High-performance complex multi-element phosphor bronze alloy material and preparation method thereof

An alloy material, high-performance technology, applied in the field of high-performance complex multi-element phosphor bronze alloy material and its preparation, can solve the problems of high raw material cost, low production efficiency, high price, etc., to reduce production cost, improve production efficiency, reduce The effect of the degree of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

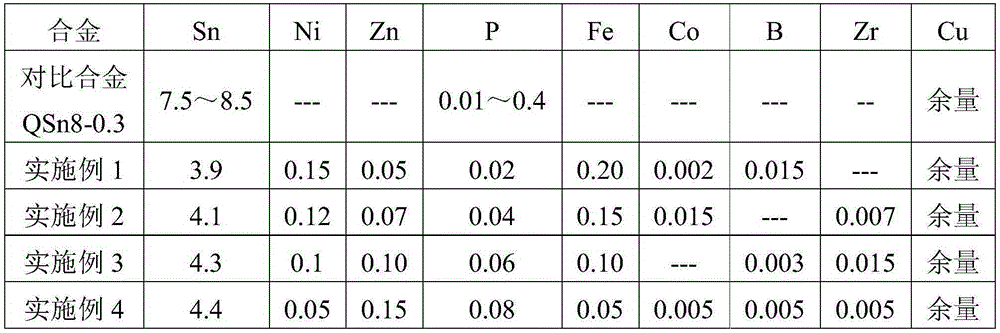

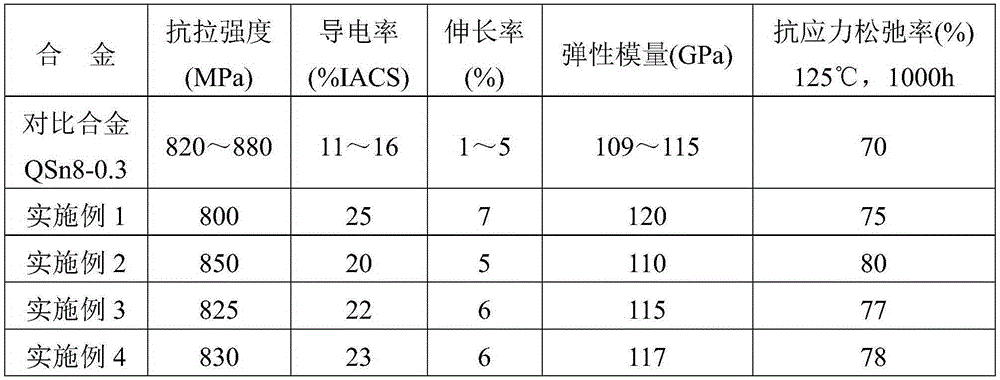

[0030] The alloy of the invention is smelted using the following raw materials: tin phosphor bronze QSn6.5-0.1 scrap, electrolytic copper, electrolytic nickel, electrolytic cobalt, pure zinc, copper boron and copper-iron master alloy. The composition of the alloy is shown in Example 1 of Table 1.

[0031] 1. Smelting: Add 70% tin phosphor bronze QSn6.5-0.1 scrap and 30% new materials into the power frequency induction furnace, among which new materials include electrolytic copper, electrolytic nickel, electrolytic cobalt, pure zinc, copper boron and copper For iron intermediate alloys, raise the temperature to 1260°C. After the electrolytic copper is melted, add burning charcoal to cover it. After fully stirring, let it stand for 15 minutes. When the holding temperature is 1220°C, perform horizontal continuous casting. Casting process parameters It is: pulling speed is 14mm / s, stop for 2.5s, reverse pushing speed is 12mm / s, strip blank outlet temperature is 450℃.

[0032] 2. ...

Embodiment 2

[0040] The alloy of the invention is smelted using the following raw materials: tin phosphor bronze QSn6.5-0.1 scrap, electrolytic copper, electrolytic nickel, electrolytic cobalt, pure zinc, copper iron and copper zirconium master alloy. The composition of the alloy is shown in Example 2 of Table 1.

[0041] 1. Smelting: Add 70% tin phosphor bronze QSn6.5-0.1 scrap and 30% new materials into the power frequency induction furnace, among which new materials include electrolytic copper, electrolytic cobalt, electrolytic nickel, pure zinc, copper iron and copper For zirconium master alloy, raise the temperature to 1280°C. After the electrolytic copper is melted, add burning charcoal to cover it. After fully stirring, let it stand for 25 minutes. When the holding temperature is 1250°C, perform horizontal continuous casting. Casting process parameters It is: pulling speed is 16mm / s, stop for 3.5s, reverse pushing speed is 10mm / s, strip blank outlet temperature is 350℃.

[0042] 2....

Embodiment 3

[0050] The alloy of the invention is smelted using the following raw materials: tin phosphor bronze QSn6.5-0.1 scrap, electrolytic copper, electrolytic nickel, pure zinc, copper boron, copper iron and copper zirconium master alloy. The composition of the alloy is shown in Example 3 of Table 1.

[0051] 1. Melting: Add 70% tin phosphor bronze QSn6.5-0.1 scrap and 30% new materials into the power frequency induction furnace, among which new materials include electrolytic copper, electrolytic nickel, pure zinc, copper boron, copper iron and copper For zirconium master alloy, raise the temperature to 1300°C. After the electrolytic copper is melted, add burning charcoal to cover it. After fully stirring, let it stand for 20 minutes. When the holding temperature is 1230°C, perform horizontal continuous casting. Casting process parameters It is: pulling speed is 15mm / s, stop for 3s, reverse pushing speed is 11mm / s, strip blank outlet temperature is 400℃.

[0052] 2. Rough rolling: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com