Gas-liquid separator for sealing compressor

A technology of gas-liquid separator and compressor, which is applied in the direction of machines/engines, liquid variable displacement machines, rotary piston machines, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Reference will now be made in detail to preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

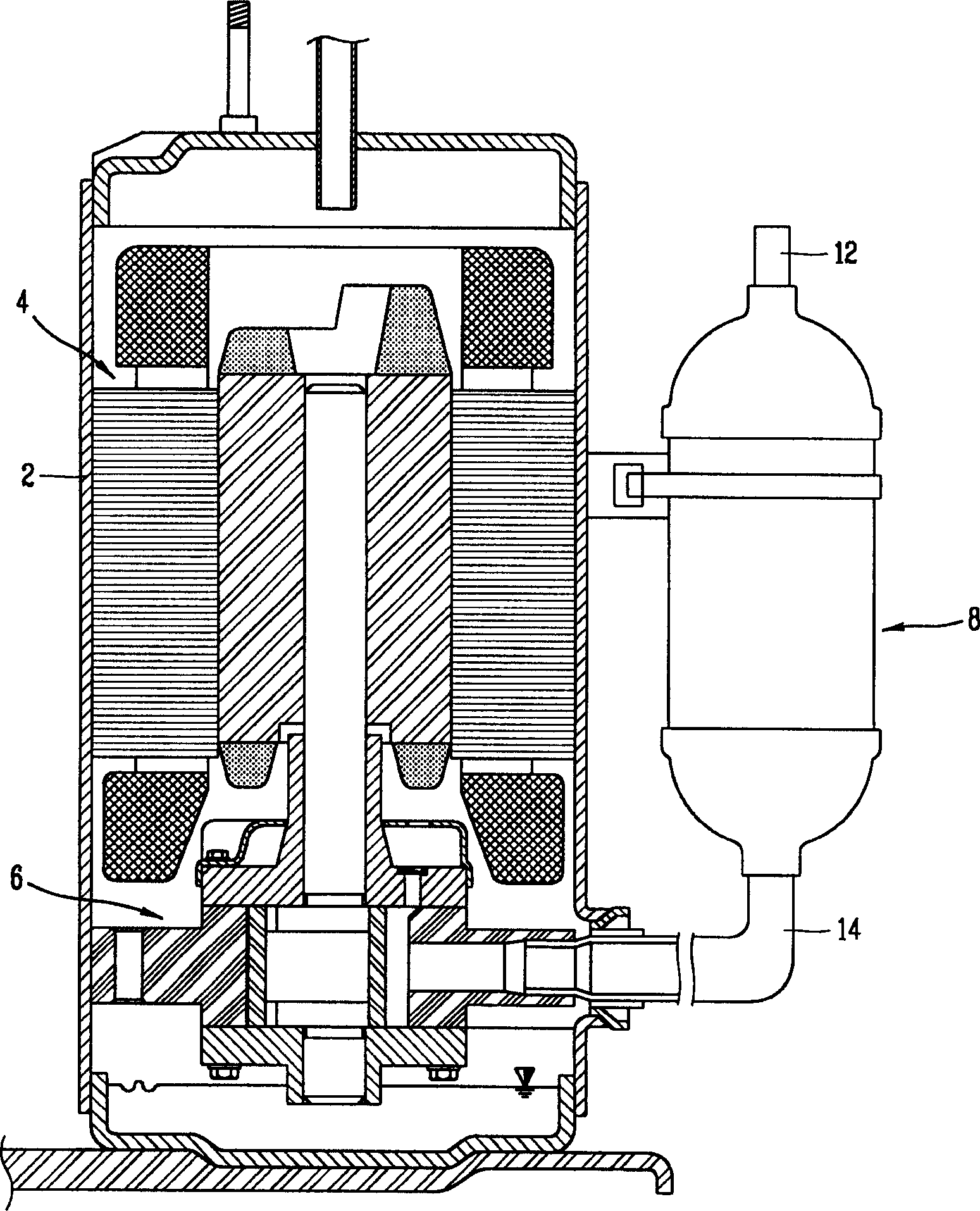

[0032] figure 2 It is a cross-sectional view of a hermetic compressor equipped with a gas-liquid separator of the present invention.

[0033] The hermetic compressor of the present invention comprises: a hermetic shell 2 with a constant space; a drive unit 4 mounted on one side of the shell 2 for generating rotational force; A compression unit 6 that compresses the refrigerant with a driving force;

