Phosphor bronze bimetal plate for making bush and process for making same

A production process, phosphor bronze technology, which is applied in the field of engine bearing materials, can solve the problem of volatilization of the alloy layer and steel back, and achieve the effect of improving the running quality of the car, being conducive to environmental protection, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

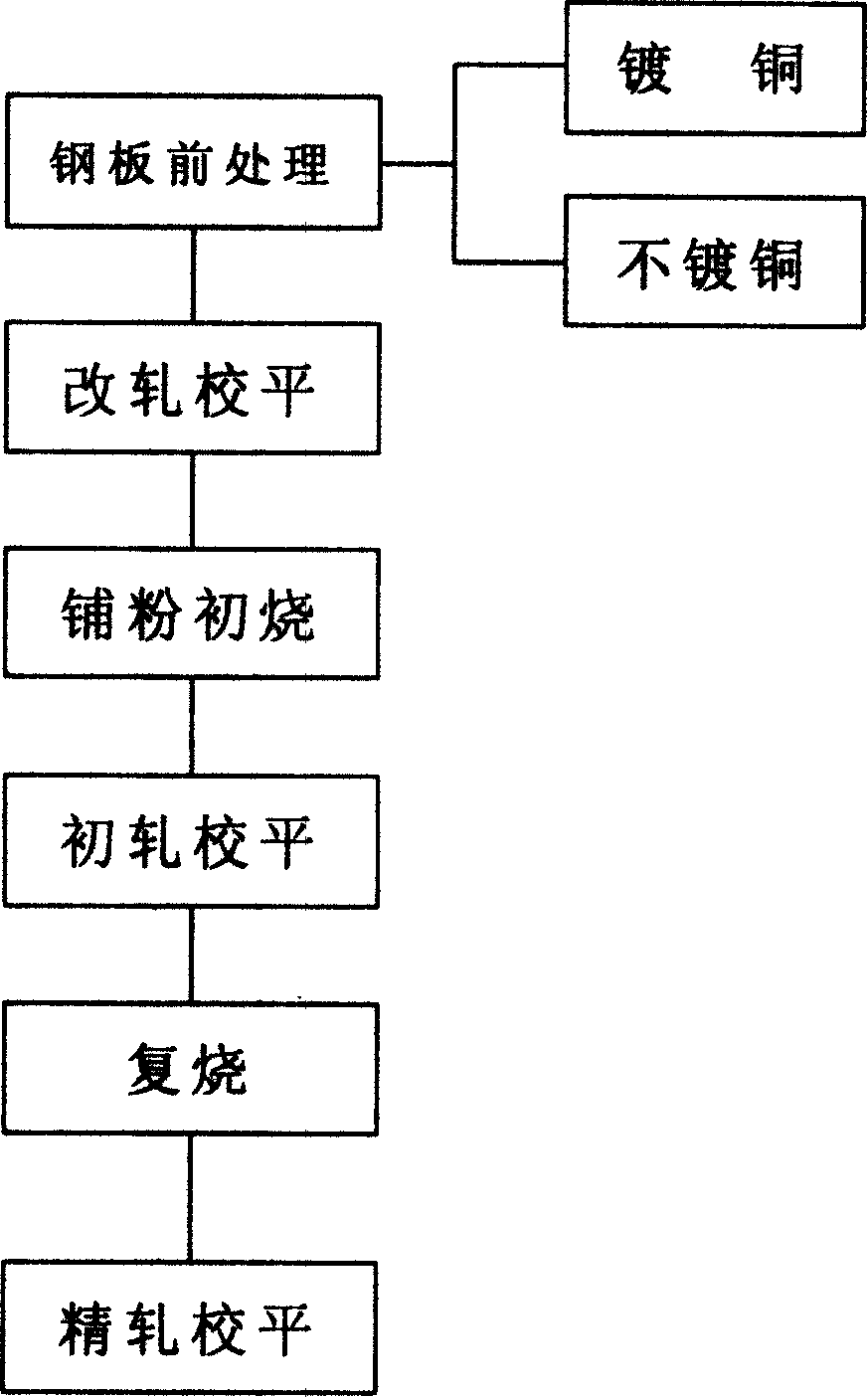

[0015] Embodiment 1: see accompanying drawing.

[0016] 1. Steel plate preparation: choose St 37-2G Brand high-quality carbon structural steel plate, cut the large steel plate into strips of a certain geometric size, and carry out surface treatment for degreasing and derusting;

[0017] 2. Re-rolling and leveling of the steel plate, re-rolling the steel plate to the required thickness and leveling;

[0018] 3. Spread the powder and first burn, the chemical composition is by weight: tin (Sn) 5.5%, phosphorus (P) 0.2%, zinc (Zn) 0.3%, nickel (Ni) 0.2%, iron (Fe) 0.05%, lead Alloy powder with (Pb) 0.2%, copper (Cu) 93.05%, and total impurities 0.5% is evenly spread on the leveled steel plate, and sent into a crawler-type continuous sintering furnace with a temperature of 870°C, under gas protection Carry out initial firing to sinter the Cu-Sn-P alloy powder on the steel plate to form an alloy layer;

[0019] 4. Initial rolling leveling, cold rolling the material after initial ...

Embodiment 2

[0023] Choose St. 37-2G The high-quality carbon structural steel plate of the brand is treated with oil removal, rust removal and copper plating surface treatment. The chemical composition is as follows by weight: tin (Sn) 7%, phosphorus (P) 0.3%, zinc (Zn) 0.05%, copper (Cu ) is 91.3%, and the rest is impurities. The alloy powder is evenly spread on the leveled steel plate, and sent to the crawler type continuous sintering furnace with a temperature of 860 °C for initial firing, and the initially rolled leveled plate is at a temperature of 890 °C Re-burn down. All the other production techniques are the same as example 1.

Embodiment 3

[0025] Choose St. 12 Brand of high-quality carbon structural steel plate, the chemical composition by weight is: tin (Sn) 7%, phosphorus (P) 0.1%, zinc (Zn) 0.8%, copper (Cu) 92.35%, the rest is alloy powder of impurities Spread evenly on the leveled steel plate, and send it into the crawler type continuous sintering furnace with a temperature of 870°C for initial firing, and refire the initially rolled and leveled plate at a temperature of 890°C. All the other production techniques are the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com