Mask base cloth, preparation method thereof and mask containing mask base cloth

A mask and base fabric technology, applied in the field of skin care products, can solve problems such as easy deformation, and achieve the effects of strong water-locking ability, high liquid absorption rate, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention also provides the preparation method of above-mentioned facial mask base cloth, and described preparation method comprises the following steps:

[0035] The synergist is taken and prepared into a solution; the solution is coated on the fiber substrate; and dried.

[0036] The facial mask base cloth prepared in the embodiment of the present invention has a small relative deviation in grammage and uniform thickness.

[0037] Preferably, in the solution, the synergist has a mass percentage of 15-30%.

[0038] Preferably, the drying temperature is 100-120°C.

[0039] Preferably, the coating is carried out in a coating device including a sizing tank and a sizing roller, and the process includes: pouring the solution into the sizing tank, and the sizing roller drives the fiber matrix to pass through the solution.

[0040] Preferably, the speed at which the sizing roller drives the fiber matrix through the solution is 20-40 m / min.

[...

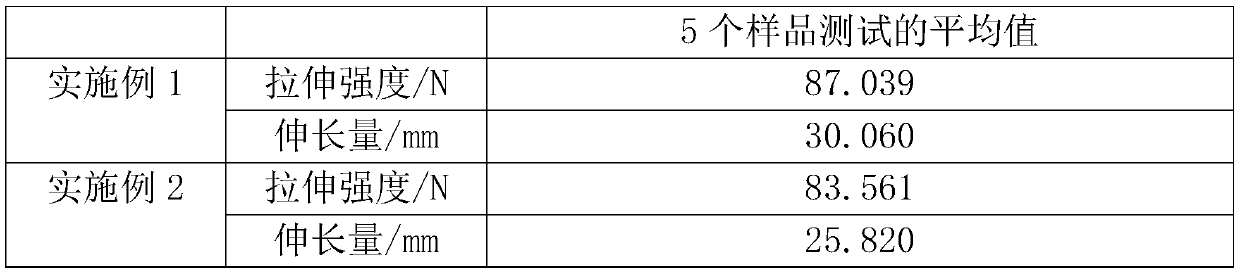

Embodiment 1

[0044] This embodiment provides a facial mask base fabric and a preparation method thereof.

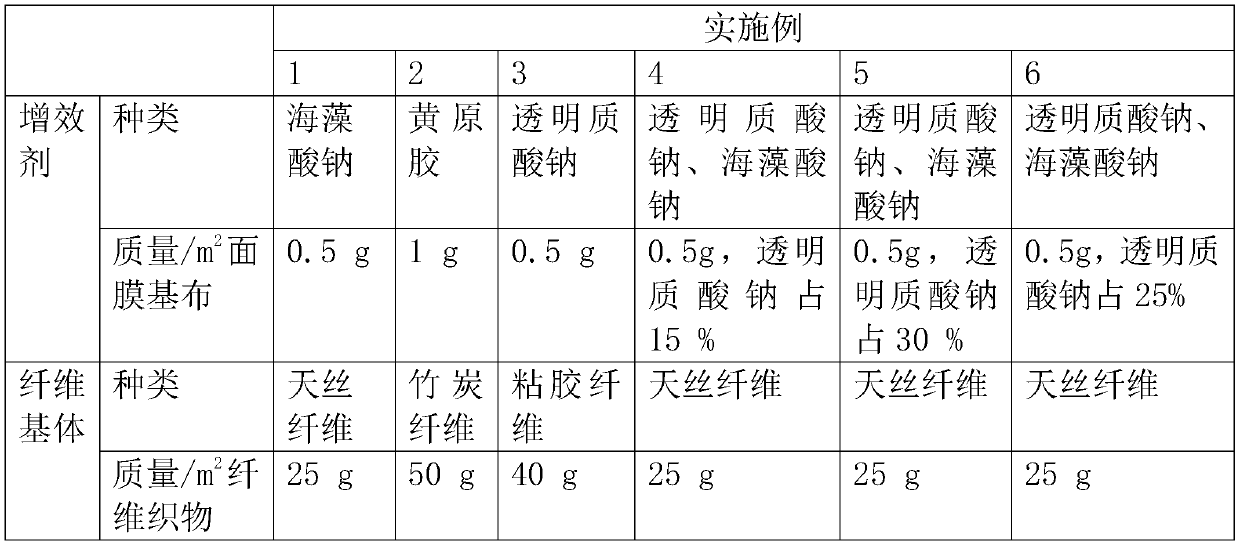

[0045]The mask base cloth of the present embodiment (see table 2) comprises fibrous matrix, is attached with synergist on the described fibrous matrix, wherein:

[0046] The synergist is sodium alginate;

[0047] The fibers contained in the fiber matrix are tencel fibers, and the fiber matrix is purchased from Austrian Lenzing Company, and the quality of the fiber matrix per square meter is 25g;

[0048] The quality of the synergist contained in the mask base cloth per square meter is 0.5g.

[0049] The preparation method of the mask base cloth of the present embodiment comprises the steps:

[0050] (1) Take sodium alginate and prepare an aqueous solution of sodium alginate with a mass percent content of 25%;

[0051] (2) The above-mentioned sodium alginate aqueous solution is transported to the sizing tank, and the rotating speed of the sizing roller is 30 m / min. The speed is ro...

Embodiment 2

[0059] This embodiment provides a facial mask base fabric and a preparation method thereof.

[0060] The mask base cloth of the present embodiment (see table 2) comprises fibrous matrix, is attached with synergist on the described fibrous matrix, wherein:

[0061] The synergist is xanthan gum;

[0062] The fiber contained in the fiber matrix is bamboo charcoal fiber, and the quality of this fiber matrix per square meter is 50g;

[0063] The quality of the synergist contained in the facial mask base cloth per square meter is 1g.

[0064] The preparation method of the mask base cloth of the present embodiment comprises the steps:

[0065] (1) Get xanthan gum and prepare an aqueous solution of xanthan gum with a mass percentage of 15%;

[0066] (2) The above-mentioned xanthan gum aqueous solution is transported in the sizing tank, the rotating speed of the sizing roller is to rotate at a speed of 20 meters per minute, and a distance of 200mm is formed between the upper rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com