A kind of preparation method of environment-friendly urea-formaldehyde resin adhesive

A urea-formaldehyde resin glue and adhesive technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of large formaldehyde emission, achieve bright color, small formaldehyde emission, Effect of increasing resin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

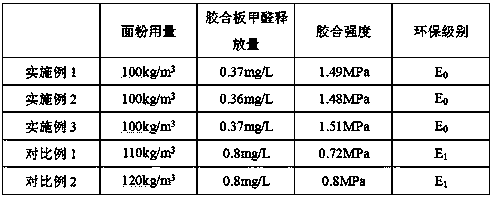

Examples

Embodiment 1

[0020] (1) Prepare materials according to the following components by mass:

[0021] 1700 parts of formaldehyde, 700 parts of urea I, 160 parts of urea II, 270 parts of urea III, 300 parts of urea IV, 70 parts of ammonia water, 3.45 parts of melamine I, 315 parts of melamine II, 15.2 parts of melamine III, 1 part of lye;

[0022] Among them, formaldehyde is a formaldehyde solution with a mass concentration of 37%; ammonia water is an ammonia solution with a mass concentration of 0.8%; urea Ⅰ, urea Ⅱ, urea Ⅲ and urea Ⅳ are all conventional commercially available urea (solid), that is, four parts for preparation , and added in four times; melamine I, melamine II and melamine III are conventional commercially available melamine (solid), that is, prepared in three parts and added in three times; the lye is a sodium hydroxide solution with a mass concentration of 30%;

[0023] (2) Heat the formaldehyde in step (1) to 40°C with stirring, then add 30% sodium hydroxide solution to adj...

Embodiment 2

[0026] (1) Prepare materials according to the following components by mass:

[0027] 1600 parts of formaldehyde, 600 parts of urea I, 120 parts of urea II, 220 parts of urea III, 250 parts of urea IV, 50 parts of ammonia water, 3 parts of melamine I, 300 parts of melamine II, 13 parts of melamine III, 0.9 parts of lye;

[0028] Among them, formaldehyde is a formaldehyde solution with a mass concentration of 30%; ammonia water is an ammonia solution with a mass concentration of 0.5%; urea Ⅰ, urea Ⅱ, urea Ⅲ and urea Ⅳ are all conventional commercially available urea (solid), that is, four parts for preparation , and added in four times; melamine I, melamine II and melamine III are conventional commercially available melamine (solid), that is, prepared in three parts and added in three times; lye is a sodium hydroxide solution with a mass concentration of 25-40% ;

[0029] (2) Heat the formaldehyde in step (1) to 30°C with stirring, then add potassium hydroxide solution with a m...

Embodiment 3

[0032] (1) Prepare materials according to the following components by mass:

[0033] 1800 parts of formaldehyde, 800 parts of urea I, 200 parts of urea II, 300 parts of urea III, 350 parts of urea IV, 80 parts of ammonia water, 4.5 parts of melamine I, 340 parts of melamine II, 18 parts of melamine III, 1.1 parts of lye;

[0034] Among them, formaldehyde is a formaldehyde solution with a mass concentration of 40%; ammonia water is an ammonia solution with a mass concentration of 1%; urea Ⅰ, urea Ⅱ, urea Ⅲ and urea Ⅳ are all conventional commercially available urea (solid), that is, four parts for preparation , and added in four times; melamine I, melamine II and melamine III are conventional commercially available melamine (solid), which are prepared in three parts and added in three times; the lye is a sodium hydroxide solution with a mass concentration of 40%;

[0035](2) Heat the formaldehyde in step (1) to 55°C with stirring, then add sodium hydroxide solution with a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com