Adhesive composition for electronic cloth edge sealing and preparation method thereof

A composition and adhesive technology, applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems such as the insignificant improvement of the edge sealing effect of the adhesive, shorten the drying time, and improve the penetration. Sexuality and adhesion, the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

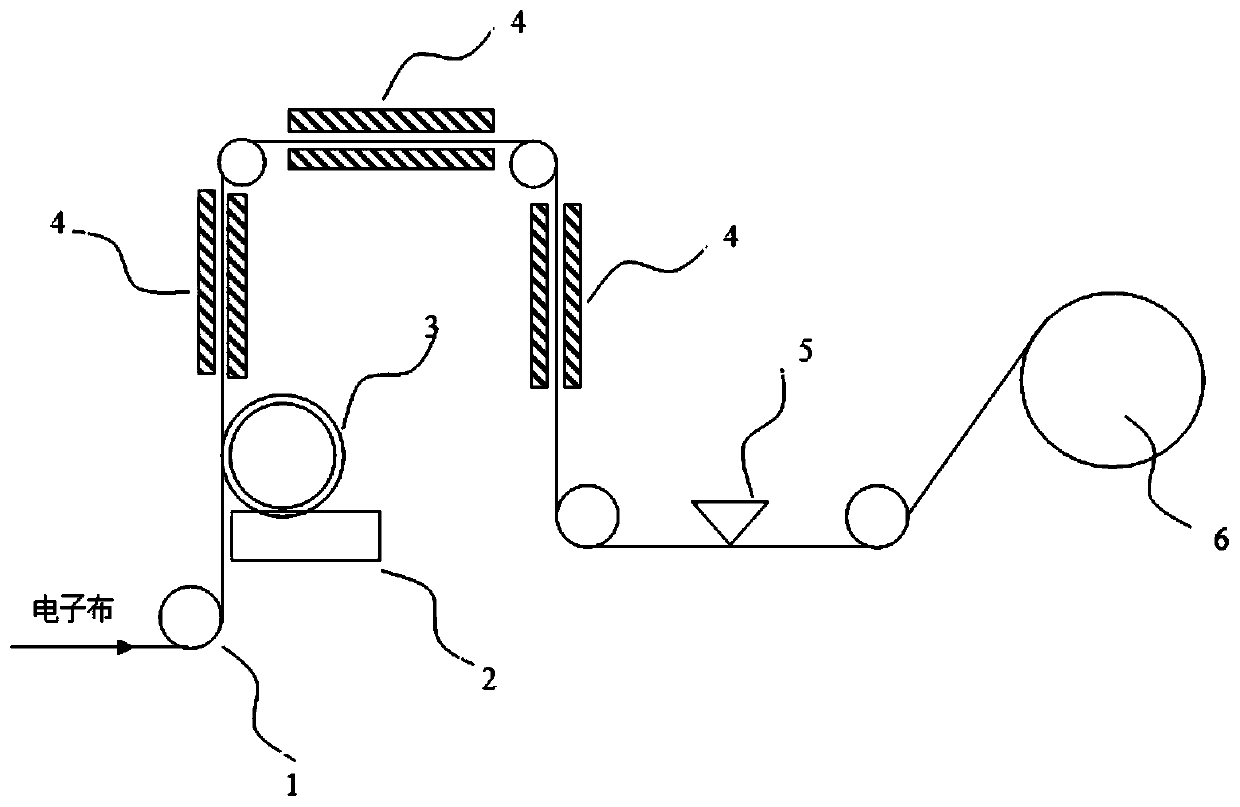

Image

Examples

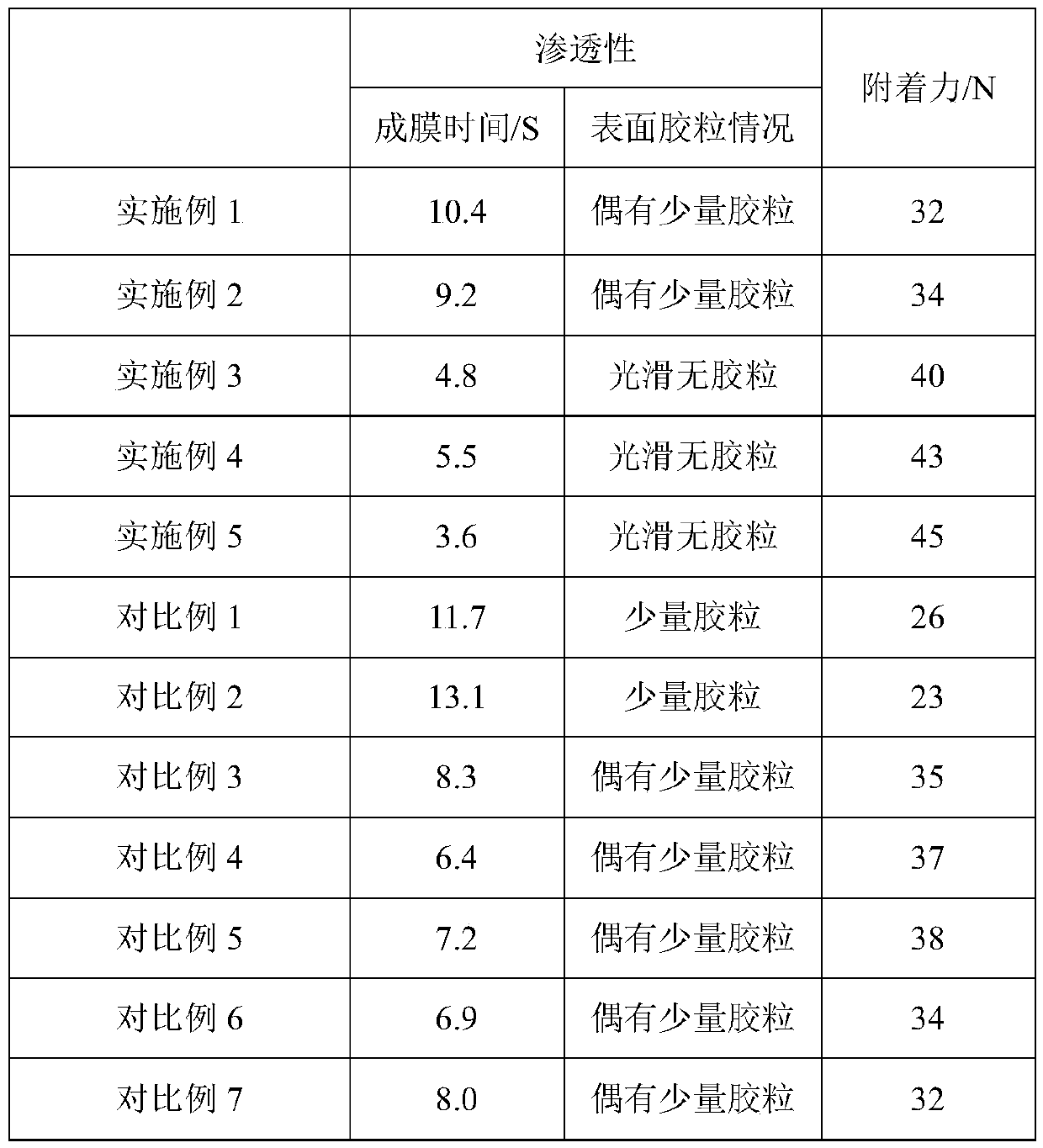

Embodiment 1

[0067] An adhesive composition, comprising the following components in parts by weight: 80 parts of polyether polyurethane, 5 parts of bisphenol A epoxy resin, 0.05 part of polyether modified organosiloxane, and 30 parts of water.

[0068] The preparation method of adhesive composition, comprises the steps:

[0069] (1) Mix and stir polyether polyurethane and part of water in a ratio of 3:1 to obtain substance A, the stirring speed is 40r / min, and the stirring time is 10min;

[0070] (2) Substance A was mixed and stirred with bisphenol A epoxy resin and polyether modified organosiloxane in sequence, the stirring speed was 40r / min, and the stirring time was 10min, to obtain substance B;

[0071] (3) Mix and stir the substance B and the remaining water, the stirring speed is 40r / min, and the stirring time is 10min.

Embodiment 2

[0073] An adhesive composition, comprising the following components in parts by weight: 90 parts of polyester polyurethane, 7 parts of novolac epoxy resin, 0.3 parts of alkyl-modified organosiloxane, and 45 parts of water.

