Agricultural ditch and ridge pesticide spraying and film laminating integrated device

A film device, furrow and ridge technology, which is applied in the field of agricultural furrow and ridge spraying and film-covering integrated device, can solve the problems of low planting efficiency, easy slipping, and heavy workload of farmers, so as to avoid manual film pressing and avoid The effect of strong wind blowing and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

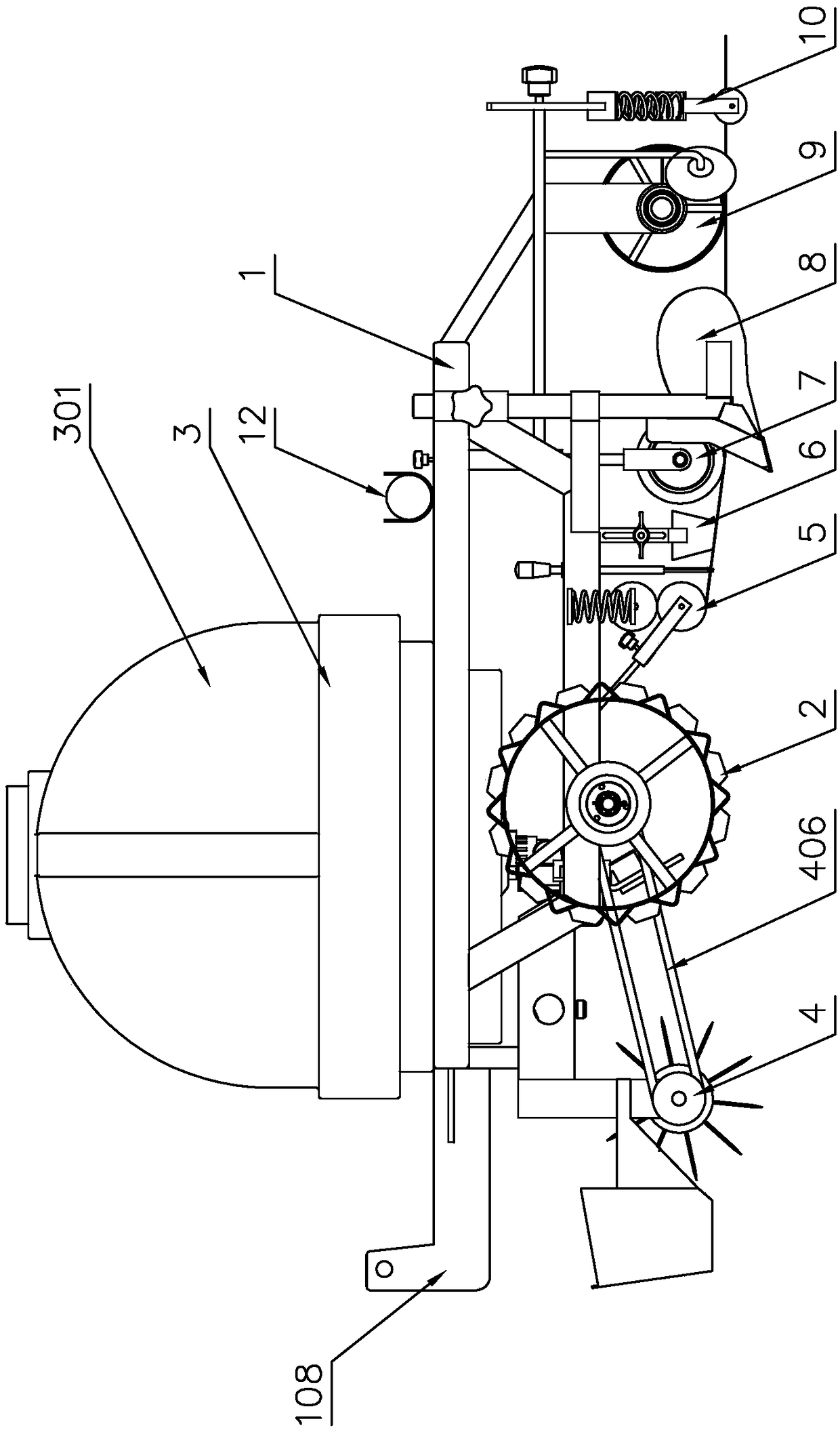

