Three-dimensional jacquard weave bulging cover

A jacquard drum cover, three-dimensional technology, applied in textiles and papermaking, non-woven fabrics, needle punching machines, etc., can solve the problems of single appearance, slow liquid absorption, no three-dimensional effect, etc., and achieve good moisture absorption performance and liquid absorption speed. Fast, three-dimensional effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

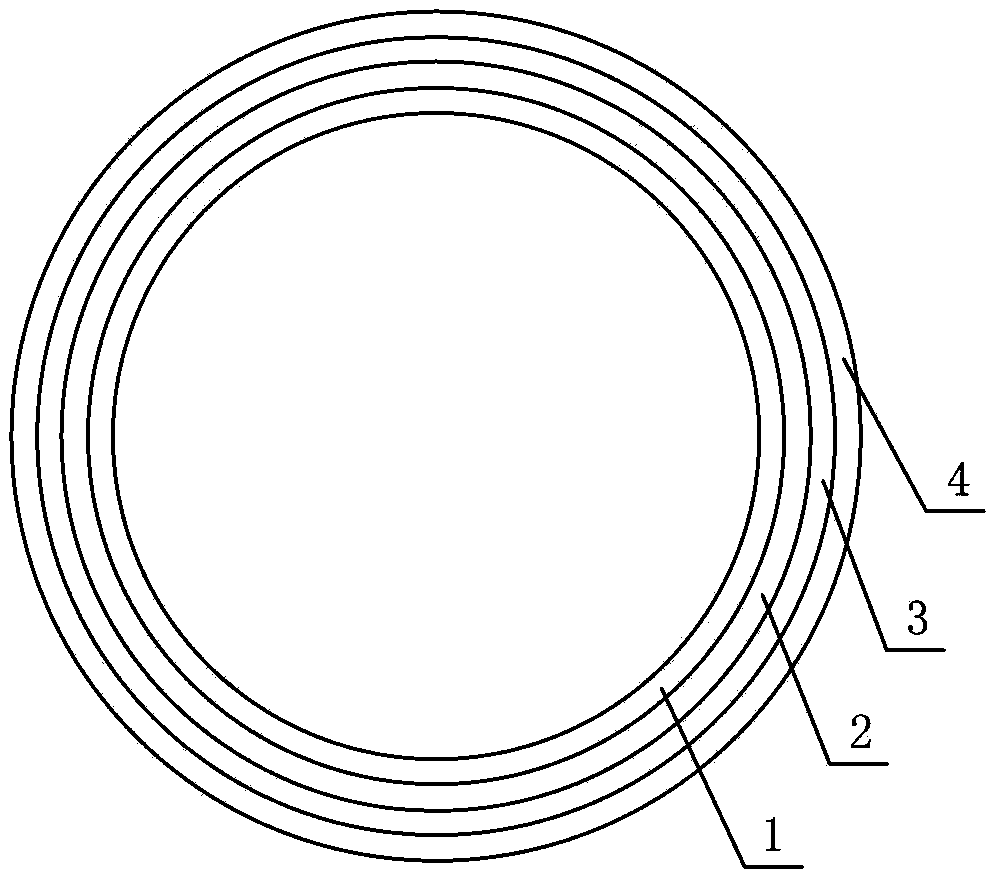

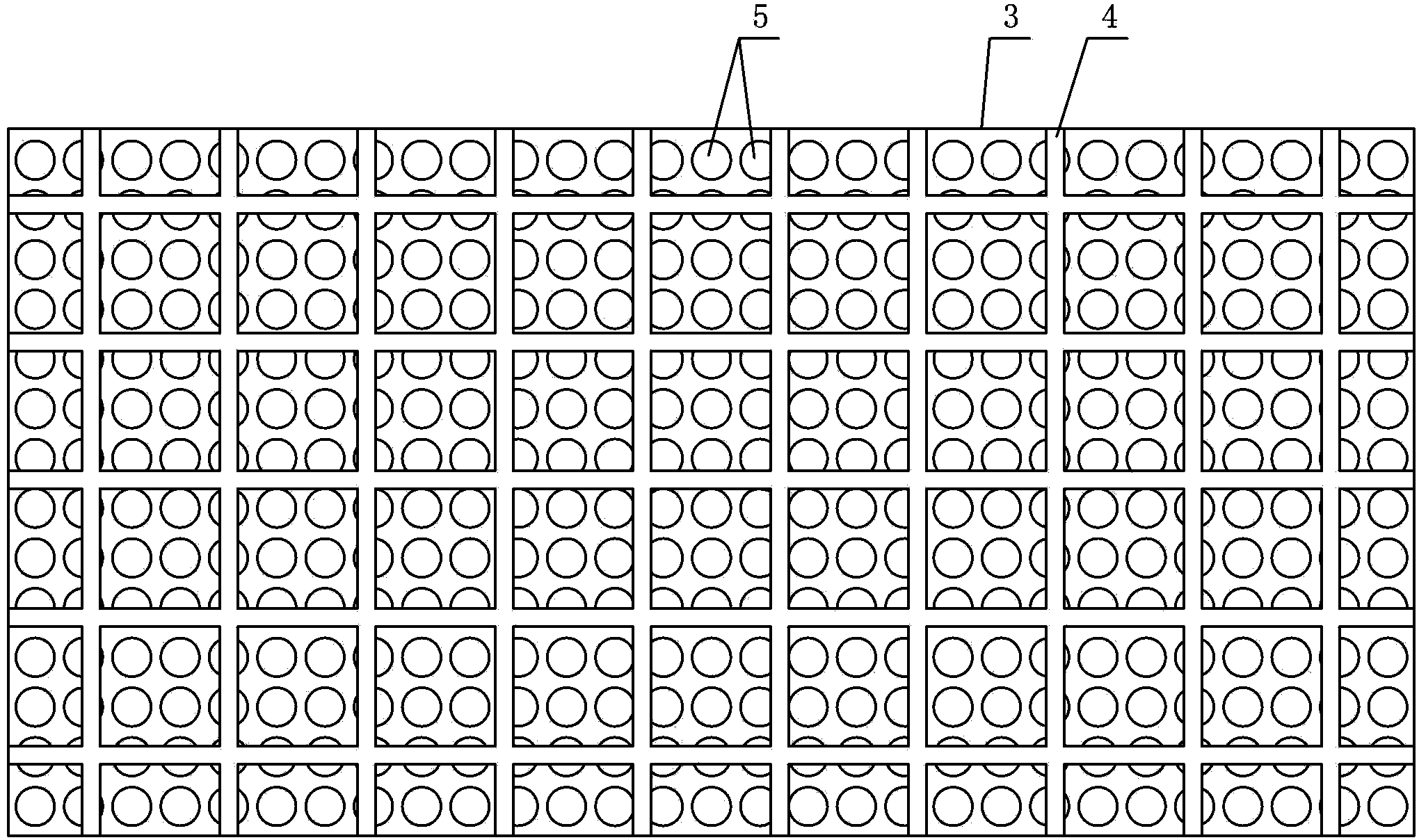

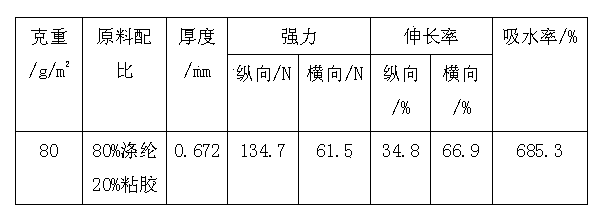

[0015] Such as figure 1 , figure 2 As shown, the three-dimensional jacquard drum cover of the present invention comprises a support cover 1, a lining net 2, a net cover 3, and a grid nickel net 4 fixedly arranged successively from the inside to the outside, that is, the support cover 1, the lining net 2, the net cover 3, The square nickel meshes 4 are sequentially compounded and fixedly connected. Several mesh holes 5 are provided on the mesh cover 3, and the mesh holes 5 are 24 meshes. Mesh holes 5 are evenly covered with net cover 3 . The mesh of square nickel mesh 4 is 2.5 mesh, and liner mesh 2 is 14 mesh stainless steel mesh.

[0016] The spunlace non-woven fabric produced by the three-dimensional jacquard drum cover of the invention not only has three-dimensional effect, but also has soft hand feeling, good hydrophilicity and hygroscopicity, and fast liquid absorption speed.

[0017] The above-mentioned embodiments are only used to explain the inventive concept of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com