Sand-containing colored priming paint and preparation method thereof

A coloring and primer technology, applied in the direction of biocide-containing paints, educts, coatings, etc., can solve problems such as insufficient permeability, poor adhesion of the base layer, and many external wall renovation projects, so as to prevent leakage and blooming , Solve the problem of sealing, improve the effect of permeability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment mainly selects fine sand as the main filler in the sand-containing primer.

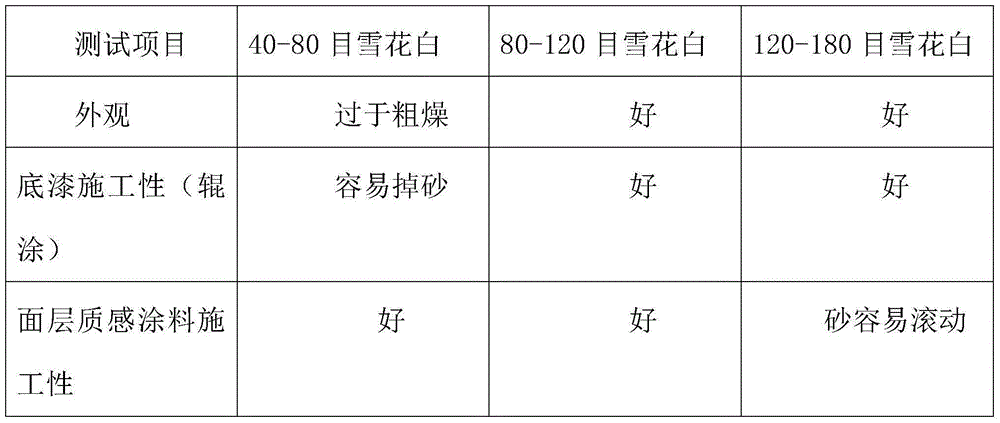

[0032] In order to solve the problem that the surface of the primer film is too smooth, it is necessary to add coarse particle fillers to the formula. In the present invention, 40-80 mesh snowflakes, 80-120 mesh snowflakes, and 120-180 mesh snowflakes are added as fillers to the formula for comparative testing:

[0033] The test results are shown in Table 1.

[0034] Table 1 Contrast test of snowflake white fine sand with different particle sizes as filler

[0035]

[0036] Through the evaluation of the test items shown in Table 1, it is found that snowflake white with a particle size of 80-120 mesh can solve the problem that the textured construction sand of the surface layer is easy to roll, and its own construction performance is good.

Embodiment 2

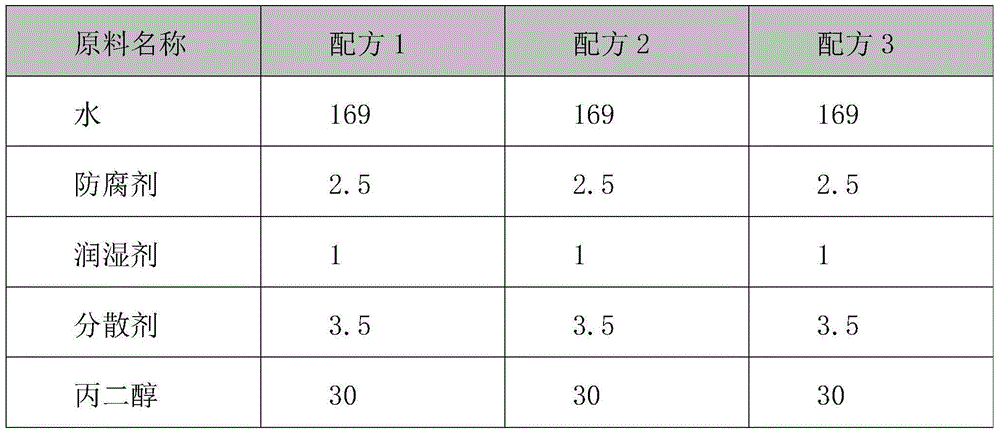

[0038] In order to solve the problem of uneven primer roller coating, the primer must have color. Therefore, when evaluating polymer emulsions, in addition to conventional anti-efflorescence and anti-salting-out properties, it is also necessary to consider its ability to carry pigments and have better color development. The present invention selects 3 commonly used emulsions on the market for evaluation, and the formulations in Table 2 are used for batching when evaluating:

[0039] Table 2 Emulsion Evaluation Formulation

[0040] raw material name

[0041] Test and evaluate the primer paint materials obtained according to the above Table 2. The emulsions are: BASF JC7043, Bardford RS-308, and Polycar BLJ-5531.

