Novel bromamine acid synthesis process

A kind of bromine acid and new technology technology, applied in the field of organic synthesis, can solve the problems such as low quality and low yield of bromine acid products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

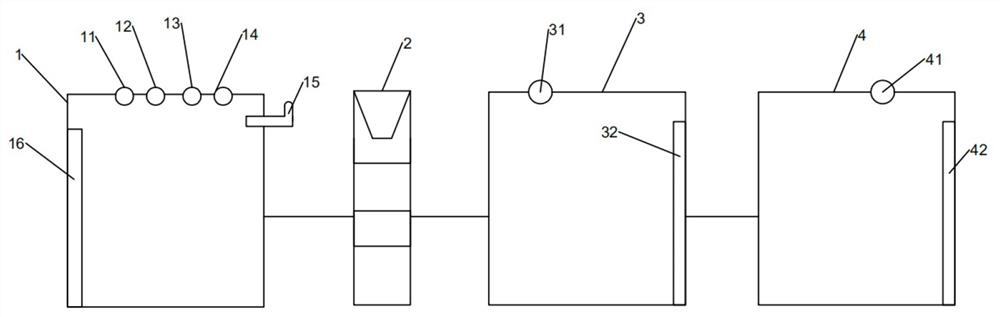

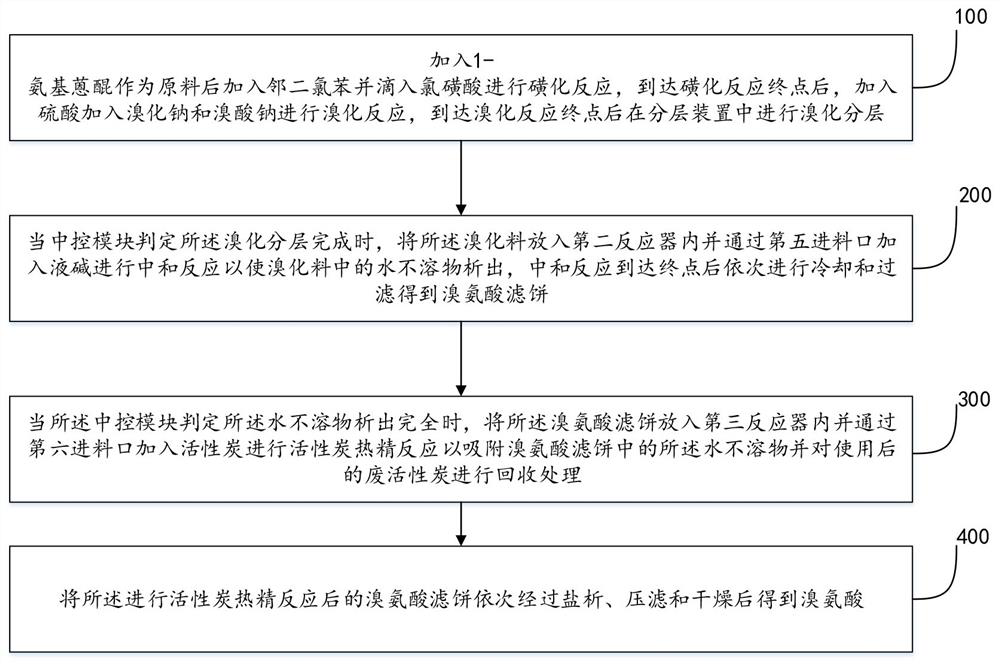

Method used

Image

Examples

Embodiment 1

[0173] After bromination stratification, do different neutralization pH tests on the brominated material:

[0174] Take the brominated stratified material layer, add alkali to neutralize to PH6-7 and PH=9, heat to boiling, retest the pH, and find that the pH will decrease to varying degrees, add liquid alkali to adjust to the specified value, and cool to 50 ℃, filter, take the filter cake for insoluble matter test, observe whether there is insoluble matter precipitation, and the amount of precipitation; and neutralize the salting-out filtrate at pH6-7 with liquid caustic soda to neutralize the filtrate pH9.35, filter, Observe whether any insoluble matter that has not been completely precipitated is re-precipitated under alkaline conditions.

[0175] in conclusion:

[0176] When neutralizing and adjusting the pH to 6-7, there is a small amount of black insoluble matter in the bromine filter cake;

[0177] When the pH is adjusted to 9, there are more brown-black insoluble matt...

Embodiment 2

[0181] Material test after neutralization and heat refining:

[0182] Test the PH and water insoluble matter of the material after heat refining. The material PH after heat refining is about 4-5. After testing, there is no water insoluble matter. When adding alkali to adjust PH=7, there will be a large amount of insoluble matter; therefore, The insoluble matter always exists in the system, and the insoluble matter is in a dissolved state when the pH is 4-5. When the pH value is controlled, the salting out allows the insoluble matter to remain in the salting out solution.

Embodiment 3

[0184] (1) After activated carbon is refined and blank

[0185] Dissolve about 68g of used activated carbon in 200ml of hot water, add hydrochloric acid, filter, the filtrate is measured at PH=1.6, add liquid caustic soda, and a large amount of black insoluble matter is precipitated; the results show that activated carbon adsorbs more insoluble matter.

[0186] (2) Activated carbon blank test

[0187] Take 30g of fresh activated carbon and put it in 200ml of water. Before adding activated carbon, the pH of the water is 8.05. After adding activated carbon, the pH of the water is 2.7. Add hydrochloric acid, filter, and measure the pH of the filtrate. A small amount of yellow-green insoluble matter; the analysis believes that the trace amount of insoluble matter in the small-scale activated carbon blank test is negligible on the basis of the total volume of 30kg and 5000kg of activated carbon in the workshop;

[0188] The above two groups of experiments concluded that activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com