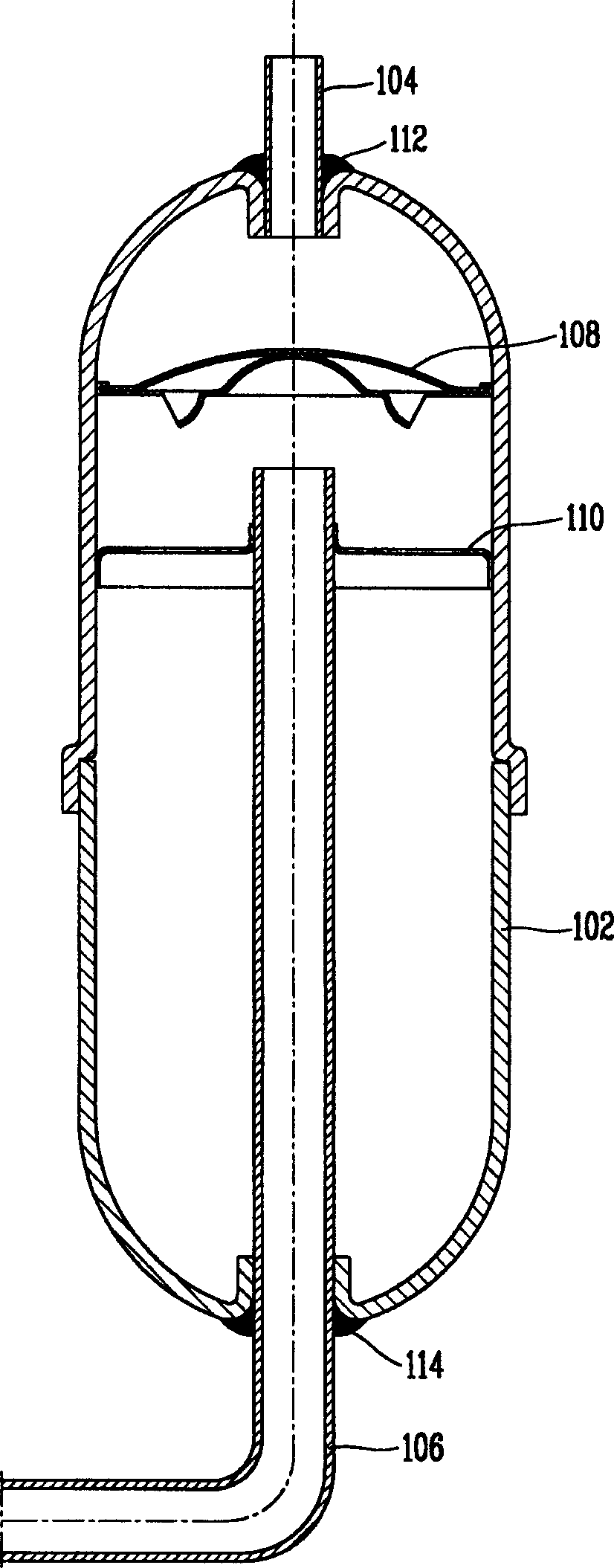

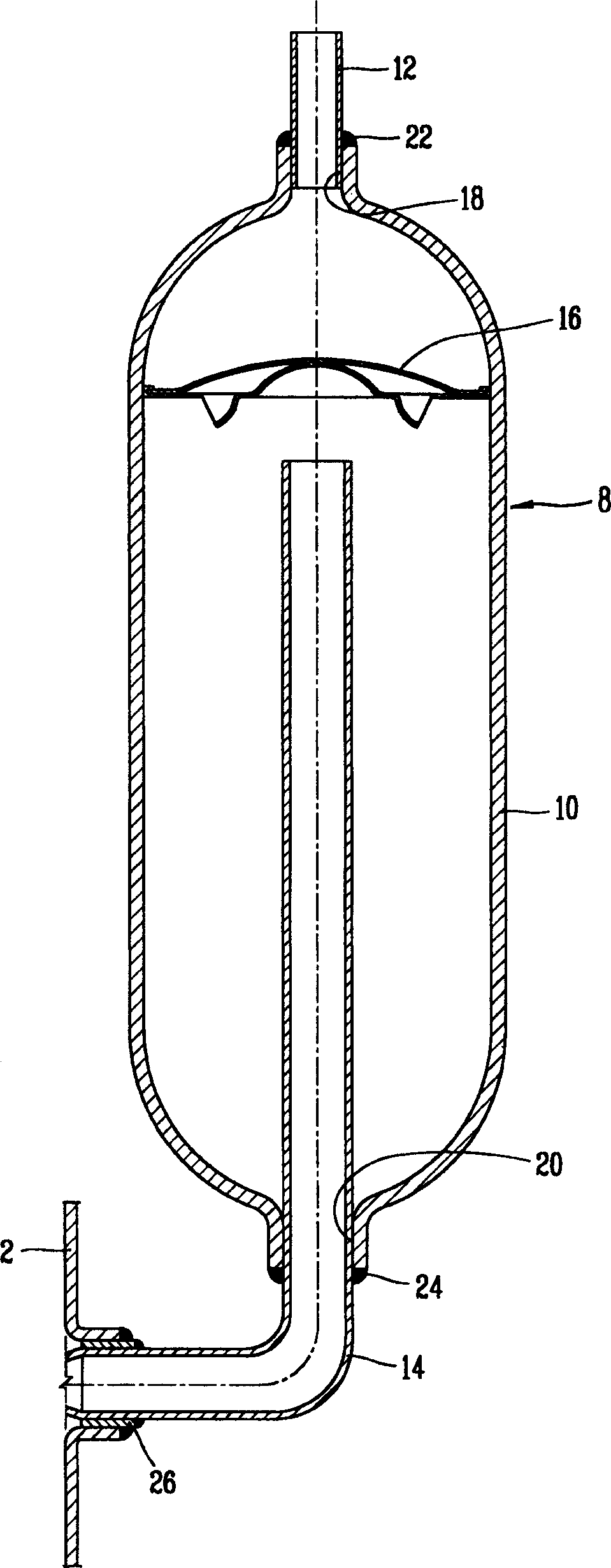

[0034] Such as image 3 As shown, the gas-liquid separator 8 includes: a housing 10 having a constant space for guiding the refrigerant; a suction pipe 12 sealingly connected to the top side of the housing 10 for guiding the refrigerant into the housing 10; and A discharge pipe 14 inserted into the casing 10 at a constant length from the bottom side of the casing 10 is connected to the compressor casing 2 to introduce gas refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com