[0042] The test results are listed in Table 3:

[0043] Table 3 The test results when three commonly used emulsions are used as the additive components of the primer paint

[0044] Test items

[0045] Alkali resistance

[0046] It ca...

Embodiment 3

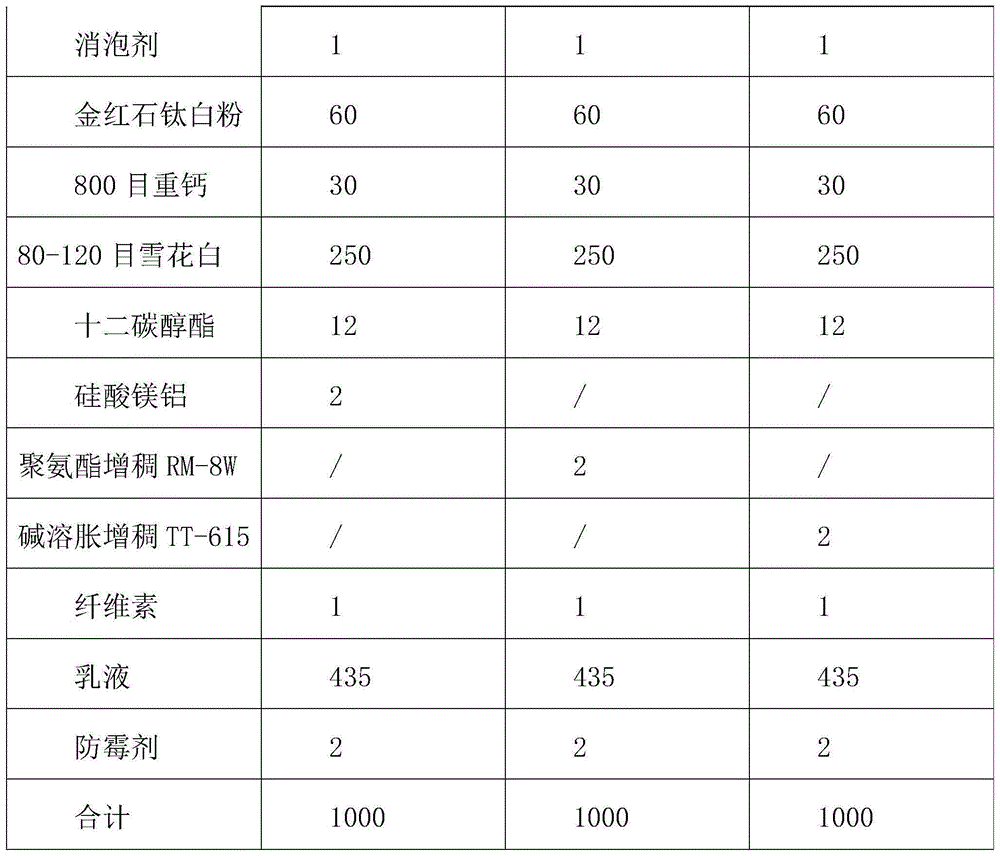

[0048] The primer needs to solve the problem of sealing the pulverized base. It has excellent permeability and can penetrate deep into the pulverized base, so the viscosity should not be too high. However, due to the 80-120 mesh snowflake white sand in the primer, if the viscosity is insufficient, it is easy to cause precipitation. Therefore, the thickening system should take both permeability and anti-sedimentation into account. Based on these two requirements, the present invention selects the following thickening systems with different thickening mechanisms. The test formula is listed in Table 4:

[0049] Table 4 thickening system selection test formula

[0050]

[0051]

[0052] The obtained sand-containing colored primer paint according to the formula of Table 4 is tested, and the test results are shown in Table 5:

[0053] Table 5 Test results of different thickening systems

[0054]

[0055] Among them, the test method for the permeability of powdered base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com