Self-crosslinking acrylate emulsion and preparation method thereof

An acrylate and self-crosslinking technology, applied in the direction of ester copolymer adhesives, adhesive types, etc., can solve the problem of ultra-fine glass fiber separators with high potassium permanganate reduction content, ultra-fine glass fiber separators Slow liquid absorption speed, affecting product performance and other problems, to achieve the effect of easy control of reaction, reduction of residual amount, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0018] The preparation method of the self-crosslinking acrylate emulsion of the present embodiment has the following steps:

[0019] ① Pre-emulsification:

[0020] At ambient temperature (0-40°C, the same below), add 60kg of deionized water and 5kg of emulsifier A to the pre-emulsification tank equipped with a stirrer, reflux condenser and thermometer (this example uses American AEROSOL A-501 produced by Cytec), stirred at a speed of 150 rpm for 15 minutes.

[0021] After stirring evenly, add 3kg of methacrylic acid, 7kg of diacetone acrylamide, 80kg of methyl methacrylate and 130kg of ethyl acrylate in sequence. The rotating speed was reduced to 100 rpm and stirred for 10 minutes to obtain 285 kg of pre-emulsion for use.

[0022] ②Emulsification:

[0023] First, at ambient temperature, add 140kg of deionized water and 0.5kg of emulsifier B into a reaction kettle with a stirrer, reflux condenser and thermometer (this embodiment uses AEROSOL MA produced by Cytec Corporation ...

Embodiment 2~ Embodiment 3)

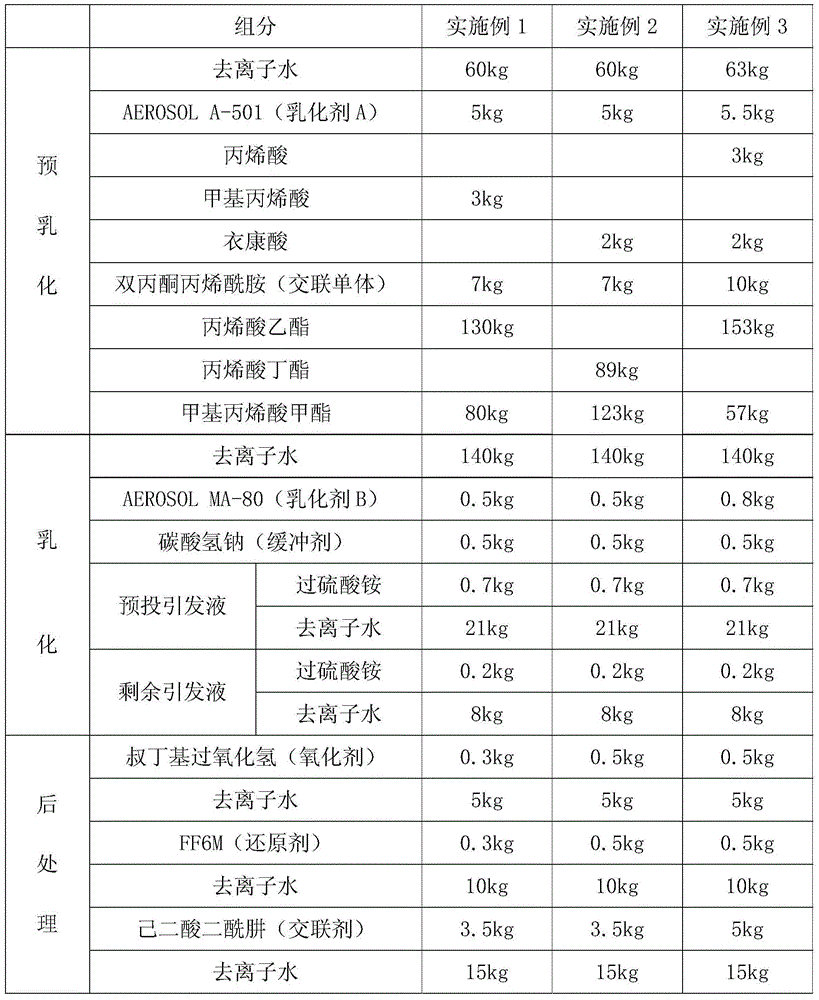

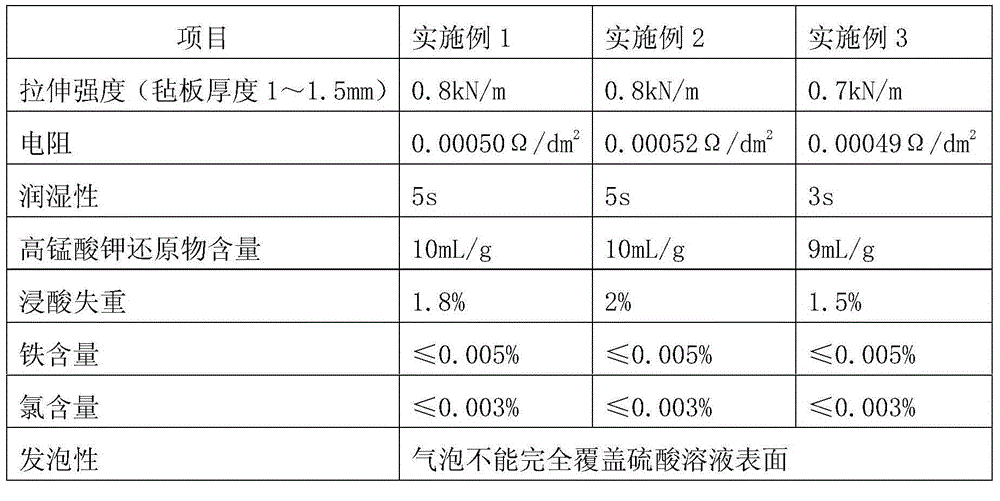

[0031] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0032] Table 1

[0033]

[0034] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com