Bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic and preparation method thereof

A technology of composite perovskite and piezoelectric ceramics, which is applied in the field of bismuth-containing composite perovskite-lead zirconate titanate quasi-ternary piezoelectric ceramics and its preparation, and can solve the problem of no bismuth-containing composite perovskite and piezoelectric ceramics. The electrical properties and preparation process of lead zirconate titanate solid solution piezoelectric ceramics can achieve good piezoelectric and electromechanical coupling properties, reduce lead volatilization loss, and reduce sintering temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The specific steps of the preparation method are:

[0043] 1. Take K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 、 Bi 2 o 3 , Pb 3 o 4 , Nb 2 o 5 、WO 3 , ZrO 2 、TiO 2 , MgO, ZnO, NiO, CoO, and metal oxides or carbonates for doping as raw materials, according to formula (1) ingredients;

[0044] 2. The prepared raw materials are mixed with absolute ethanol for 6-12 hours and dried to obtain dry powder; the obtained dry powder is calcined in an alumina crucible at a temperature of 800-1000°C for 1-4 hours; repeated ball milling The mixing and calcination process is done once to complete the pre-calcination synthesis;

[0045] 3. After the pre-synthesized powder is ground, it is still finely ground for 18-24 hours with absolute ethanol as the medium. After the dried powder is passed through a 110-130 mesh sieve, it is formed into a green body under a pressure of 50-200 MPa;

[0046] 4. The formed green body is sintered in the air under normal pressure using the buried p...

Embodiment 1

[0052] Carry out each step successively according to above-mentioned embodiment mode, wherein,

[0053] Using (1-n)[(1-u)Pb(Zr 0.56 Ti 0.44 )O 3 +uBi(Zn 0.5 Ti 0.5 )O 3 ] + nCuO is composed of piezoelectric ceramics, the pre-calcination temperature is 900 ℃, and the time is 4 hours. After two calcinations, ball mill again for 24 hours with absolute ethanol as the ball milling medium. The post-formed green body is then sintered in the range of 950-1150° C. for 2 hours.

