Multifunctional composite movable gantry friction stir welding device

A friction stir welding and multifunctional technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of lack of workpiece leveling and tracking flash processing functions, difficult to guarantee weld quality, and low production efficiency. Achieve the effects of avoiding flash cleaning, improving welding quality, and improving workpiece quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

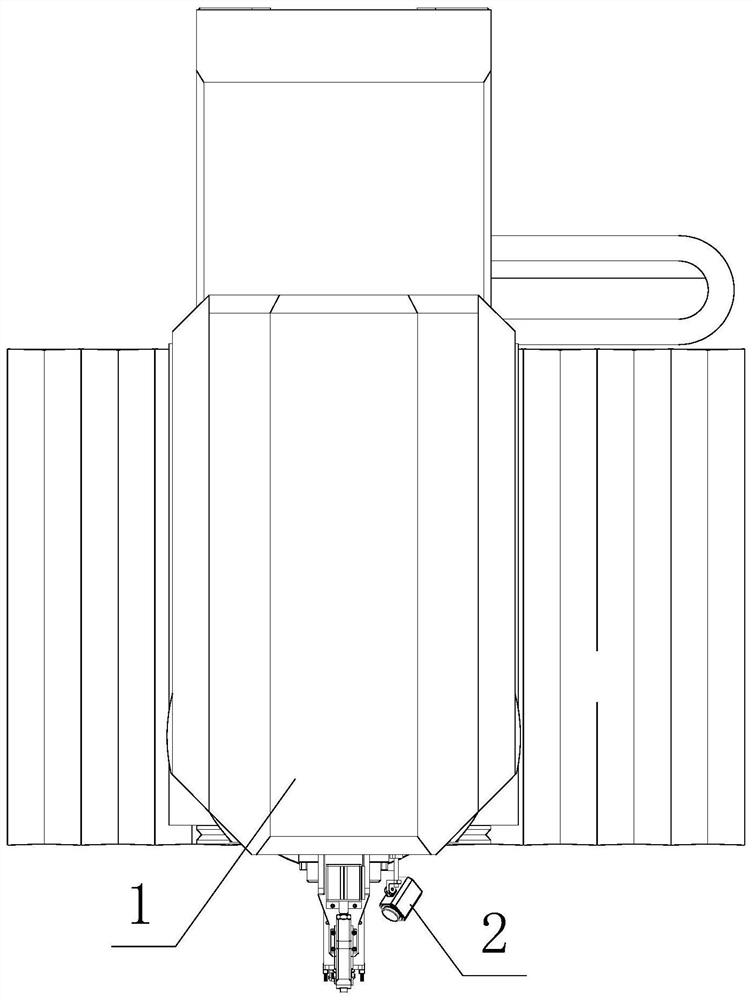

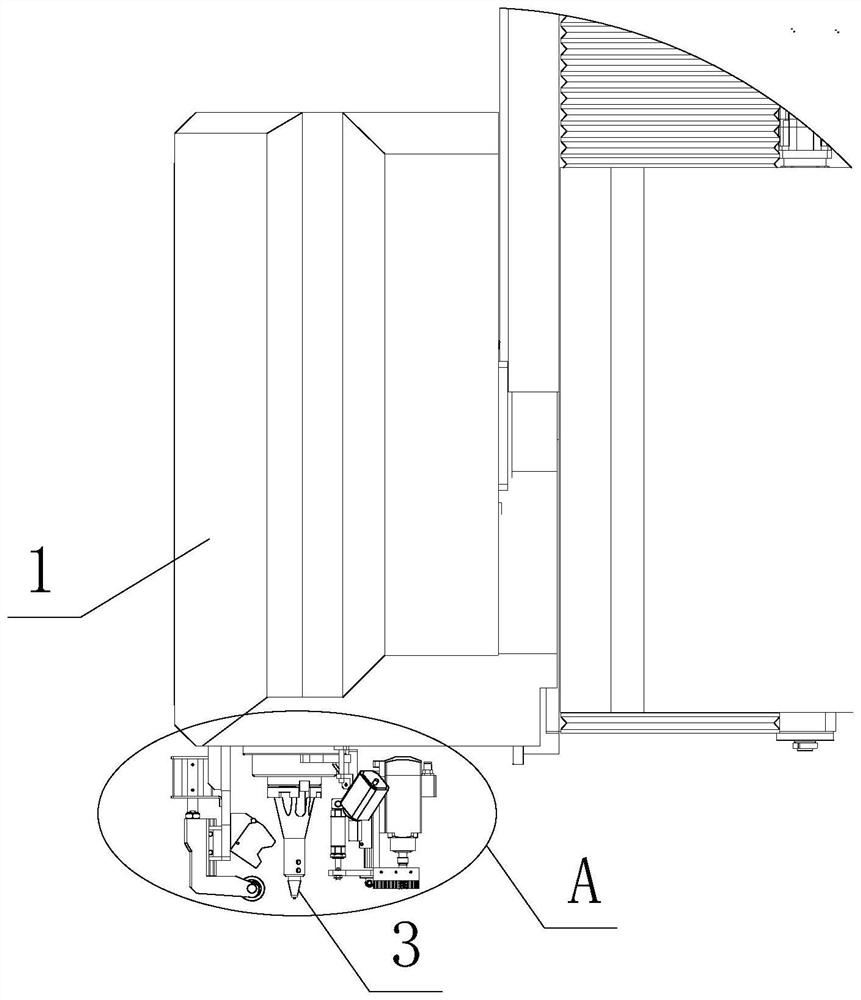

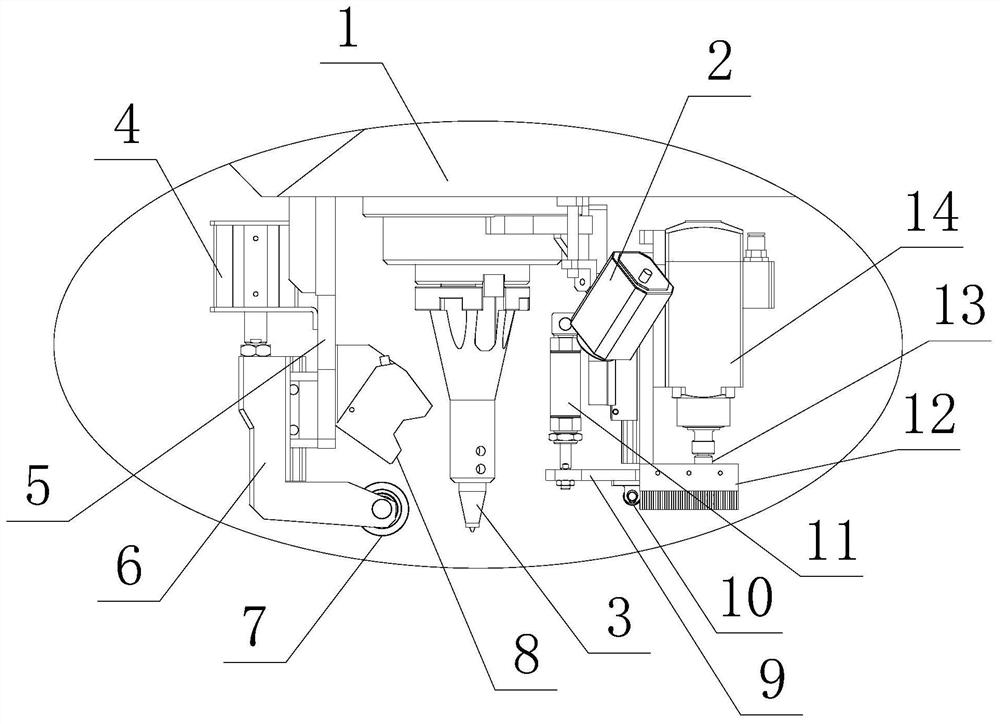

[0043] The multi-functional composite dynamic gantry friction stir welding equipment includes a head 1, the head 1 is provided with a main shaft along the vertical direction, the lower end of the main shaft is detachably connected with a friction stir welding tool 3, and the friction stir welding tool 3 is a stirring head; 1 is also equipped with welding pressing system, welding seam flash milling system, laser seam tracking system and video monitoring system.

[0044] specifically:

[0045] Welding and pressing system: including two sets of follower roller devices, one set of follower roller devices is located in front of the friction stir welding tool 3 and is mainly used for dynamic pressing and leveling of workpieces during welding, and the other set is The dynamic pressure roller is placed behind the friction stir welding tool 3, which can prevent warping and deformation of parts after welding and assist the welding seam flash milling system to grind the weld seam.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com