Modified PZT piezoelectric ceramics with Nano powder being added directly, and preparation method

A technology of nano-powder and piezoelectric ceramics, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of high cost of finished products and low application value, and achieve electromechanical coupling coefficient Low, reproducible, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

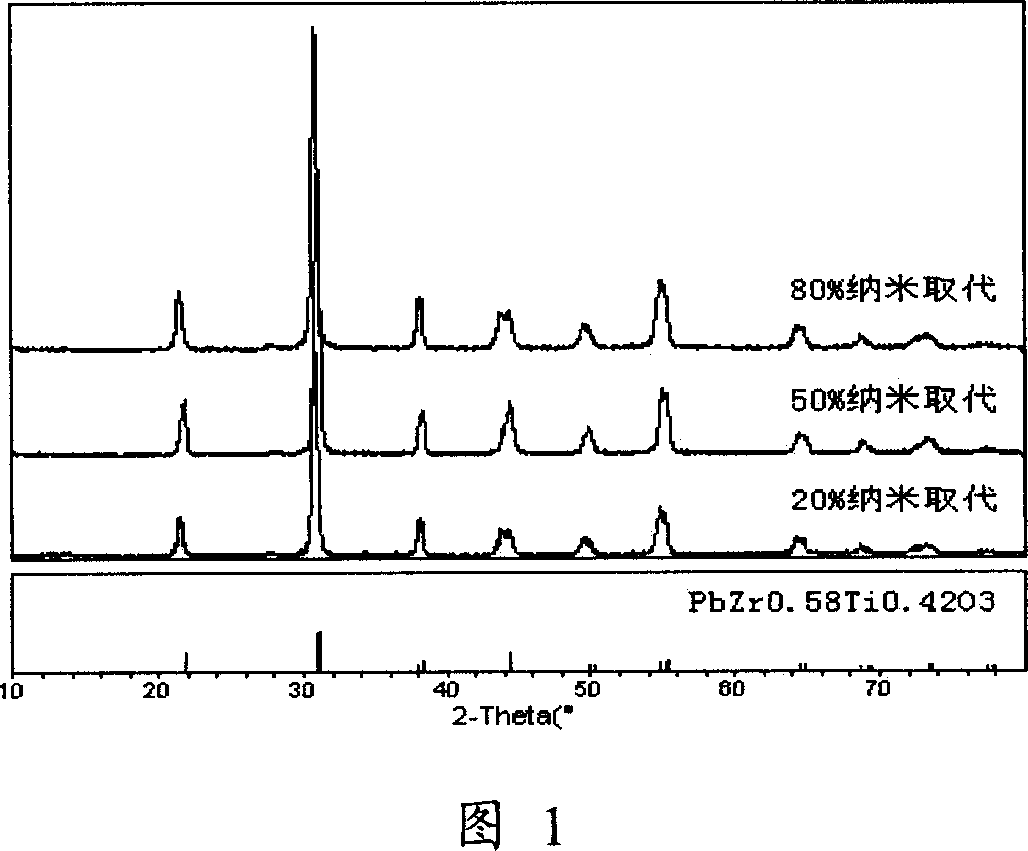

[0023] According to formula Pb 1-X A X (Zr 0.5+Y Ti 0.4+Z )(B 1 / 3 C 2 / 3 ) Y+Z o 3 , wherein A is Mg, B is Mn, and C is Nb; x=0.10, Y=0.026, Z=0.074. Mole ratio Pb 3 o 4 : Micron (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O: ZrO 2 :( Micron TiO 2 : Nano TiO 2 ): MnCO 3 : Nb 2 o 5 =0.3000: 0.02: 0.5260: (0.2844: 0.1896): 0.0333: 0.0333 Weighing, preparation conforms to the composition of the formula and includes the mixture of nano-powder component additives; the weight ratio of the mixture to deionized water is 2: 1.0 Add deionized water and mix with rolling ball mill at 300r / min for 36h; dry the ball mill at 180°C for 24h; put the dried mixture into an alumina crucible and calcinate at 890°C for 2h to synthesize the PZT phase as the main crystal phase, containing a small amount of PbZrO 3 and PbTiO 3 Crystalline nanopowder is added to calcined material. Add deionized water to the calcined material according to the weight ratio of calcined material and deionized water as...

Embodiment 2

[0025] According to formula Pb 1-X A X (Zr 0.5+Y Ti 0.4+Z )(B 1 / 3 C 2 / 3 ) Y+Z o 3 , wherein A is Mg, B is Mn, and C is Nb; x=0.10, Y=0.026, Z=0.074. Mole ratio Pb 3 o 4 : Micron (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O: ZrO 2 :( Micron TiO 2 : Nano TiO 2 ): MnCO 3 : Nb 2 o 5 =0.3000: 0.02: 0.5260: (0.1896: 0.2844): 0.0333: 0.0333 Weighing, preparation conforms to the composition of the formula and includes the mixture of nano-powder component additives; the weight ratio of the mixture to deionized water is 2: 1.0 Add deionized water, mix at a speed of 300r / min for 36 hours; dry the ball mill at 180°C for 24 hours; put the dried mixture into an alumina crucible, and calcinate it at 845°C for 5 hours to synthesize the PZT phase as the main crystal phase, containing a small amount of PbZrO 3 and PbTiO 3 Crystalline nanopowder is added to calcined material. Add deionized water to the calcined material according to the weight ratio of calcined material and deionized wate...

Embodiment 3

[0027] According to formula Pb 1-X A X (Zr 0.5+Y Ti 0.4+Z )(B 1 / 3 C 2 / 3 ) Y+Z o 3 , wherein A is Mg, B is Mn, and C is Nb; x=0.10, Y=0.026, Z=0.074. Mole ratio Pb 3 o 4 : Micron (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O: ZrO 2 :( Micron TiO 2 : Nano TiO 2 ): MnCO 3 : Nb 2 o 5 =0.3000: 0.02: 0.5260: (0.0948: 0.3792): 0.0333: 0.0333 Weighing, preparation conforms to the composition of the formula and includes the mixture of nano-powder component additives; the weight ratio of the mixture to deionized water is 2: 1.0 Add deionized water, mix with rolling ball mill at a speed of 300r / min for 36h; dry the ball mill at 180°C for 24h; put the dried mixture into an alumina crucible, and calcinate at 800°C for 10h to synthesize the PZT phase as the main crystal phase, containing a small amount of PbZrO 3 and PbTiO 3 Crystalline nanopowder is added to calcined material. Add deionized water to the calcined material according to the weight ratio of calcined material and deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com