Method for preparing graphene foam material from furfural acetone formaldehyde resin, graphene foam material and application of graphene foam material

A technology composed of furfural aldehyde resin and graphene foam, which is applied in the field of material preparation, can solve the problems of low carbon content of phenolic resin carbon foam materials, difficult and uneven foaming rate, non-renewable fossil energy, etc., to achieve High thermal stability, low thermal expansion coefficient, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment relates to a graphene foam material and its preparation method and application.

[0026] The method for preparing graphene foam material by furfural aldehyde resin, comprises the following steps:

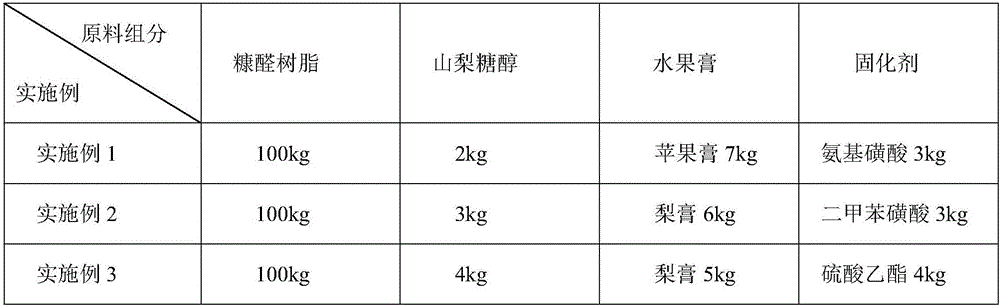

[0027] a. Take furfural aldehyde resin, add sorbitol and sugar-containing fruit paste, heat to 30-40°C, stir for 20 minutes, then add curing agent, continue to heat up to 45-55°C at a rate of 1-2°C for 1 minute ℃, stirring for 10 minutes to obtain a furfural aldehyde mixture; the fruit paste can be boiled from sugar-containing fruit and water to obtain a fruit paste with a solid content of 65-75%;

[0028] b. Put the mixed furfural aldehyde mixture into the mold, raise the temperature to 60-100°C at a heating rate of 1-2°C for 3 minutes, keep it warm for 50 minutes, and then raise the temperature to 100-100°C at a heating rate of 1-2°C for 2 minutes 130°C, keep warm for 1 hour, and perform curing and molding;

[0029]c. Put the fully cured furfural aldehyde ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com