Rhizome crude medicine slicing device

A technology of slicing device and medicinal materials, applied in metal processing and other directions, can solve the problems of low tool safety and work efficiency, easy extrusion of the blade, side bending damage, stuck and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

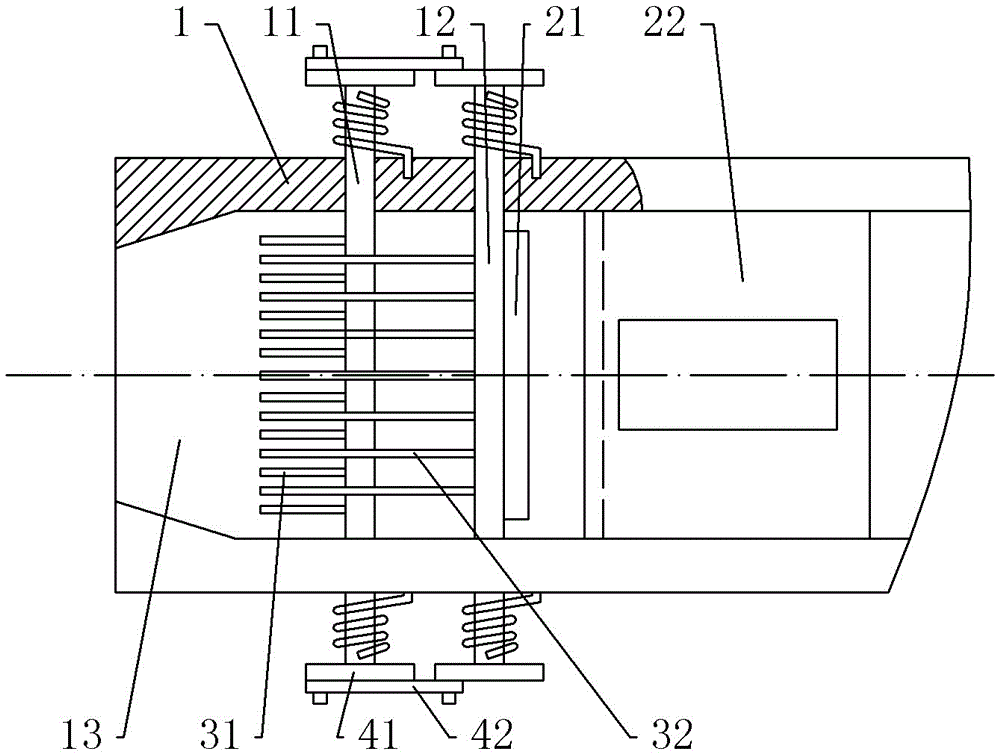

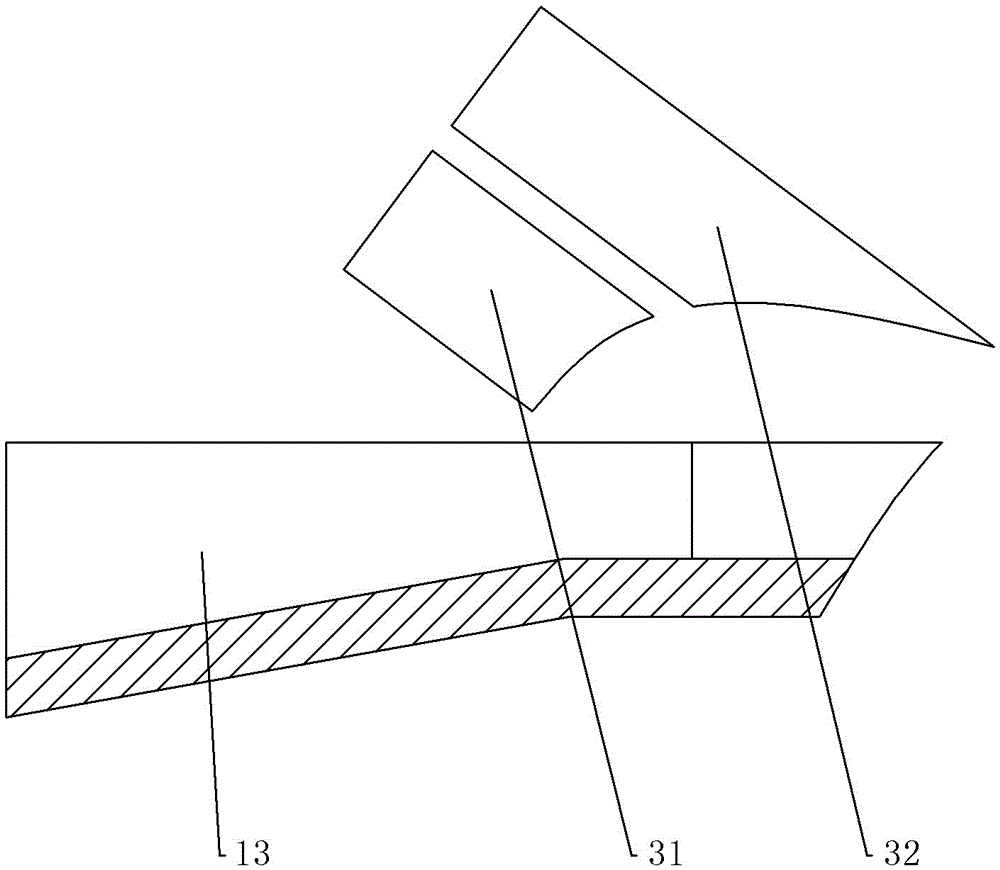

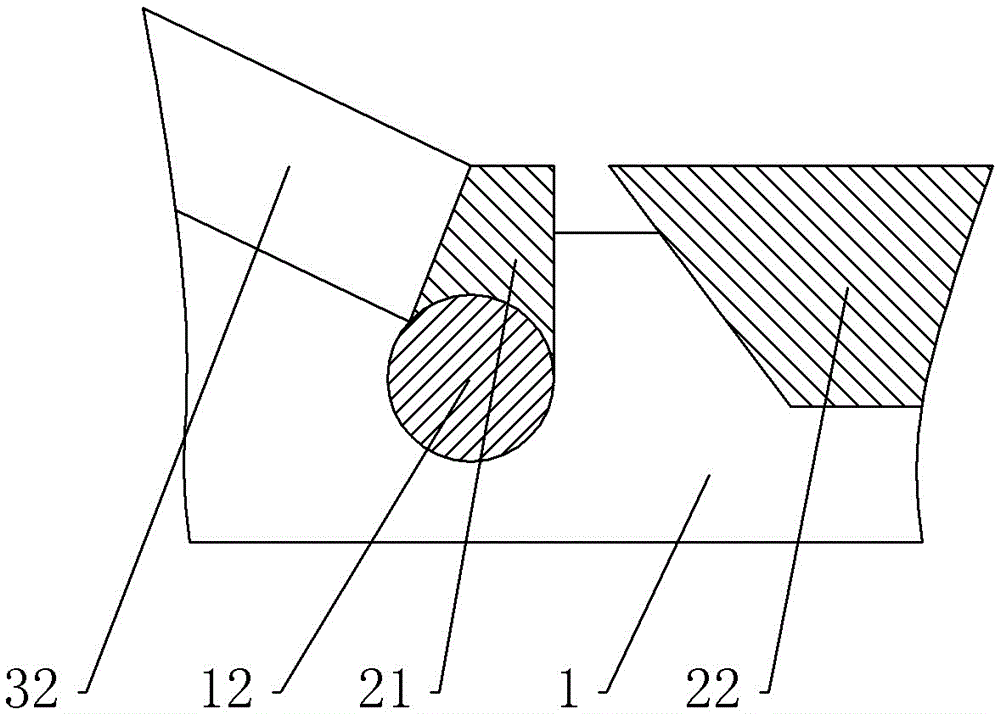

[0019] Basic as attached figure 1 , figure 2 , image 3 Shown: the rhizome medicinal material slicing device includes a frame 1, and the frame 1 is provided with a discharge chute 13, the discharge chute 13 is arranged on the front end of the frame 1, the bottom of the discharge chute 13 is inclined downward, and the discharge chute 13 The rear end to the front end gradually narrows; on the frame 1, a rotating shaft one 11 and a rotating shaft two 12 are also rotatably connected, wherein the rotating shaft one 11 and the rotating shaft two 12 are successively arranged behind the discharge trough 13, and the rotating shaft one 11 and the rotating shaft two The two ends of 12 are respectively provided with torsion springs, blade group 1 31 is fixed on rotating shaft 11, and blade group 2 32 is fixed on rotating shaft 2 12, blade group 1 31 and blade group 2 32 are all made up of ten blades The spacing between blade group one 31 and blade group two 32 blades is the same, and t...

Embodiment 2

[0023] The difference between the second embodiment and the first embodiment is that in the second embodiment, the bottom of the discharge chute and the blades of the blade set one and the blade set two are not inclined, but the bottom of the discharge chute is provided with several strips A discharge port is formed, and the discharge port corresponds to a gap between adjacent blades of the blade set, and the width of the discharge port is larger than the gap between adjacent blades. After the medicinal material is cut into slices, the medicinal material slices will fall down from the discharge port.

Embodiment 3

[0025] Such as Figure 4 As shown, the difference between the third embodiment and the first embodiment is that in the third embodiment, the drive slider 22 and the wedge 21 are not provided, but an arc-shaped gap is provided on the linkage wheel 41 of the second rotating shaft, and Cam 44 is arranged at the rear of rotating shaft 2, and cam 44 is connected with frame 1 in rotation, and cam 44 is provided with rotating handle, and cam 44 corresponds to the arc-shaped gap; when rotating rotating handle, cam 44 will rotate, and cam 44 rotates When the side of the arc-shaped gap will be squeezed, the rotating shaft 2 12 will be rotated. After the highest point of the cam 44 leaves the arc-shaped gap, the rotating shaft 2 12 will return.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com