Preparation method of (K05Na05) NbO3 (KNN) lead-free piezoelectric ceramic material

A technology of potassium sodium niobate and ceramic materials, which is applied in the field of lead-free piezoelectric materials, can solve the problems of high price, increased material preparation cost, unfavorable industrial production, etc., achieves simple methods, promotes application progress, and improves sinterability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

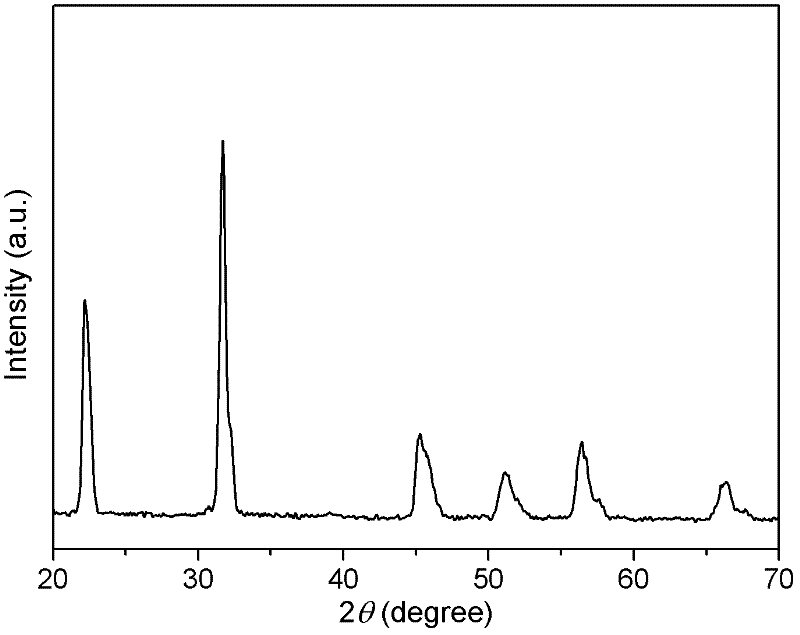

[0045] Preparation of potassium sodium niobate ceramic material a by high energy ball milling.

[0046] According to (K x Na 1-x )NbO 3 (x=0.50) formula, weigh 2.094g K respectively with electronic balance 2 CO 3 Powder, 1.590g Na 2 CO 3 powder, and 7.982g Nb 2 o 5 For powder, mix the raw materials evenly, burn at 200°C, place it in a high-energy ball mill for 24 hours, then heat the obtained powder at 650°C for 4 hours to obtain potassium sodium niobate powder, and then dissolve the obtained powder with absolute ethanol As the medium, mix the powder with a planetary ball mill for 24 hours, dry the slurry at 80°C, add 8wt% PVA to the powder as a binder to granulate, dry press, hold at 550°C for 6h to remove the viscosity, and obtain potassium sodium niobate. Blank, put the formed green blank into a programmed temperature-controlled box furnace for sintering, the sintering temperature is 1130°C, and the holding time is 3h. The obtained ceramic original sheet is polished...

Embodiment 2

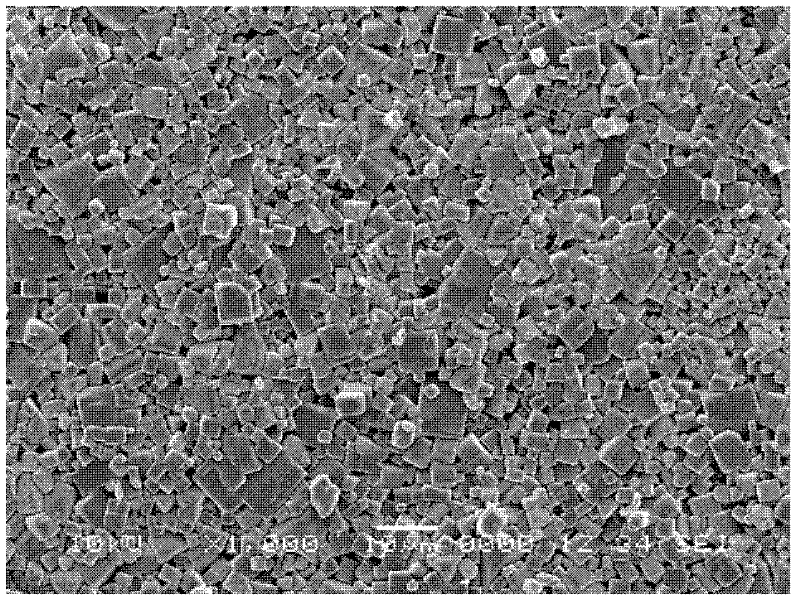

[0050] Potassium sodium niobate ceramic material b prepared by high energy ball milling.

