Positive plate, manufacturing method thereof and battery

A positive electrode sheet and a positive electrode current collector technology are applied to the positive electrode sheet and its manufacturing method, and the battery field, which can solve the problems of low production turnover efficiency, diving cycle life, elongated production cycle, etc., so as to improve the turnover efficiency and improve the liquid absorption speed. , the effect of accelerating the infiltration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

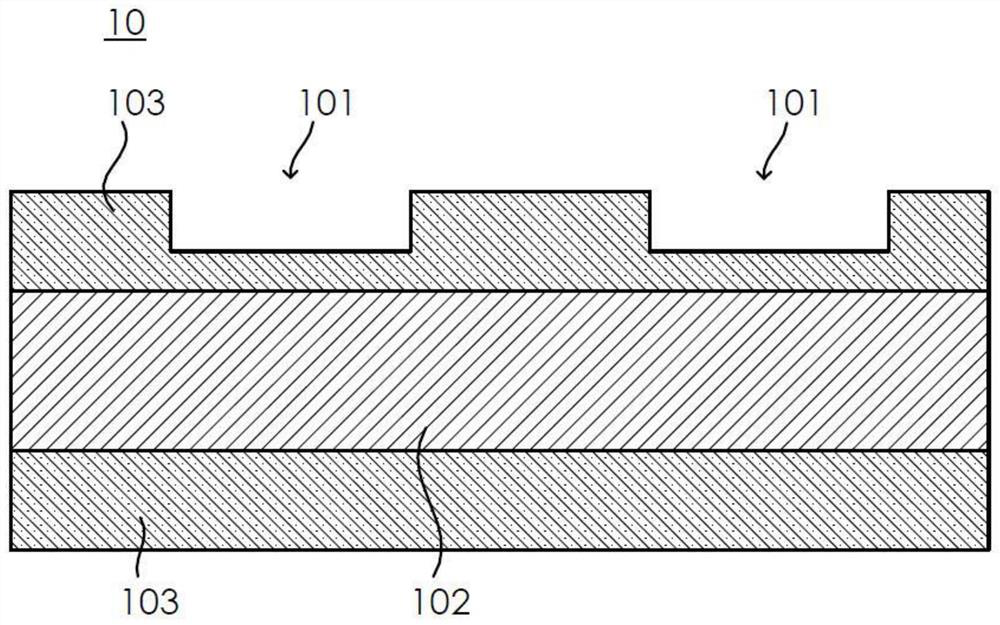

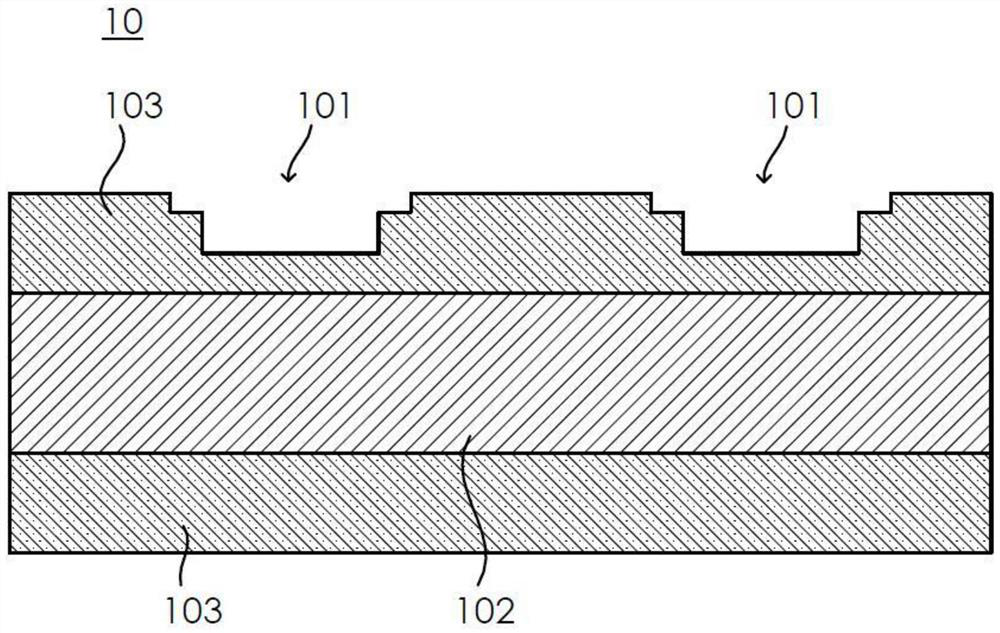

[0054] A slurry coating is evenly coated on a copper foil to form a graphite negative electrode sheet, and the copper foil may be, for example, 8 microns thick.