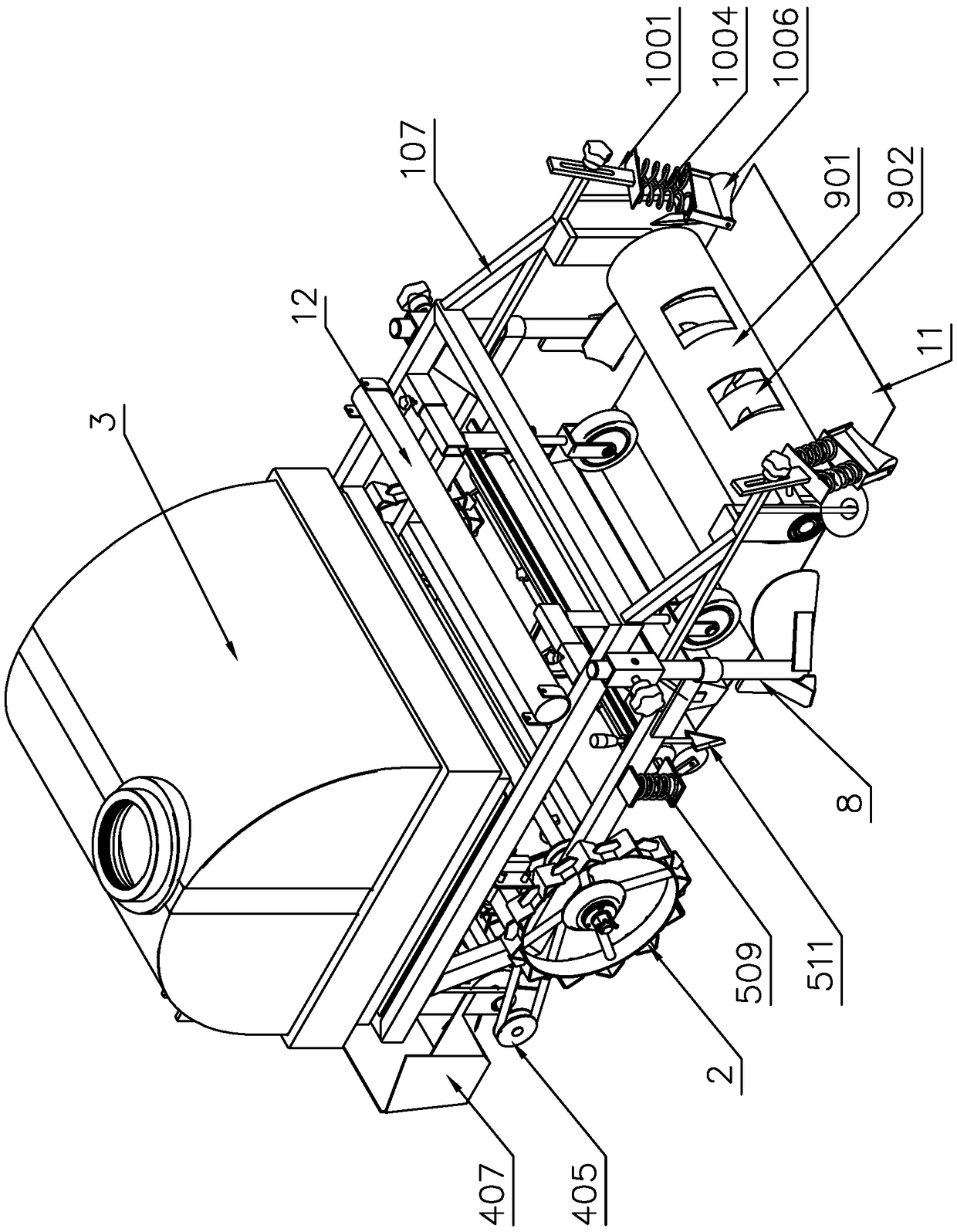

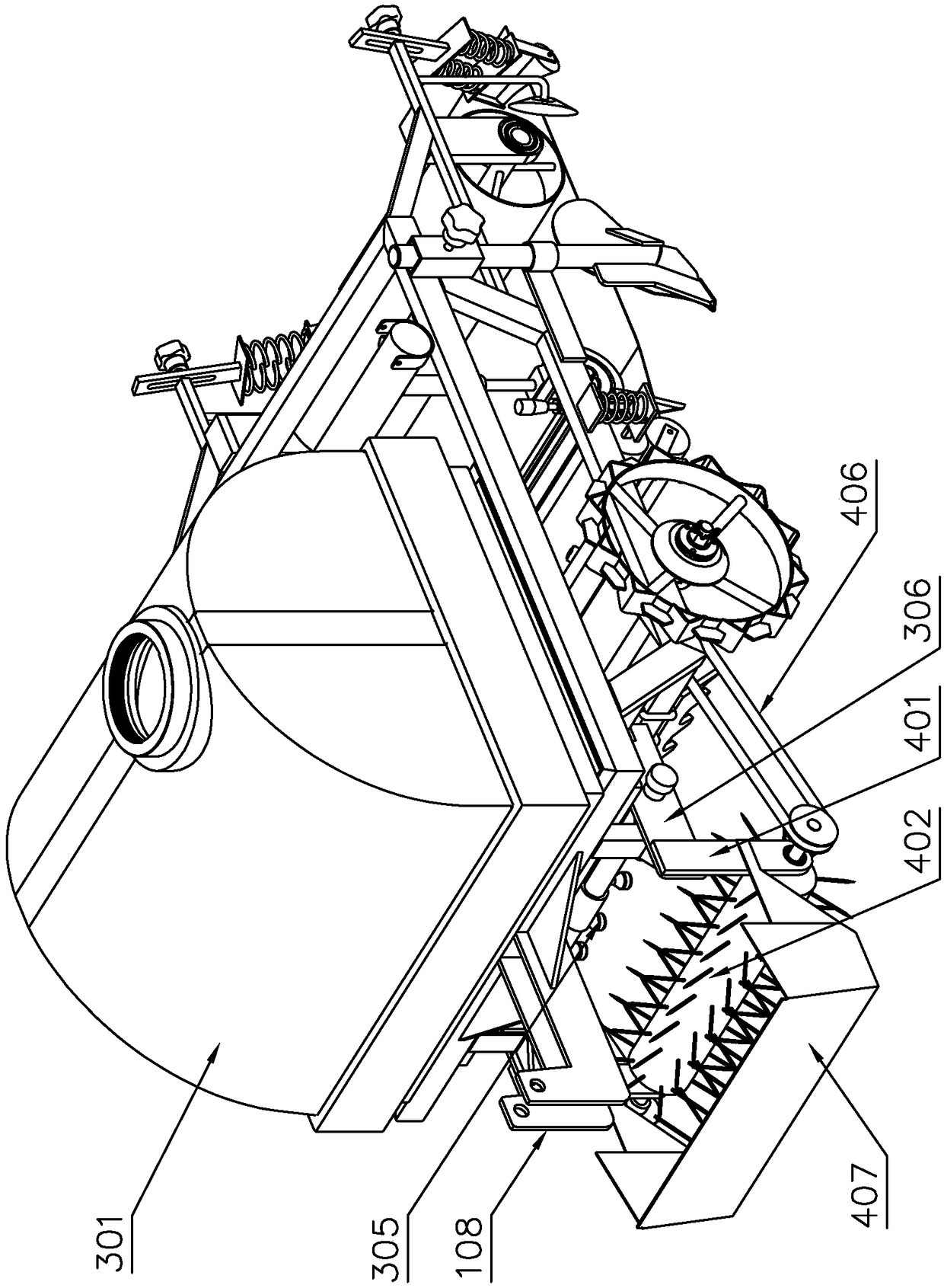

[0051] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-17 , to further specifically describe the technical solution of the present invention.

[0052] Such as Figure 1-4 Shown:

[0053] An integrated device for pesticide spraying and film coating in furrows and ridges for agriculture, comprising a frame 1, a roller 2, a pesticide spraying device 3, a film picking device 4, a film releasing mechanism 5, a film pressing mechanism 7, a soil covering mechanism 8, and a soil pressing mechanism 10. The frame 1 includes an upper frame 101, a lower frame 102, and a connecting rod I105. Both the upper frame 101 and the lower frame 102 are frame structures connected end to end by square tubes. The upper frame 101 and the lower frame 102 are connected through a The rod I 105 is fixedly connected; the upper frame 101 is provided with a beam I 103, and the lower frame 102 is provided with a beam II 104; one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com