[0074] The preparation method of adhesive composition, comprises the steps:

[0075] (1) Mix and stir polyester polyurethane and part of water according to the ratio of 5:1 to obtain substance A, the stirring speed is 60r / min, and the stirring time is 15min;

[0076] (2) Substance A was mixed and stirred with novolac epoxy resin and alkyl modified organosiloxane in sequence, the stirring speed was 60r / min, and the stirring time was 20min, to obtain substance B;

[0077] (3) Mix and stir the substance B and the remaining water, the stirring speed is 60r / min, and the stirring time is 20min.

Embodiment 3

[0079] An adhesive composition, comprising the following components in parts by weight: 80 parts of polyether polyurethane, 5 parts of bisphenol A epoxy resin, 0.05 part of polyether modified organosiloxane, 30 parts of water, auxiliary 3 doses. The auxiliary agent is a mixture of cellulose acetate butyl ester, nano-sized silicon dioxide, and micron-sized cellulose, and the mass ratio of the three is 1:1.5:3.

[0080] The preparation method of adhesive composition comprises the steps:

[0081] (1) Polyether polyurethane, cellulose acetate butyl ester and part of water are mixed and stirred to obtain material A, the mass ratio of the total mass of the polyether polyurethane and cellulose acetate butyl ester to the part of water is 4:1, stirring Speed 40r / min, stirring time 10min;

[0082] (2) Substance A was mixed and stirred with bisphenol A epoxy resin and polyether modified organosiloxane in sequence, the stirring speed was 40r / min, and the stirring time was 10min, to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com