Multilayer composite material and manufacturing method thereof

A technology of multi-layer composite materials and production methods, applied in the field of multi-layer composite material production, can solve the problems of difficult control of overall thickness uniformity, delamination, delamination, etc., and achieve the solution of difficult control of thickness uniformity, dimensional accuracy and consistency High resistance, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

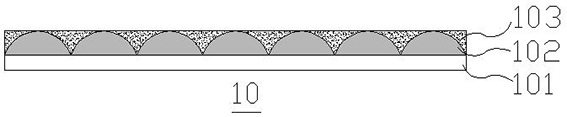

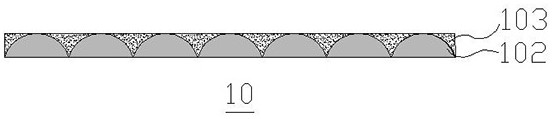

[0042] Such as figure 1 Shown is a schematic cross-sectional view of the structure of a three-layer composite material containing a substrate layer in Example 1 of the present invention. The three-layer composite material is composed of a substrate layer 101, a microstructure layer 102 and a leveling layer 103 , the microstructure layer 102 includes several identical microstructures, the cross-sectional shape of the microstructures is a semicircular arc, and the cross-sectional shape, tooth pitch and tooth height of the microstructures on the entire microstructure layer 102 are all the same. The microstructure layer 102 is composed of a plurality of linear microstructure arrays. The leveling layer 103 fills and leveles all the arc-shaped tooth-shaped recessed areas of the microstructure array on the entire microstructure layer 102 .

[0043] Further, as figure 2Shown is a schematic cross-sectional view of the structure of a two-layer composite material without a substrate l...

Embodiment 2

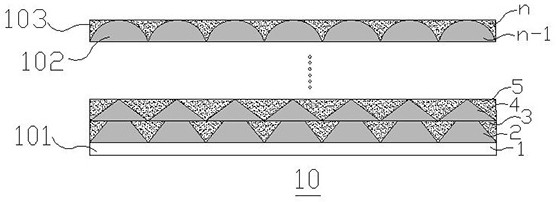

[0051] Such as Figure 4 Shown is the cross-sectional view of the structure of the multilayer composite material in Example 2 of the present invention. The multilayer composite material is composed of one substrate layer, three microstructure layers and three filler layers, and the microstructure layers and filler layers are alternately arranged on Substrate surface. Such as Figure 4 As shown in a, all the microstructures 1021 of the microstructure layer have the same cross-sectional shape, which is semicircular. Such as Figure 4 As shown in b, the cross-sectional shape of the microstructure 1021 of the same microstructure layer in the three-layer microstructure layer on the multilayer composite material is completely the same; the cross-sectional shape of the microstructure 1021 of only two microstructure layers in different microstructure layers is the same, showing semi-circular arc; the microstructure 1021 of the other microstructure layer has a different cross-sectio...

Embodiment 3

[0056] Such as Figure 5 Shown is a schematic cross-sectional view of the structure of the multi-layer composite material in Example 3 of the present invention.

[0057] Such as Figure 5 As shown in a, the multilayer composite material is composed of one substrate layer, three microstructure layers and three leveling layers, and the tooth pitch P of the microstructures 1021 on the three microstructure layers are all the same.

[0058] Such as Figure 5 As shown in b, the multilayer composite material is composed of one substrate layer, three microstructure layers and three leveling layers, and the tooth pitch P of the microstructure 1021 on the three microstructure layers is only two layers are the same, and the tooth pitch P of the other layer is different. In this case, the pitch of each microstructure array tooth shape on the multi-layer composite material is the same as that between the layer and the interlayer. Of course, when the composite material has more layers, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com