Method for curing sludge for landfill

A technology for landfilling garbage and sludge, which is applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc. It can solve the problems of low water content efficiency and difficult resource utilization, and achieve low cost and high treatment efficiency. High, operational control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

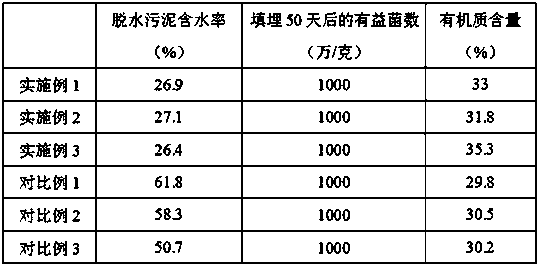

Examples

Embodiment 1

[0020] (1) Based on 100 parts of sludge, prepare materials according to the following components by mass:

[0021] 10 parts of sodium carboxymethyl cellulose Ⅰ, 5 parts of sodium carboxymethyl cellulose Ⅱ, 2 parts of sodium carboxymethyl cellulose Ⅲ, 4 parts of fulvic acid, 8 parts of Bacillus amyloliquefaciens, 4 parts of Lactobacillus acidophilus, 2 parts of peptone, 10 parts of sepiolite powder with a particle size of 150 mesh, and 12 parts of activated carbon with a particle size of 320 mesh;

[0022] (2) Add the sodium carboxymethyl cellulose Ⅰ of step (1) to 100 parts of sludge, keep stirring for 40 minutes, then add fulvic acid and sodium carboxymethyl cellulose II in turn, keep stirring for 40 minutes, then add Bacillus amyloliquefaciens and peptone, continue to feed hot air at 30°C and supply oxygen for 24 hours, stir occasionally during the period, then let it stand and filter, discard the liquid, then add carboxymethylcellulose sodium III to the sludge, and continue...

Embodiment 2

[0025] (1) Based on 100 parts of sludge, prepare materials according to the following components by mass:

[0026] 8 parts of sodium carboxymethyl cellulose Ⅰ, 3 parts of sodium carboxymethyl cellulose Ⅱ, 1 part of sodium carboxymethyl cellulose Ⅲ, 3.5 parts of fulvic acid, 7 parts of Bacillus amyloliquefaciens, 2 parts of Lactobacillus acidophilus, 1.5 parts of peptone, 8 parts of sepiolite powder with a particle size of 100 mesh, and 10 parts of activated carbon with a particle size of 300 mesh;

[0027] (2) Add the sodium carboxymethyl cellulose Ⅰ of step (1) to 100 parts of sludge, keep stirring for 30 minutes, then add fulvic acid and sodium carboxymethyl cellulose II in turn, keep stirring for 30 minutes, then add Bacillus amyloliquefaciens and peptone, continue to feed hot air at 28°C and supply oxygen for 30 hours, stir occasionally during the period, then let it stand and filter, discard the liquid, then add sodium carboxymethylcellulose III to the sludge, and continu...

Embodiment 3

[0030] (1) Based on 100 parts of sludge, prepare materials according to the following components by mass:

[0031] 12 parts of sodium carboxymethyl cellulose Ⅰ, 6 parts of sodium carboxymethyl cellulose Ⅱ, 3 parts of sodium carboxymethyl cellulose Ⅲ, 5 parts of fulvic acid, 10 parts of Bacillus amyloliquefaciens, 6 parts of Lactobacillus acidophilus, 3 parts of peptone, 13 parts of sepiolite powder with a particle size of 200 mesh, and 15 parts of activated carbon with a particle size of 350 mesh;

[0032] (2) Add the sodium carboxymethyl cellulose I of step (1) to 100 parts of sludge, keep stirring for 50 minutes, then add fulvic acid and sodium carboxymethyl cellulose II in turn, keep stirring for 50 minutes, then add Bacillus amyloliquefaciens and peptone, continue to feed hot air at 35°C and supply oxygen for 12 hours, stir occasionally during the period, then let stand and filter, discard the liquid, then add carboxymethylcellulose sodium III to the sludge, and continue s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com