[0051] According to (K x Na 1-x )NbO 3 (x=0.50) formula, weigh 2.094g K respectively with electronic balance 2 CO 3 Powder, 1.590g Na 2 CO 3 powder, and 7.982g Nb 2 o 5 For the powder, use absolute ethanol as the medium, mix the powder with a planetary ball mill for 24 hours, dry the slurry at 80°C, and then heat the obtained dry powder at 850°C for 4 hours to synthesize potassium sodium niobate. The synthesized powder was high-energy ball milled for 24 hours, and then the obtained powder was granulated by adding 8wt% PVA as a binder, dry-pressed, and kept at 550°C for 6 hours to remove stickiness to obtain a green body of potassium sodium niobate. The green body was sintered in a programmable temperature-controlled box-type furnace at a temperature of 1130°C and a holding time of 3 hours. The obtained ceramic original sheet was polished with fine sand, coated with silver paste o...

Embodiment 3

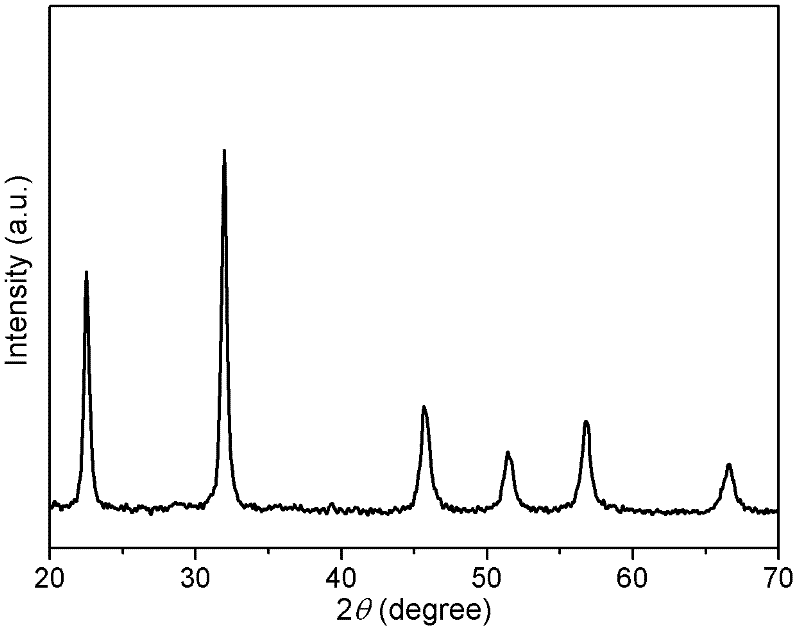

[0054] Preparation of potassium sodium niobate ceramic material a by high energy ball milling.

[0055] According to (K x Na 1-x )NbO 3 (x=0.50) formula, weigh 2.094g K respectively with electronic balance 2 CO 3 Powder, 1.590g Na 2 CO 3 powder, and 7.982g Nb 2 o 5 For powder, mix the raw materials evenly, burn at 200°C, place it in a high-energy ball mill for 32 hours, then heat the obtained powder at 500°C for 2 hours to obtain potassium sodium niobate powder, and then dissolve the obtained powder with absolute ethanol As the medium, mix the powder with a planetary ball mill for 24 hours, dry the slurry at 80°C, add 8wt% PVA to the powder as a binder to granulate, dry press, hold at 550°C for 6h to remove the viscosity, and obtain potassium sodium niobate. Blank, put the formed green blank into a programmed temperature-controlled box furnace for sintering, the sintering temperature is 1130°C, and the holding time is 3h. The obtained ceramic original sheet is polished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com