Copper alloy with softening resistance and preparation method and application thereof

A copper alloy, anti-softening technology, used in metal/alloy conductors, conductive materials, conductive materials, etc., can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

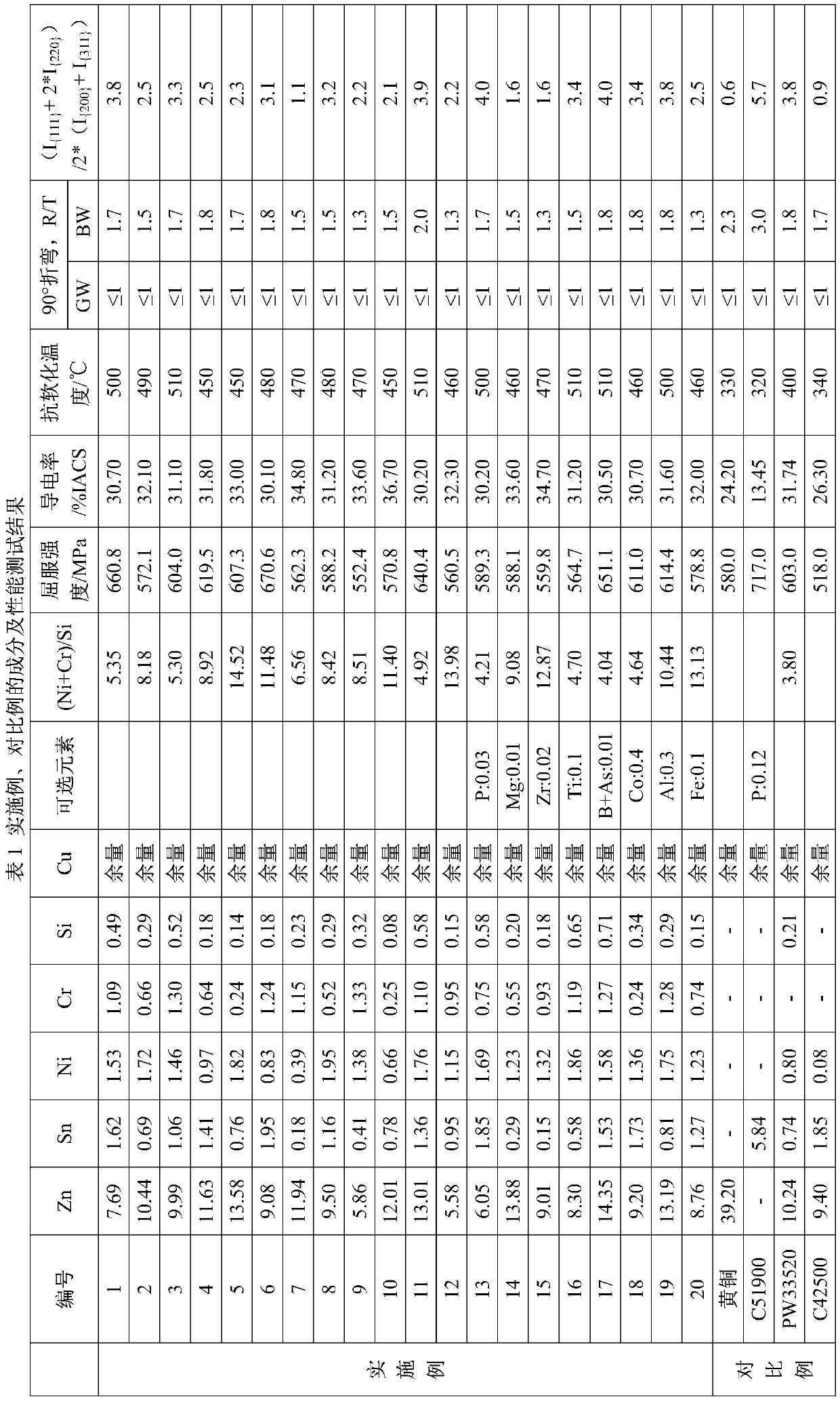

[0036] Below in conjunction with embodiment the present invention is described in further detail.

[0037] According to the composition in Table 1, the copper alloy of the composition combination shown in Table 1 was melted at 1150° C., and an ingot having a specification of 170 mm×320 mm was produced. After the above-mentioned ingot was kept at 800°C for 5 hours, it was hot-rolled to a thickness of 16.5mm. After the hot-rolling was completed, it was cooled with water online; then, the surface was milled to a thickness of 15mm, and then cold-rolled to a thickness of 2mm. Then heat the cold-rolled plate to 440°C, keep it warm for 8h, and carry out the first aging; carry out the second cold-rolling of the aged material, cold-rolled to 0.4mm, and then hold it at 400°C for 8h The second aging treatment; finally, the finish cold rolling is carried out, and the rolling target plate thickness is 0.3 mm; after the finish cold rolling, it is kept at 210° C. for 4 hours for low-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com