Lead-free piezoelectric film material and preparation method thereof

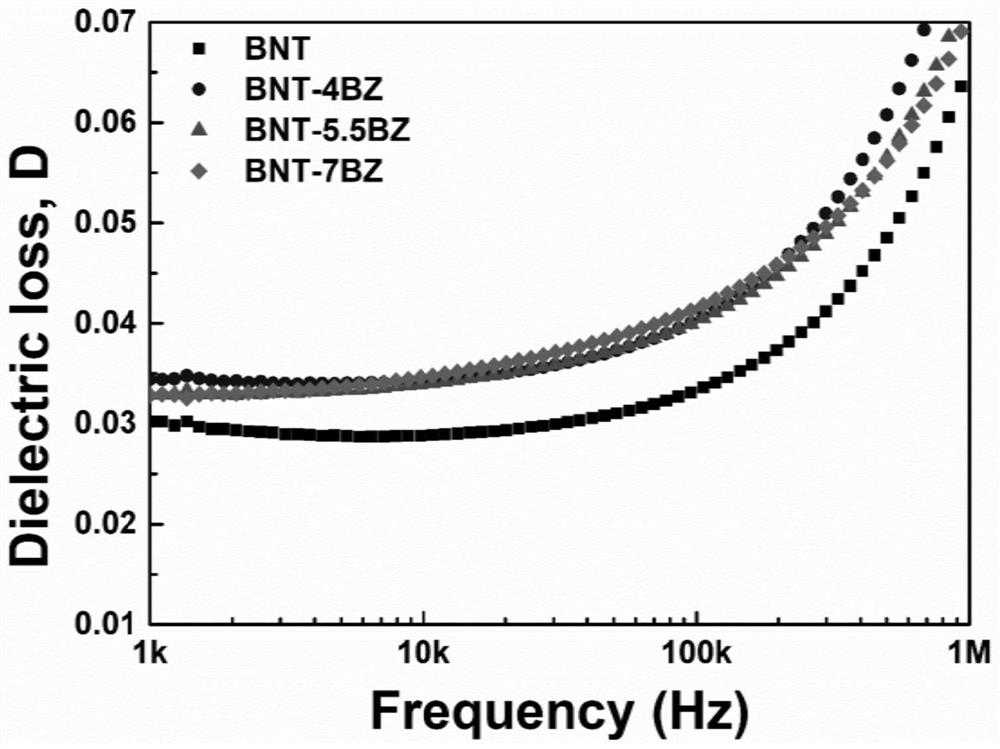

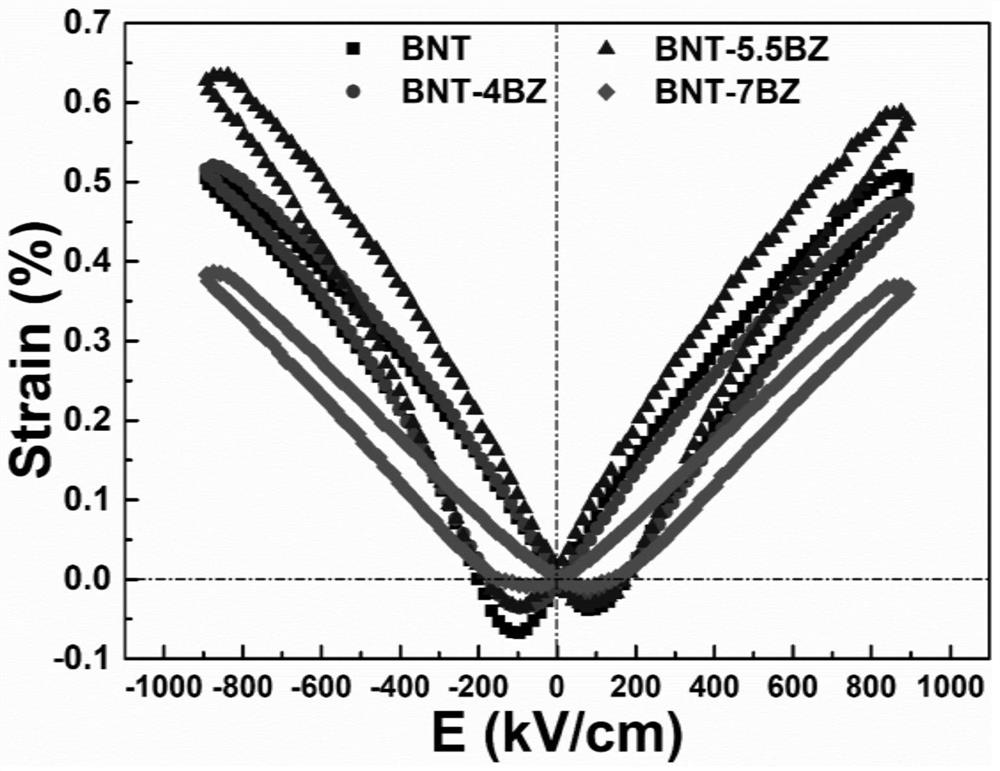

A thin-film material and lead-free piezoelectric technology, applied in the field of lead-free piezoelectric thin-film materials and their preparation, can solve the problems of low strain and low piezoelectric performance of lead-free piezoelectric thin-film materials, and reduce loss and leakage current, dielectric The effect of reducing electrical loss and reducing oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a lead-free piezoelectric thin film material, which is prepared by a sol-gel method, specifically comprising the following steps:

[0036] Step 1. Select bismuth acetate, sodium acetate, tetrabutyl titanate, barium acetate and tetrabutyl zirconate as raw materials to prepare BNT-xBZ precursor solution; wherein, the concentration of BNT-xBZ precursor solution 0.3-0.4mol / L, the volume of the prepared solution is 30-40mL; due to the annealing process, the alkali elements Bi and Na are easy to volatilize, therefore, when weighing the raw materials, provide the acetic acid by an excess of 2%-5%. For bismuth, the sodium acetate is provided in excess of 5%-15%.

