Process for manufacturing phosphor bronze-steel bimetal bearing material with phosphor content more than 0.1%

A bearing material and manufacturing process technology, applied in the field of phosphor bronze-steel bimetal bearing material manufacturing process, can solve the problems of non-ferrous metal consumption, low yield and low production efficiency, and achieve high production efficiency, stable mechanical performance, Achieve the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

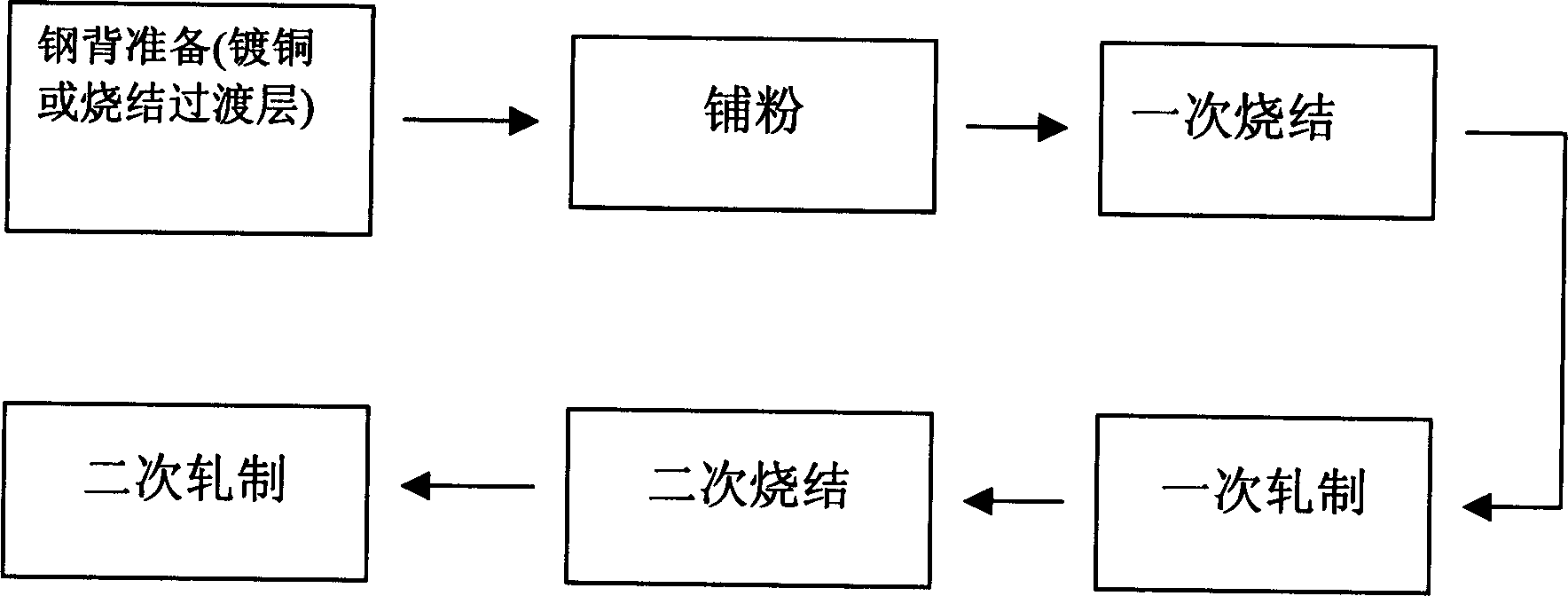

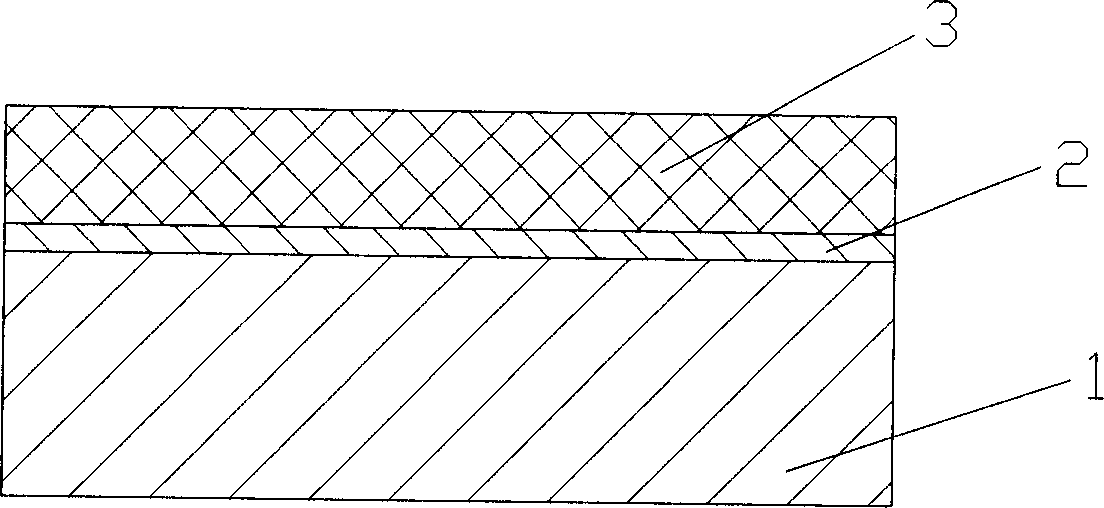

[0049] Such as figure 1 , 2 As shown, the phosphor bronze-steel bimetal bearing material manufacturing process with a phosphorus content greater than 0.1% of the present invention effectively solves two major problems in the prior art: one is when the phosphorus content in the phosphor bronze exceeds 0.1%, The bonding fastness between the phosphor bronze alloy layer and the steel back drops sharply; the second is that the phosphorus in the phosphor bronze is easily burned during the sintering process.

[0050]It is to set a transition layer 2 with an appropriate thickness on the pre-prepared carbon structural steel back 1 of the required grade and thickness, and then evenly spread the phosphor bronze alloy powder with a certain phosphorus content on the steel back, so that It has a certain spread thickness, and it is sintered once to make the phosphor bronze alloy powder adhere to the steel back 1 to form the phosphor bronze alloy layer 3; then it is rolled once to make the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com