High-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics and preparation method thereof

A potassium-sodium niobate-based, lead-free piezoelectric technology, applied in the field of high-voltage potassium-sodium niobate-based lead-free piezoelectric ceramics and its preparation, can solve problems such as high-voltage performance, difficulty in obtaining, and complex process , to achieve the effect of increasing the piezoelectric coefficient, shortening the time, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

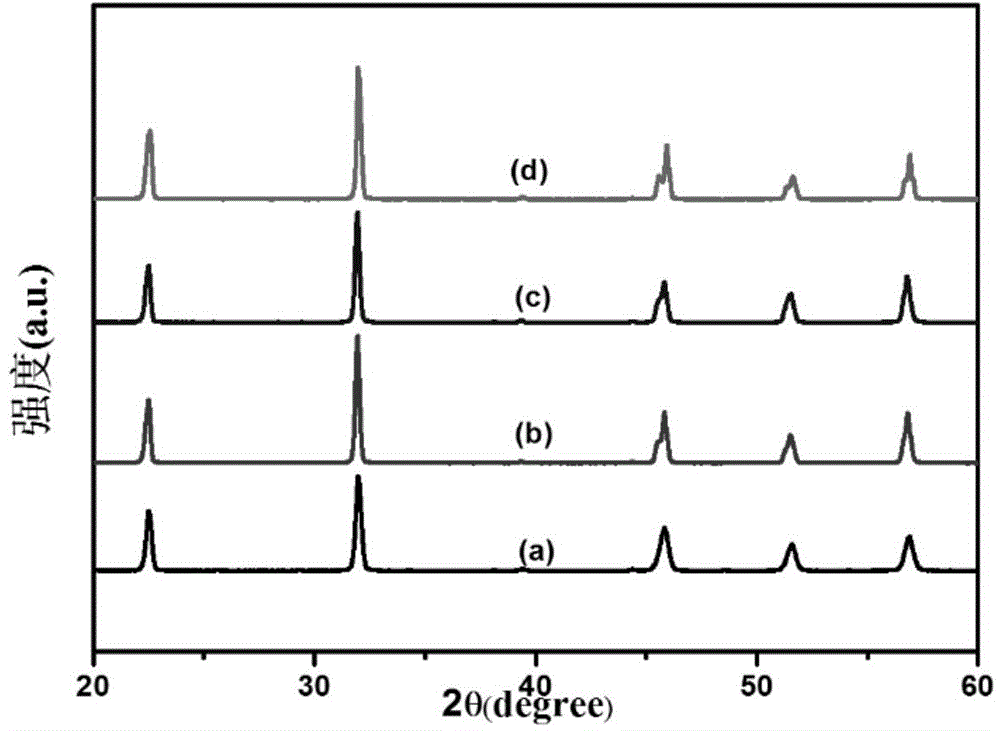

[0033] (1) According to (1-a) (K 0.5 Na 0.5 ) 0.95 Li 0.05 Nb 0.93 Sb 0.07 -aCaZrO 3 The stoichiometric ratio of raw material Na 2 CO 3 , K 2 CO 3 , Li 2 CO 3 ,Nb 2 o 5 ,Sb 2 o 5 and CaCO 3 , where a=0.04, put into the ball mill tank and carry out mixing, the ball milling medium is absolute ethanol and zirconia balls, the mass ratio of mixed raw materials and zirconia balls is 1:1.2, and the mass ratio with absolute ethanol is 1: 1.5; The mixed raw materials are ball milled at a speed of 360r / min for 24h, dried at 100°C, put into a corundum crucible, covered, and kept at 850°C for 6h, with a heating rate of 3°C / min;

[0034](2) Grind the powder obtained in step (1) in a mortar, carry out secondary ball milling, the conditions of ball milling and drying are the same as in step (1), and obtain 0.96 (K 0.5 Na 0.5 ) 0.95 Li 0.05 Nb 0.93 Sb 0.07 -0.04CaZrO 3 mixed powder;

[0035] (3) The powder material that step (2) obtains is added the PVA solution that c...

Embodiment 2

[0040] (1) According to (1-a) (K 0.5 Na 0.5 ) 0.95 Li 0.05 Nb 0.93 Sb 0.07 -aCaZrO 3 The stoichiometric ratio of raw material Na 2 CO 3 ,K 2 CO 3 , Li 2 CO 3 ,Nb 2 o 5 ,Sb 2 o 5 and CaCO 3 , wherein a=0.04, put into the ball mill tank and carry out mixing, the ball milling medium is absolute ethanol and zirconia balls, the mass ratio of mixed raw materials and zirconia balls is 1:1.2, and the mass ratio with absolute ethanol is 1: 1.5; The mixed raw materials are ball milled at a speed of 360r / min for 24h, dried at 100°C, put into a corundum crucible, covered, and kept at 850°C for 6h, with a heating rate of 3°C / min;

[0041] (2) Grind the powder obtained in step (1) in a mortar, carry out secondary ball milling, the conditions of ball milling and drying are the same as in step (1), and obtain 0.96 (K 0.5 Na 0.5 ) 0.95 Li 0.05 Nb 0.93 Sb 0.07 -0.04CaZrO 3 mixed powder;

[0042] (3) The powder material that step (2) obtains is added the PVA solution that...

Embodiment 3

[0047] (1) According to (1-a) (K 0.5 Na 0.5 ) 0.95 Li 0.05 Nb 0.93 Sb 0.07 -aCaZrO 3 The stoichiometric ratio of raw material Na 2 CO 3 ,K 2 CO 3 , Li 2 CO 3 ,Nb 2 o 5 ,Sb 2 o 5 and CaCO 3 , wherein a=0.04, put into the ball mill tank and carry out mixing, the ball milling medium is absolute ethanol and zirconia balls, the mass ratio of mixed raw materials and zirconia balls is 1:1.2, and the mass ratio with absolute ethanol is 1: 1.5; The mixed raw materials are ball milled at a speed of 360r / min for 24h, dried at 100°C, put into a corundum crucible, covered, and kept at 850°C for 6h, with a heating rate of 3°C / min;

[0048] (2) Grind the powder obtained in step (1) in a mortar, carry out secondary ball milling, the conditions of ball milling and drying are the same as in step (1), and obtain 0.96 (K 0.5 Na 0.5 ) 0.95 Li 0.05 Nb 0.93 Sb 0.07 -0.04CaZrO 3 mixed powder;

[0049] (3) The powder material that step (2) obtains is added the PVA solution that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com