High-elasticity low-cost tin-phosphor bronze alloy belt and preparation method thereof

A technology of tin-phosphor bronze and phosphor-copper alloy is applied in the field of tin-phosphor bronze alloy strip and its preparation, which can solve the problems of tin-bronze material plasticity, low resilience, unsatisfactory tin-bronze requirements, unstable grain size and the like, Achieve excellent processing performance, inhibit grain growth, and stabilize high temperature stress relaxation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

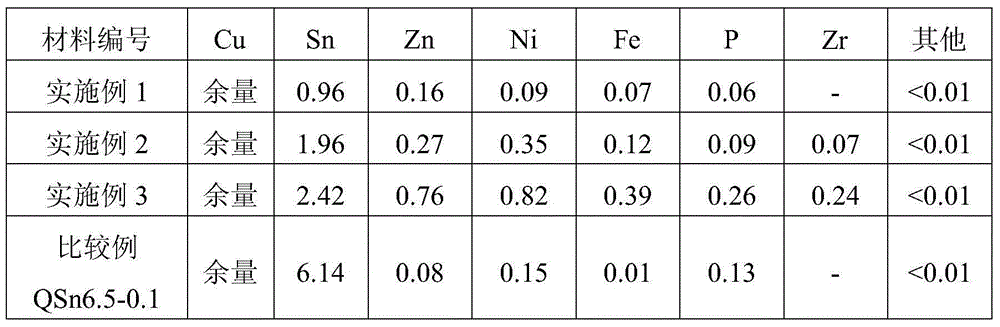

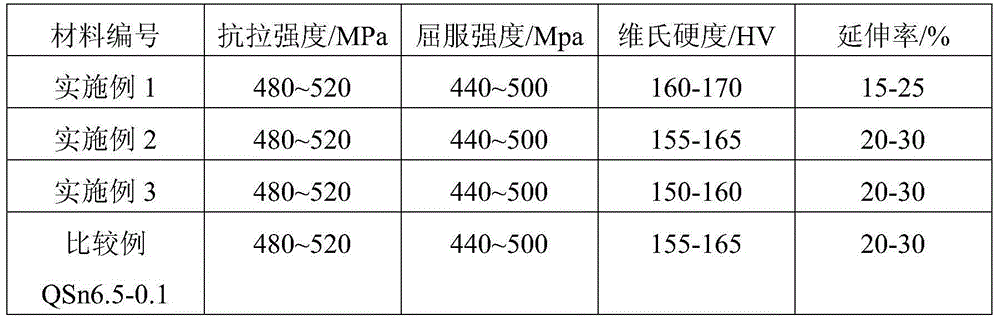

Examples

preparation example Construction

[0028] A method for preparing tin-phosphorus bronze with high elasticity and low cost. The specific steps are as follows: first add electrolytic copper, nickel plate and iron-copper alloy into a cored induction power frequency melting furnace with a melting temperature of 1240-1260°C. After all are melted, The temperature is reduced to 1220-1240℃, and zinc ingots, tin blocks, phosphor copper alloys and copper zirconium alloys are added (when necessary). The phosphor copper alloys and copper zirconium alloys are wrapped in red copper. After all of them are melted, they are tested by spectroscopy and the composition is qualified. , Pass the launder converter to the core induction power frequency holding furnace, after the temperature rises to 1180-1220 ℃, heat preservation and stand for 30-60 minutes, then draw casting, the thickness of the drawn blank is 16.5-17.5mm, the width is 380- 420mm, the casting speed is 150-180mm / min. Next, face milling, 0.4-0.6mm on the upper and lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com