Storage battery partition plate and pregnant solution type storage battery

A battery separator and separator technology, which is applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc., can solve the problems of reducing battery oxygen recombination efficiency, increasing battery water loss, weak isolation, etc., to achieve Improve continuous production efficiency, improve oxygen recombination efficiency, and strong isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Battery separator processing and flooded battery assembly and operation steps

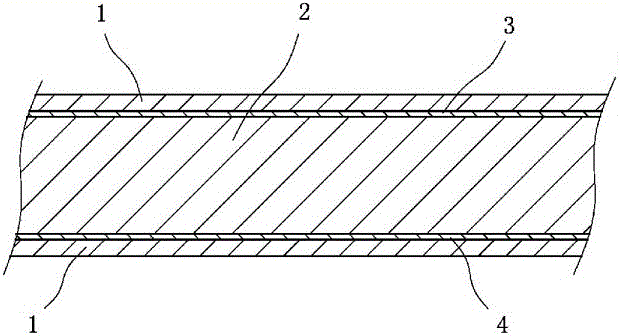

[0040] see figure 1 , figure 1 It is a cross-sectional view of a battery composite separator currently used in the industry.

[0041] like figure 1 As shown, the upper and lower sides of the PE separator layer (2) and the surface of the upper rib (3) and the lower rib (4) are coated with a composite separator adhesive material commonly used in the industry, and then the AGM separator layer (1 ) bonded to the upper and lower sides of the PE separator layer (2) to obtain the battery composite separator currently used in the industry. Because the mechanical strength and puncture resistance of the separator produced by the above technical solution are inconsistent, it can only be processed into a sheet-type separator, and the processed sheet-type separator is assembled to form a flooded battery.

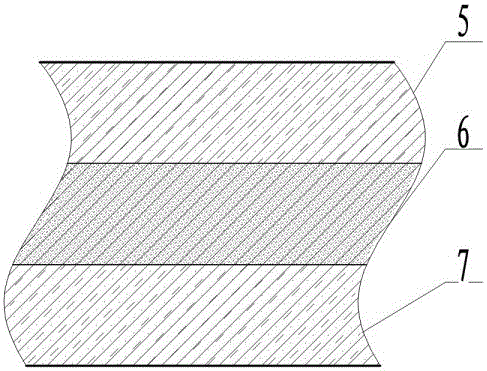

[0042] see figure 2 , figure 2 It is a sectional view of the battery separator disclosed in...

Embodiment 2

[0047] Battery separator processing and flooded battery assembly and operation steps

[0048] see figure 1 , figure 1 It is a cross-sectional view of a battery composite separator currently used in the industry.

[0049] like figure 1 As shown, the upper and lower sides of the PE separator layer (2) and the surface of the upper rib (3) and the lower rib (4) are coated with a composite separator adhesive material commonly used in the industry, and then the AGM separator layer (1 ) bonded to the upper and lower sides of the PE separator layer (2) to obtain the battery composite separator currently used in the industry. Because the mechanical strength and puncture resistance of the separator produced by the above technical solution are inconsistent, it can only be processed into a sheet-type separator, and the processed sheet-type separator is assembled to form a flooded battery.

[0050] see figure 2 , figure 2 It is a sectional view of the battery separator disclosed in...

Embodiment 3

[0055] Battery separator processing and flooded battery assembly and operation steps

[0056] see figure 1 , figure 1 It is a cross-sectional view of a battery composite separator currently used in the industry.

[0057] like figure 1 As shown, the upper and lower sides of the PE separator layer (2) and the surface of the upper rib (3) and the lower rib (4) are coated with a composite separator adhesive material commonly used in the industry, and then the AGM separator layer (1 ) bonded to the upper and lower sides of the PE separator layer (2) to obtain the battery composite separator currently used in the industry. Because the mechanical strength and puncture resistance of the separator produced by the above technical solution are inconsistent, it can only be processed into a sheet-type separator, and the processed sheet-type separator is assembled to form a flooded battery.

[0058] see figure 2 , figure 2 It is a sectional view of the battery separator disclosed in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com