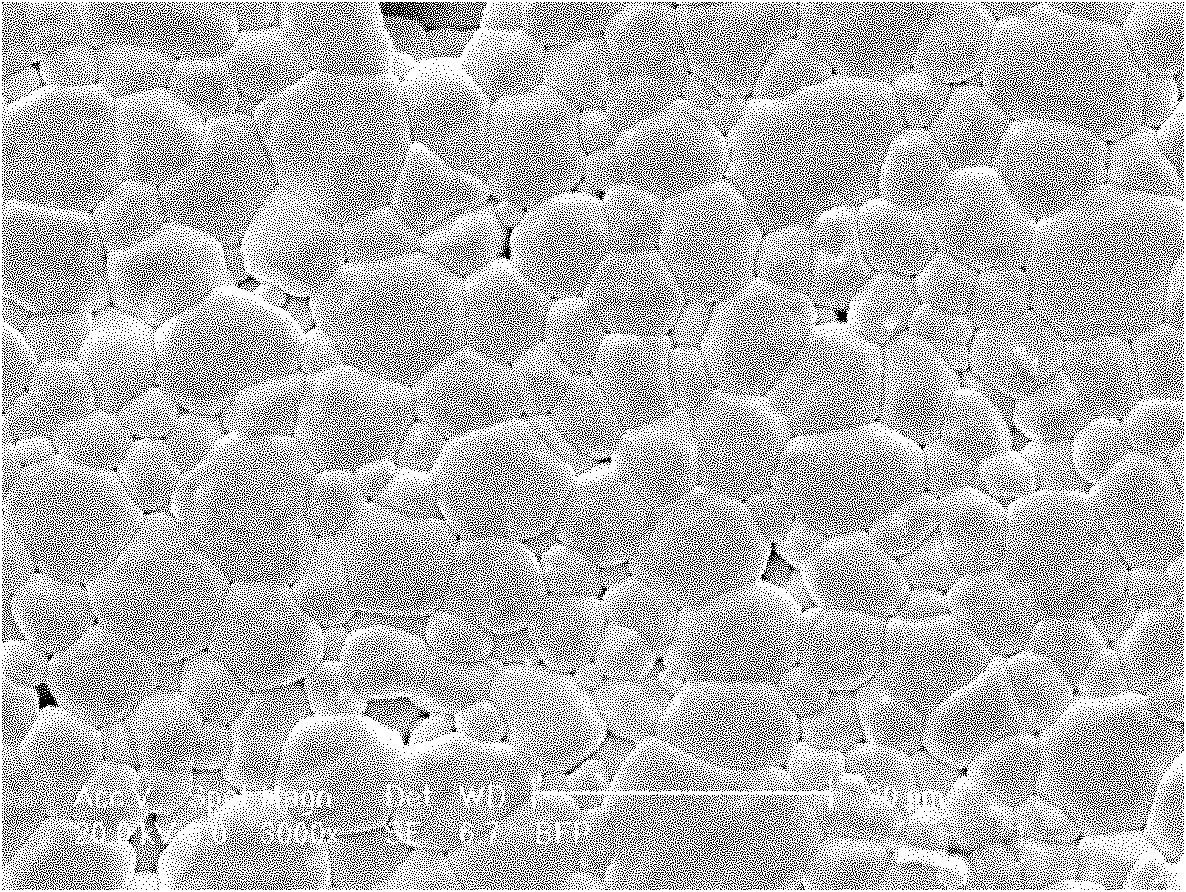

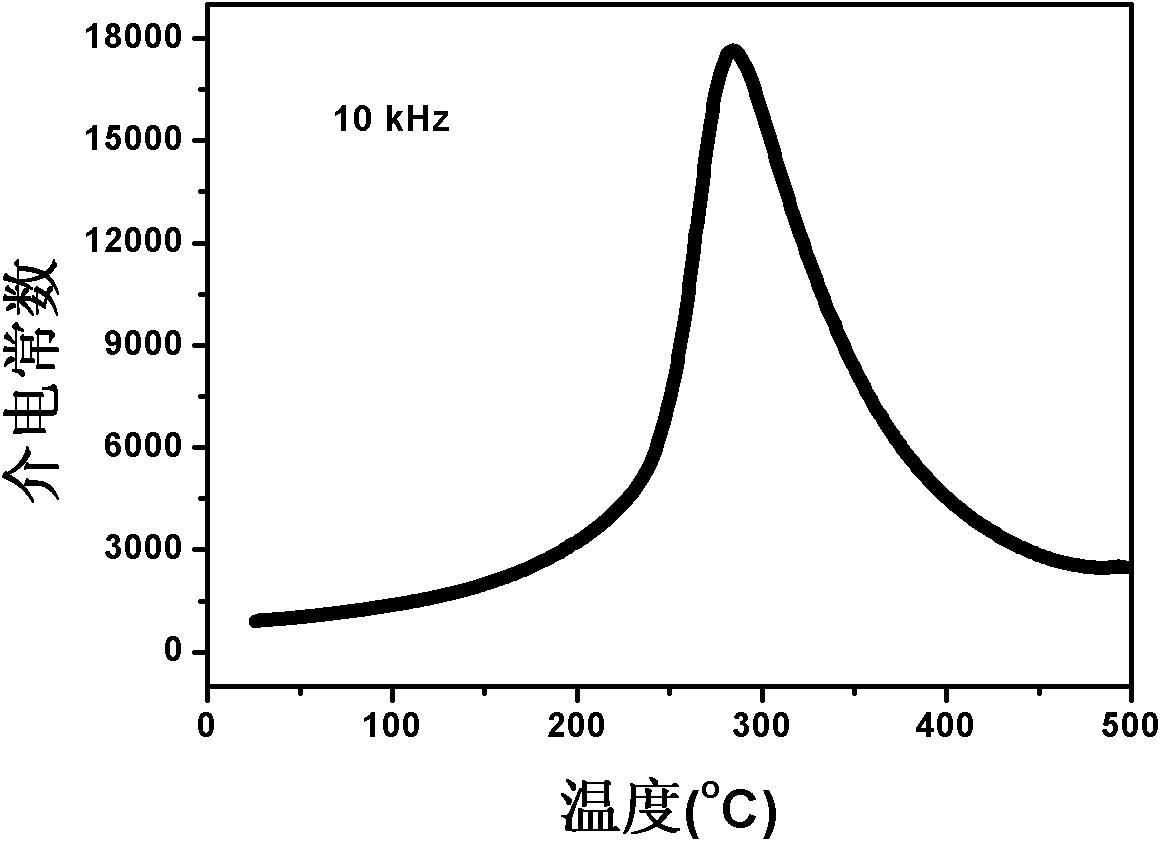

[0054] When u=0.15, n=0, the scanning electron micrograph of the natural surface of the sample after sintering at 1050°C for 2 hours is as follows figure 1 As shown, its dielectric-temperature characteristic curve is as follows figure 2 .