[0037] The preparation process of BNT-xBZ precursor solution is as follows:

[0038] First, measure 10-15mL of ethylene glycol methyl ether; then, weigh bismuth acetate, sodium acetate and barium acetate respectively; finally measure 10-15mL of acetic acid, h...

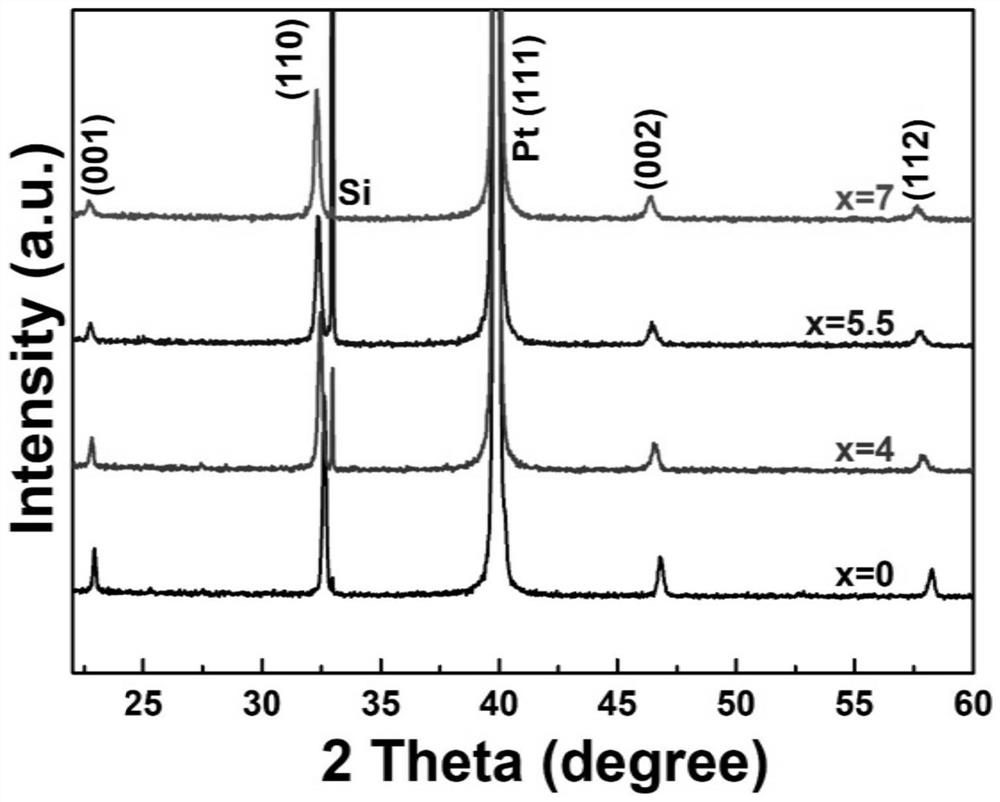

Embodiment 1

[0047] This embodiment 1 provides a lead-free piezoelectric thin film material, and the general chemical formula of the components of the lead-free piezoelectric thin film material is: (1-x)(Bi 0.5 Na 0.5 )TiO 3 -x%BaZrO 3 , where x=0.

[0048] The preparation method of the lead-free piezoelectric thin film material in Embodiment 1 specifically includes the following steps:

[0049] Step 1. Select the raw materials of bismuth acetate, sodium acetate, tetrabutyl titanate, barium acetate and tetrabutyl zirconate of analytical purity or above to prepare the BNT-0BZ precursor solution. The concentration of the precursor solution is 0.3mol / L. The volume of the solution is 30 mL; since the alkali metal elements Bi and Na are easily volatile during annealing, when bismuth acetate and sodium acetate are weighed, bismuth acetate is provided in excess of 2%, and sodium acetate is provided in excess of 5%.

[0050] Preparation process:

[0051] First, measure 10 mL of ethylene glyco...

Embodiment 2

[0062] This embodiment 2 provides a lead-free piezoelectric thin film material, and the general chemical formula of the components of the lead-free piezoelectric thin film material is: (1-x)(Bi 0.5 Na 0.5 )TiO 3 -x%BaZrO 3 , where x=4.

[0063] The preparation method of the lead-free piezoelectric thin film material in the embodiment 2 specifically includes the following steps:

[0064] Step 1. Select the raw materials of bismuth acetate, sodium acetate, tetrabutyl titanate, barium acetate and tetrabutyl zirconate of analytical purity or above to prepare the BNT-4BZ precursor solution. The concentration of the precursor solution is 0.35mol / L. The volume of the solution is 35mL; since the alkali metal elements Bi and Na are easily volatilized during annealing, when weighing bismuth acetate and sodium acetate, bismuth acetate is provided in excess of 3%, and sodium acetate is provided in excess of 10%.

[0065] Preparation process:

[0066] First, measure 10 mL of ethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com