Method for preparing potassium sodium niobate base leadless piezoelectric ceramic

A potassium sodium niobate-based, lead-free piezoelectric technology, applied in the field of functional materials, can solve problems such as few reports, and achieve the effect of simple and easy preparation process, excellent piezoelectric and ferroelectric properties, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Na with a purity of 99.8% 2 CO 3 , a purity of 99.5% K 2 CO 3 , a purity of 99.5% Li 2 CO 3 , Nb with a purity of 99.9% 2 o 5 , according to the chemical formula (Li 0.06 Na 0.52 K 0.42 )NbO 3For batching, use a planetary ball mill to mix and ball mill for 10 hours at a speed of 100 rpm, and pre-fire at 700°C for 6 hours to synthesize ceramic powder. Sintering with two-step sintering process: heat up to 850°C at 30°C / min, then heat up to 1050°C at 10°C / min, hold for 2 minutes, then drop to 950°C at 20°C / min, hold for 10 hours, and then cool to room temperature .

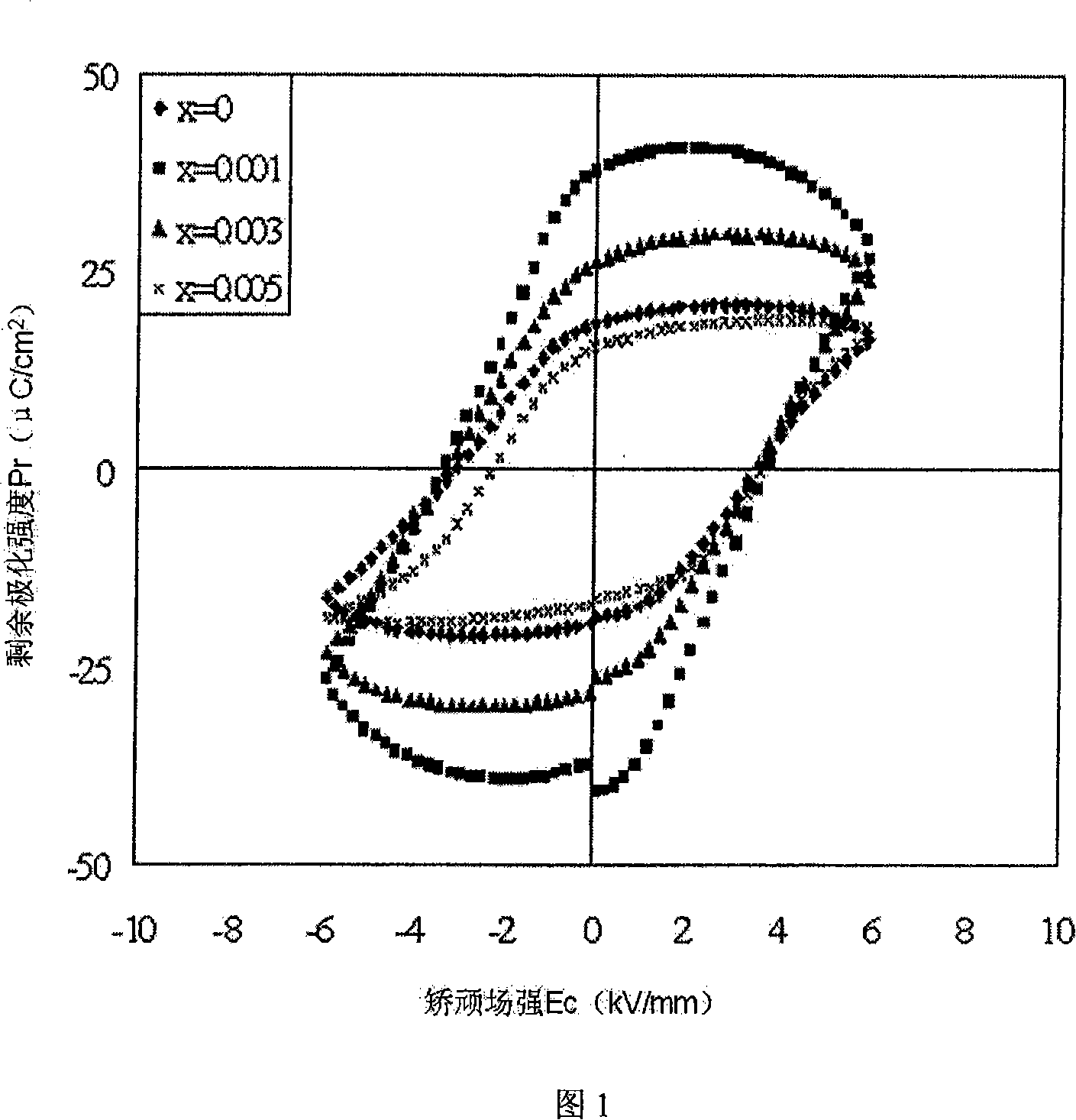

[0035] Compared with the traditional method, the electrical properties of the prepared niobate-based lead-free piezoelectric ceramics are:

[0036] d 33 (pC / N)

Embodiment 2

[0038] Na with a purity of 99.8% 2 CO 3 , a purity of 99.5% K 2 CO 3 , a purity of 99.5% Li 2 CO 3 , Nb with a purity of 99.9% 2 o 5 , MgO with a purity of 98% according to the chemical formula 0.99(Li 0.06 Na 0.52 K 0.42 )NbO 3 +0.01MgO for batching, mixed and ball milled for 3 hours with a planetary ball mill at a speed of 450rpm, and pre-fired at 800°C for 3 hours to synthesize ceramic powder. Sintering with two-step sintering process: heat up to 900°C at 30°C / min, then rise to 1100°C at 10°C / min, hold for 5 minutes, then drop to 1000°C at 20°C / min, hold for 15 hours, and then cool to room temperature .

[0039] Compared with the traditional method, the electrical properties of the prepared niobate-based lead-free piezoelectric ceramics are:

[0040] d 33 (pC / N)

Embodiment 3

[0042] Na with a purity of 99.8% 2 CO 3 , a purity of 99.5% K 2 CO 3 , a purity of 99.5% Li 2 CO 3 , Nb with a purity of 99.9% 2 o 5 , MgO with a purity of 98% according to the chemical formula 0.95(Li 0.06 Na 0.52 K 0.42 )NbO 3 +0.05MgO for batching, mixed and ball milled with a planetary ball mill for 7 hours at a speed of 350rpm, and pre-fired at 750°C for 4 hours to synthesize ceramic powder. Sintering with two-step sintering process: heating up to 950°C at 30°C / min, then rising to 1150°C at 10°C / min, holding for 10 minutes, then lowering to 1050°C at 20°C / min, holding for 18 hours, and then cooling to room temperature .

[0043] Compared with the traditional method, the electrical properties of the prepared niobate-based lead-free piezoelectric ceramics are:

[0044] d 33 (pC / N)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com