Van-type filter press for preventing mud cake from sticking to filter cloth and method for separating from mud cake

A box-type filter press and filter cloth technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as inability to fall completely, mud cake residue, mud cake is difficult to fall, etc., to increase efficiency, The effect of increasing the amplitude and reducing the manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

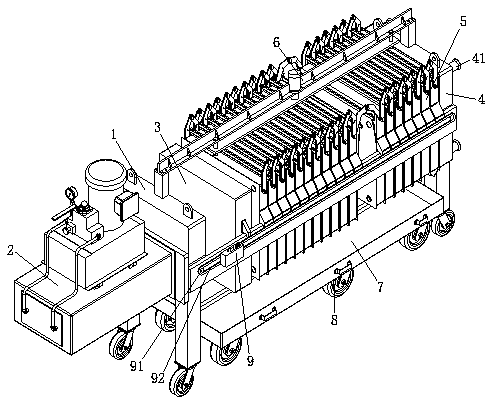

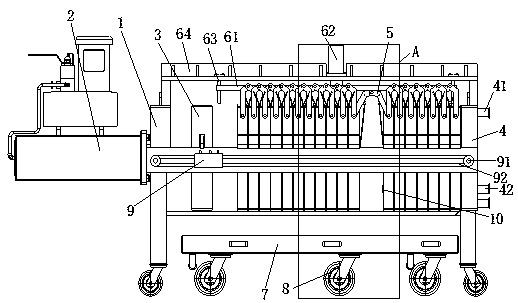

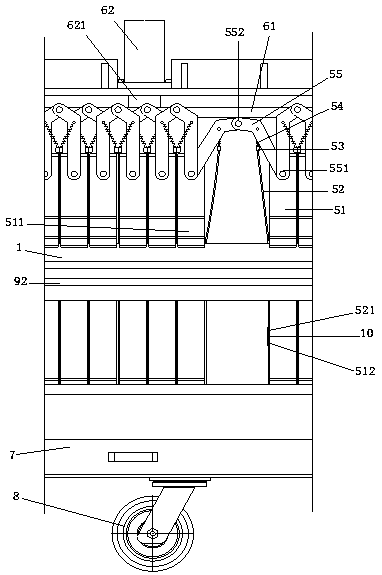

[0021] as attached Figures 1 to 2 As shown, a box-type filter press for preventing mud cake from sticking to the filter cloth includes a frame 1, and one end of the frame 1 is fixed with a pressure hydraulic cylinder 2 by bolts, and the frame 1 is provided with a pressure hydraulic cylinder 2. Tightening plate 3 and thrust plate 4, described pressing plate 3 is fixed on the piston rod of pressure hydraulic cylinder 2 by bolt, and described thrust plate 4 is fixed on the end of frame 1 away from pressure hydraulic cylinder 2 by bolt; The thrust plate 4 is provided with cleaning pipes 41 and feed pipes 42, wherein the cleaning pipes 41 are respectively arranged on the four corners of the thrust plate 4, and the feed pipe 42 is arranged at a position lower than the center of the thrust plate 4 , so that the lower end of the filter cloth 52 can be convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com