Composite coating material for metal surface and application thereof

A composite coating and metal surface technology, which is applied in the direction of surface coating liquid devices, coatings, conductive coatings, etc., can solve the problems of increasing the cost of connecting parts and process complexity, and achieve reduced production costs and low sintering temperatures , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

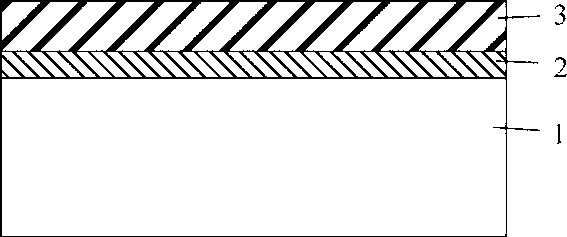

[0022] figure 2 It is a schematic diagram of an embodiment of using the composite coating material of the present invention to form a protective coating on the surface of a metal part.

[0023] In this embodiment, Inconel625 plate is used as the coated substrate 1 . The metal substrate is mechanically polished step by step from 40# to 800# sandpaper. Substrates were cleaned ultrasonically in absolute ethanol before applying the coating. Before coating, the substrate is pre-oxidized at 900°C / 2h in air.

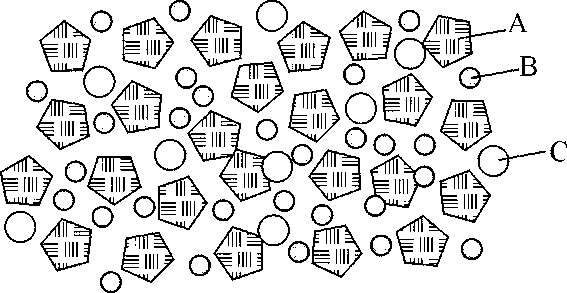

[0024] In this embodiment, the conductive composite oxide contained in the coating 3 is prepared by the sol-gel method, and the composition is La0.7Sr 0.3 CoO 3 The powder has an average particle size of about 0.5 μm. La 0.7 Sr 0.3 CoO 3 Powder, MnO 2 Co powder and Co powder are mixed in a molar ratio of 65:30:5, n-butanol and PVB are added as organic solvents and binders, the weights of which are 80% and 5% of the total weight of the solid phase powder, and the solid p...

Embodiment 2

[0027] In this embodiment, a SUS430 plate is used as the coated substrate 1 . The metal substrate was mechanically polished step by step from 40# to 800# sandpaper, and ultrasonically cleaned in absolute ethanol. Before coating, the substrate is pre-oxidized at 800°C / 24h.

[0028] In this embodiment, the conductive composite oxide contained in the coating 3 is prepared by a solid state reaction method and the composition is MnFe 2 o 4 The powder has an average particle size of about 1.3 μm. MnFe 2 o 4 Powder, Co 3 o 4 Fe powder and Fe powder are mixed at a molar ratio of 50:40:10, ethanol and PVA are added as organic solvents and binders, and their weights are 120% and 6% of the total weight of the solid phase powder, and the solid phase content is formed after ultrasonic dispersion. The slurry is 44%, and the slurry is evenly coated on the surface of the alloy substrate by dip coating. After drying, it is sintered at 800° C. for 12 hours. The thickness of the coating 3...

Embodiment 3

[0031] In this embodiment, a SUS430 plate is used as the coated substrate 1 . The metal substrate was mechanically polished step by step from 40# to 800# sandpaper, and ultrasonically cleaned in absolute ethanol.

[0032] In this embodiment, the conductive composite oxide contained in the coating 3 is prepared by a solid-state reaction method and the composition is Cu 1.3 co 1.7 o 4 powder, the average particle size of the powder is about 1.6 μm. Will Cu 1.3 co 1.7 o 4 Powder, MnO 2 The powder is mixed in a molar ratio of 80:20, and n-butanol and PVB are added as an organic solvent and a binding agent, and its weight is respectively 200% and 10% of the total weight of the solid phase powder, and after ball milling and dispersing, a solid phase content of 32% is formed. The slurry is uniformly coated on the surface of the alloy substrate by dip coating, and then sintered at 800° C. for 24 hours after drying. The thickness of the coating 3 is about 5-7 μm.

[0033] The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com