Brazing filler metal for SiC base composite material connection

A technology of composite materials and brazing filler metals, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] The present embodiment is the preparation of powdered solder, comprising the following steps:

[0039] (1) According to the composition 4wt% ~ 18wt% Ti or TiH 2 , 2wt% to 10wt% Al, and the rest is Cu. The powders of the three components are weighed, and the purity is higher than 99.0%;

[0040] (2) Put the weighed powder into a container filled with acetone for ultrasonic treatment to make the powder evenly mixed, and then dry at 60° C. to 80° C. to obtain solder powder.

Embodiment approach 2

[0042] The present embodiment is the preparation of powdered solder, comprising the following steps:

[0043] (1) According to the composition 4wt% ~ 18wt% Ti or TiH 2 , 2wt% to 10wt% Al, and the rest is Cu. The powders of the three components are weighed, and the purity is higher than 99.0%;

[0044] (2) Put the powder directly into an agate mortar and grind thoroughly, and mix evenly to obtain brazing material powder.

Embodiment approach 3

[0046] This embodiment is the preparation of paste solder, comprising the following steps:

[0047] (1) dissolving polyvinyl butyral (PVB) in cyclohexanone, so that the concentration is 1wt% to 8wt%, to obtain a uniform oily liquid as a binder;

[0048] (2) Evenly mix the binder with the solder powder obtained in Embodiment 1 or 2 to obtain a solder paste, wherein the additive amount of the binder is 45% to 80% of the weight of the solder.

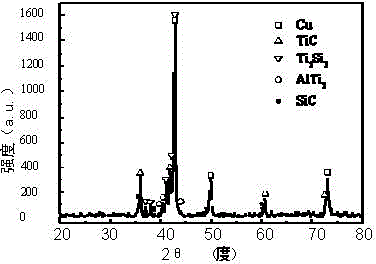

[0049] Practical effect of solder

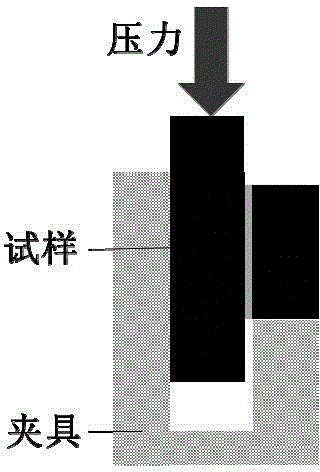

[0050] The solder has been used to study the joining of 3D needled C / SiC composites themselves and 3D braided C / SiC composites with niobium alloy (C-103) and metallic niobium. During the brazing process, the vacuum degree is 6×10 -3 Pa, the heating and cooling rate is 10°C / min, and the performance of the brazed joint is as follows.

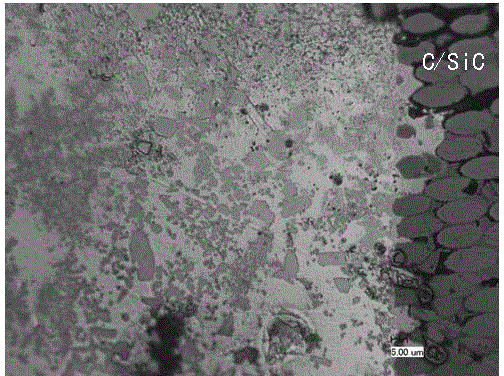

[0051] (1) Self-connection of 3D needle-punched C / SiC composites

[0052] (1) The three-dimensional acupuncture C / SiC composite material (fiber volume fraction 27% ~ 28%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com