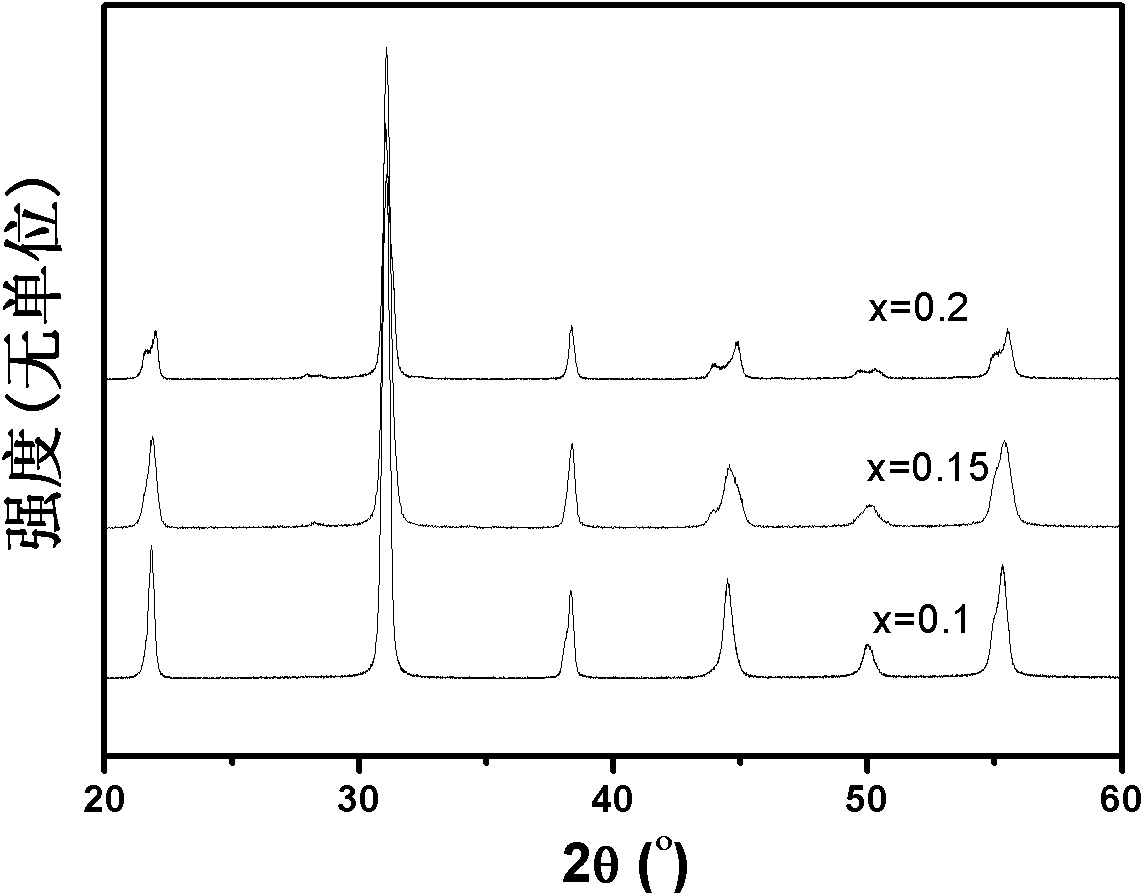

[0055] When n=0.005, u=0.1, 0.15 and 0.2, the X-ray diffraction pattern of the composition sample is as image 3 shown.

[0056] When n=0.005, u=0.15, the hysteresis loop of the composition sample after sintering at 1050°C is as follows Figure 4 shown.

[0057...

Embodiment 2

[0059] Carry out each step successively according to above-mentioned embodiment mode, wherein

[0060] Using ((1-n)[(1-v)Pb(Zr 0.5 Ti 0.5 )O 3 +v(Bi 0.5 (Na 0.32 K 0.63 Li 0.05 ) 0.5 )TiO 3 ]+nMnO 2 When v=0.15 and n=0.005, the pre-calcination temperature is 850° C. and the time is 4 hours. After two calcinations, ball mill again for 20 hours with absolute ethanol as the ball milling medium. Then the electric hysteresis loop after sintering at 1050°C for 2 hours is as follows: Figure 5 shown.

[0061] When v=0.15, n=0, after the sample was sintered at 1050°C for 2 hours, other physical properties of the sample were measured: the Curie temperature was 310°C, the dielectric constant was 1020 (1kHz), and the piezoelectric constant was 462pC / N, the planar electromechanical coupling coefficient is 63%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com