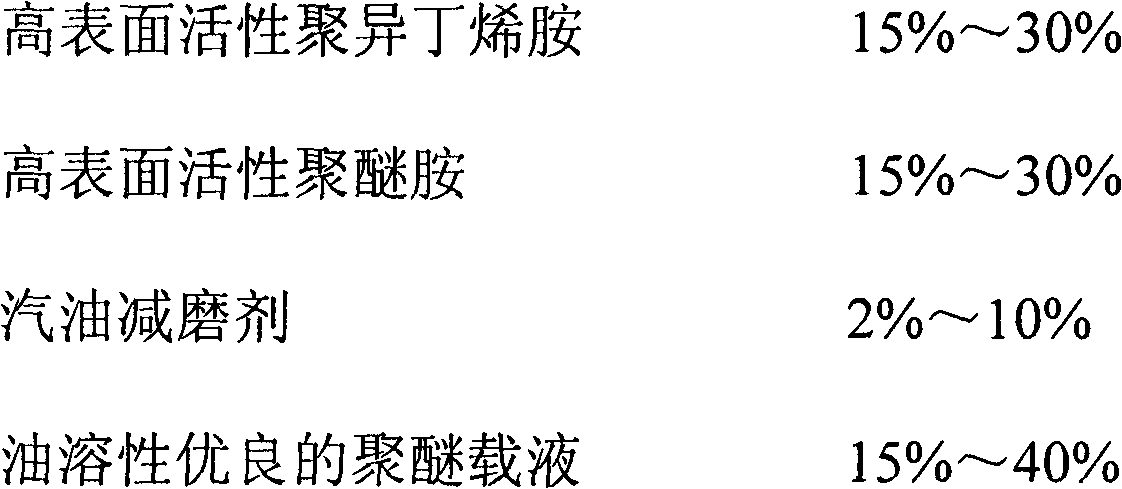

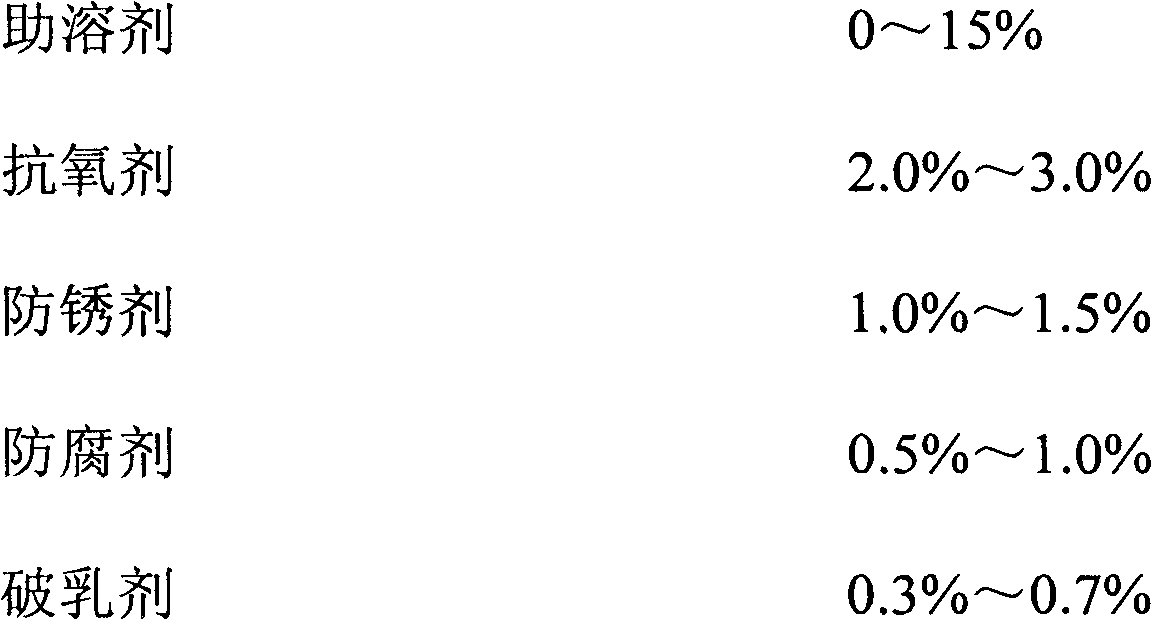

[0026] The mass percent of each component is:

[0027]

[0028]

[0029] Weigh the above required components in proportion, mix them at room temperature or not higher than 60°C, and stir evenly until transparent to obtain the gasoline detergent of the present invention. Add this additive to the market at a dosage of 350-440ppm 93 # In gasoline, the physical and chemical analysis data of the oil products all meet the require...

Embodiment 2

[0031] Use the high surface activity polyisobutylene amine, polyether amine and gasoline antifriction agent of embodiment 1, repeat the preparation method of embodiment 1, prepare the mass percent of each component of gasoline detergent of the present invention as follows:

[0032]

[0033] Add this additive to commercially available 93 by 380-450ppm # In gasoline, the physical and chemical analysis data of the oil products all meet the requirements of GB17930-2006 after inspection by the professional inspection department. The reduction rate of simulated intake valve deposits is 98%. Using high-temperature (above 500°C) thermogravimetric analysis to simulate the incremental change of combustion chamber deposits, it is 92.8% lower than the current commercially available gasoline additives.

Embodiment 3

[0035] Use the high surface activity polyisobutylene amine, polyether amine and gasoline antifriction agent of embodiment 1, repeat the preparation method of embodiment 1, prepare the mass percent of each component of gasoline detergent of the present invention as follows:

[0036]

[0037] Add this additive to commercially available 93 by dosage of 60-500ppm # In gasoline, the physical and chemical analysis data of the oil products all meet the requirements of GB17930-2006 after inspection by the professional inspection department. The reduction rate of simulated intake valve deposits is 96%. Using high-temperature (above 500°C) thermogravimetric analysis to simulate the incremental change of combustion chamber deposits, it is 91.8% lower than the current commercially available gasoline additives.

[0038] In summary, the formulations of 3 embodiments of the present invention are added to the currently commercially available motor gasoline at 220-550ppm by dosage, which ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com