Fiberglass membrane of lead-acid battery

A technology of lead-acid battery and glass fiber, which is applied in the direction of battery components, circuits, electrical components, etc. It can solve the problems of affecting the cycle life of the battery, the poor air permeability of the polyolefin diaphragm, and the inability to meet the rapid charging and discharging of the battery. Achieve the effects of low oxidation resistance, good hydrophilicity and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

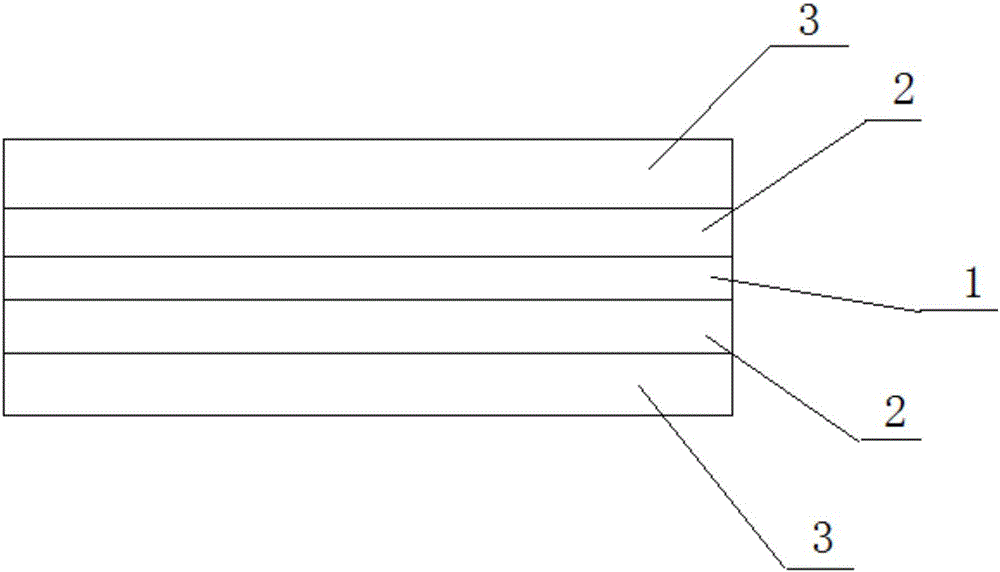

[0016] Glass fiber diaphragm for lead-acid batteries, see figure 1 , Including a glass fiber and polyvinyl alcohol fiber composite layer 1, a polymer and water-soluble resin composite layer on both surfaces of the glass fiber and polyvinyl alcohol fiber composite layer 2, a polymer and water-soluble resin composite layer outside Nanoparticle coating on the surface3.

[0017] In the composite layer of glass fiber and polyvinyl alcohol fiber, the mass ratio of glass fiber to polyvinyl alcohol is 2:1.

[0018] In the polymer and water-soluble resin composite layer, the polymer is polypropylene and polyethylene terephthalate with a mass ratio of 1:1, and the water-soluble resin is polyethylene with a mass ratio of 1:2:1 Mixture of alcohol, polyvinylpyrrolidone and polyethylene oxide.

[0019] The nanoparticle coating is a coating of ceramic particles and a resin composite nanoparticle with a mass ratio of 1:3; the ceramic particles are a mixture of aluminum oxide, silicon oxide, and ti...

Embodiment 2

[0025] Glass fiber diaphragm for lead-acid batteries, see figure 1 , Including a glass fiber and polyvinyl alcohol fiber composite layer 1, a polymer and water-soluble resin composite layer on both surfaces of the glass fiber and polyvinyl alcohol fiber composite layer 2, a polymer and water-soluble resin composite layer outside Nanoparticle coating on the surface3.

[0026] In the composite layer of glass fiber and polyvinyl alcohol fiber, the mass ratio of glass fiber to polyvinyl alcohol is 1:1.

[0027] In the polymer and water-soluble resin composite layer, the polymer is one or a mixture of several kinds of polyethylene, and the water-soluble resin is hydroxymethyl cellulose and cellulose acetate with a mass ratio of 1:1:2 , A mixture of cellulose acetate butyrate.

[0028] The nanoparticle coating is a ceramic particle and a resin composite nanoparticle coating with a mass ratio of 1:2; the ceramic particles are a mixture of zirconia and barium titanate with a mass ratio of ...

Embodiment 3

[0031] Glass fiber diaphragm for lead-acid batteries, see figure 1 , Including a glass fiber and polyvinyl alcohol fiber composite layer 1, a polymer and water-soluble resin composite layer set on both surfaces of the glass fiber and polyvinyl alcohol fiber composite layer 2, a polymer and water-soluble resin composite layer outside Nanoparticle coating on the surface3.

[0032] In the composite layer of glass fiber and polyvinyl alcohol fiber, the mass ratio of glass fiber to polyvinyl alcohol is 3:1.

[0033] In the composite layer of polymer and water-soluble resin, the polymer is polyimide, and the water-soluble resin is a mixture of cellulose acetate butyrate, cellulose acetate propionate, and pullulan with a mass ratio of 1:1:1. mixture.

[0034] The nanoparticle coating is a ceramic particle and a resin composite nanoparticle coating with a mass ratio of 1:4; the ceramic particles are barium sulfate; and the resin is polystyrene.

[0035] The preparation method is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com