[0055] Rolling the graphite negative electrode sheet comprising the copper foil and the second coating, the thickness of the rolled graphite negative electrode sheet is 0.097 mm, wherein the negative active material in the second coating is The content is 97%.

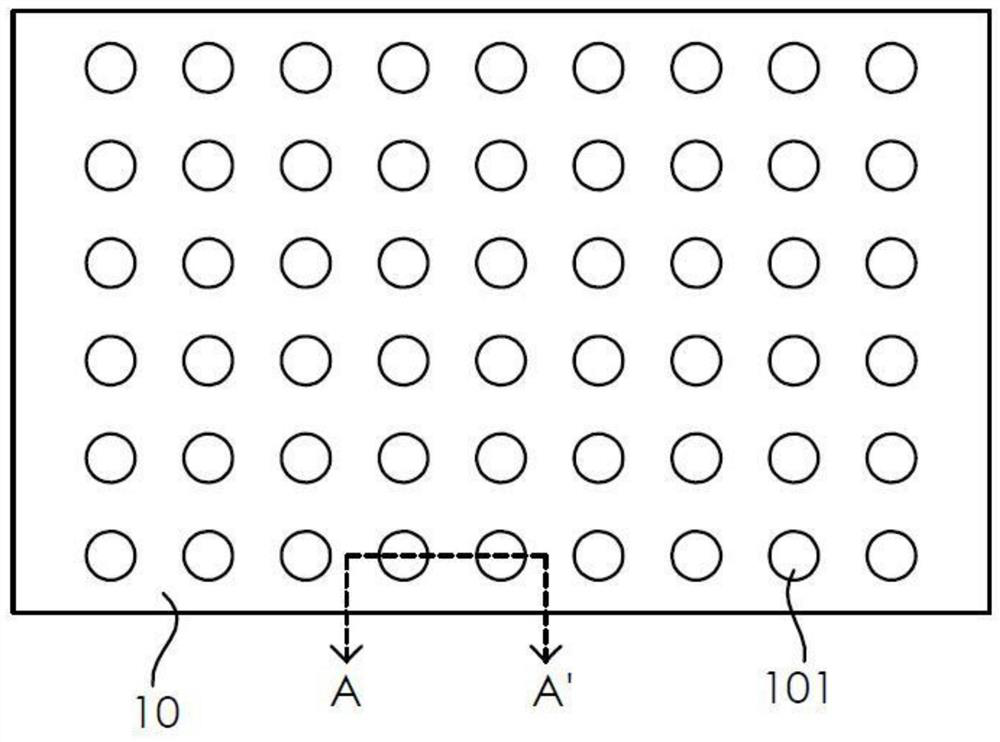

[0056] Carry out laser dot matrix drilling (the depressed portion 101) to the graphite negative plate, the wavelength of the laser is 355nm, the pulse power is 3 watts, the pulse repetition frequency is 20 kHz, the pulse width is 25 nanoseconds, and the pulse The number is 5, and to form the aperture (the diameter of the smallest circumscribed circle of the shape corresponding to the opening of the recessed portion 101) is 15 microns, and the hole depth (the depth of the recessed portion 101) is 30 microns, adjacent holes The pitch (the distance between the ...

Embodiment 2

[0061] Embodiment 2 is similar to embodiment 1, the difference is:

[0062] The pulse power of the laser is 2 watts, the pulse repetition frequency is 20 kHz, the pulse width is 10 nanoseconds, and the number of pulses is 5, so as to form an aperture with a diameter of 5 microns, a hole depth of 30 microns, and a distance between adjacent holes of 0.5 mm matrix round holes.

Embodiment 3

[0064] Embodiment 3 is similar to any of the foregoing embodiments, except that:

[0065] The pulse power of the laser is 4 watts, the pulse repetition frequency is 20 kilohertz, the pulse width is 30 nanoseconds, and the number of pulses is 5, so that the aperture is 30 microns, the hole depth is 30 microns, and the distance between adjacent holes is 0.5 mm matrix round holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com