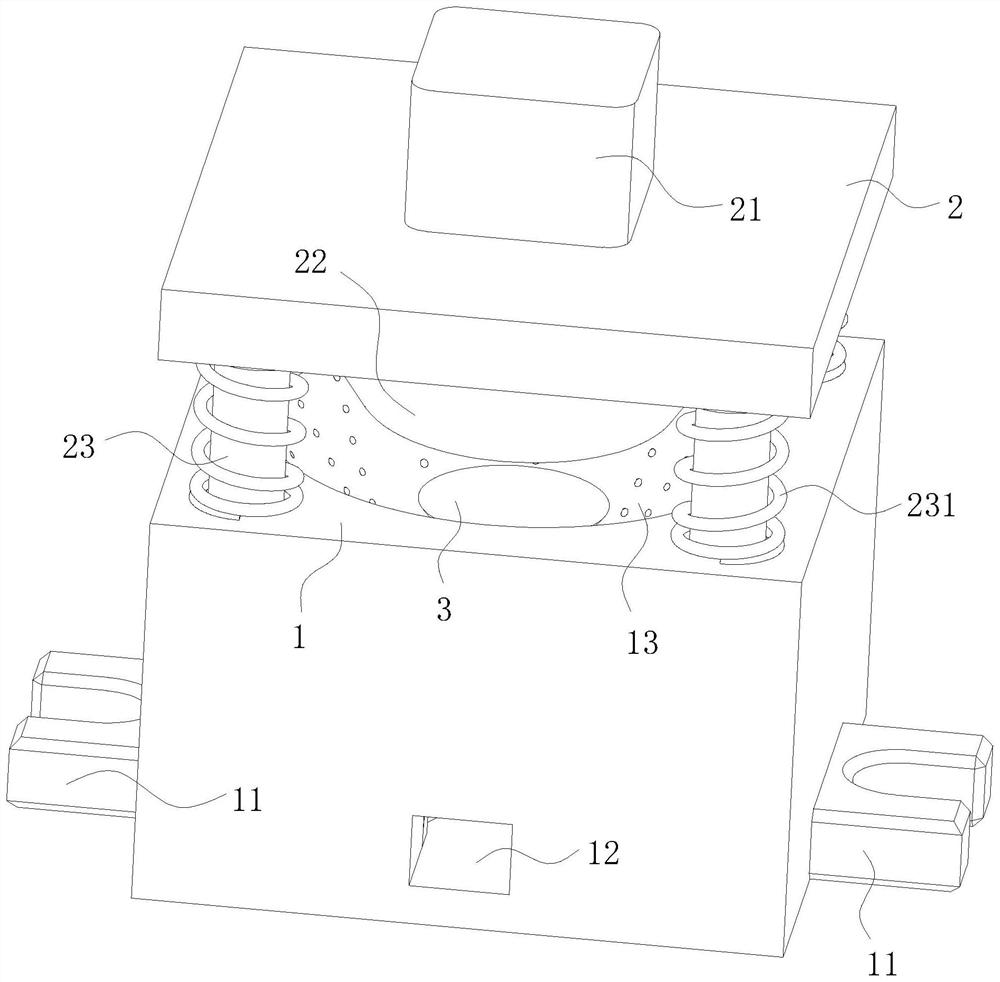

Stamping mold

A technology for stamping dies and mold bases, which is applied in the direction of forming tools, manufacturing tools, cleaning methods and appliances, etc. It can solve the problems of waste chips affecting the stamping process quality and processing efficiency, and manual cleaning of waste chips at regular intervals, so as to improve processing quality, The effect of speeding up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

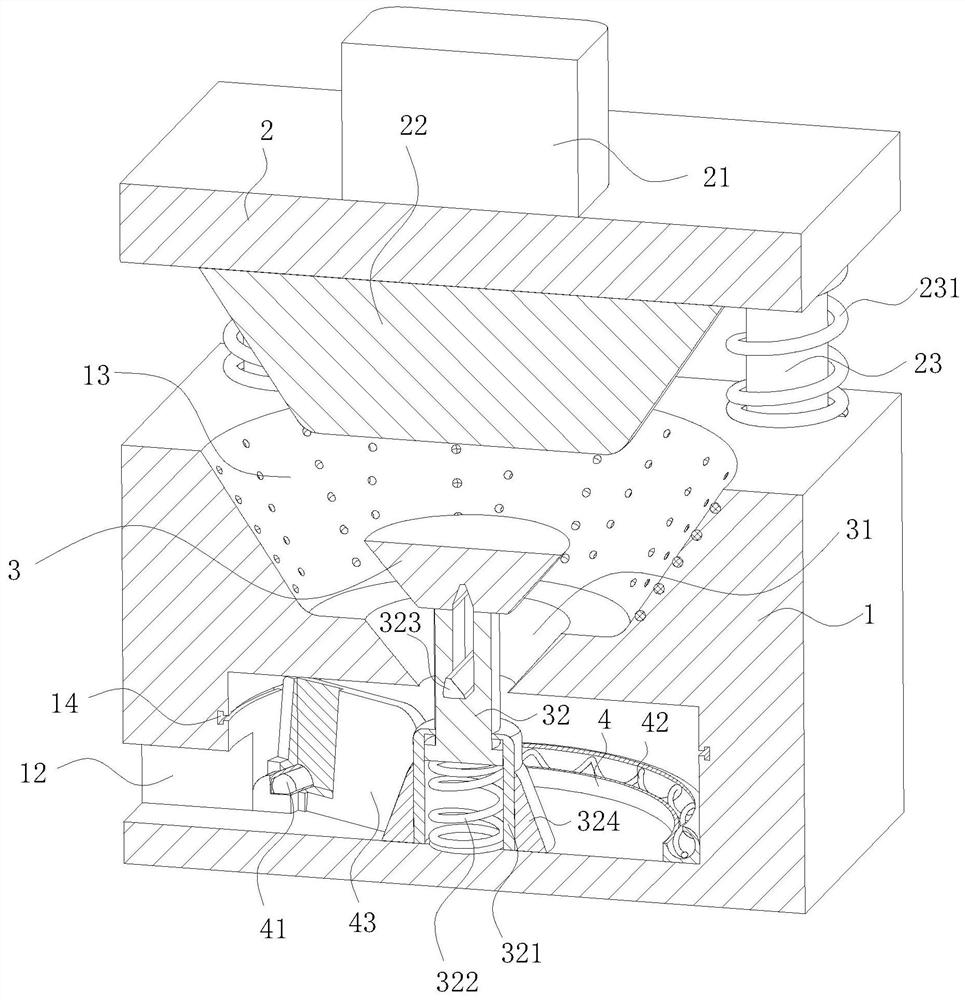

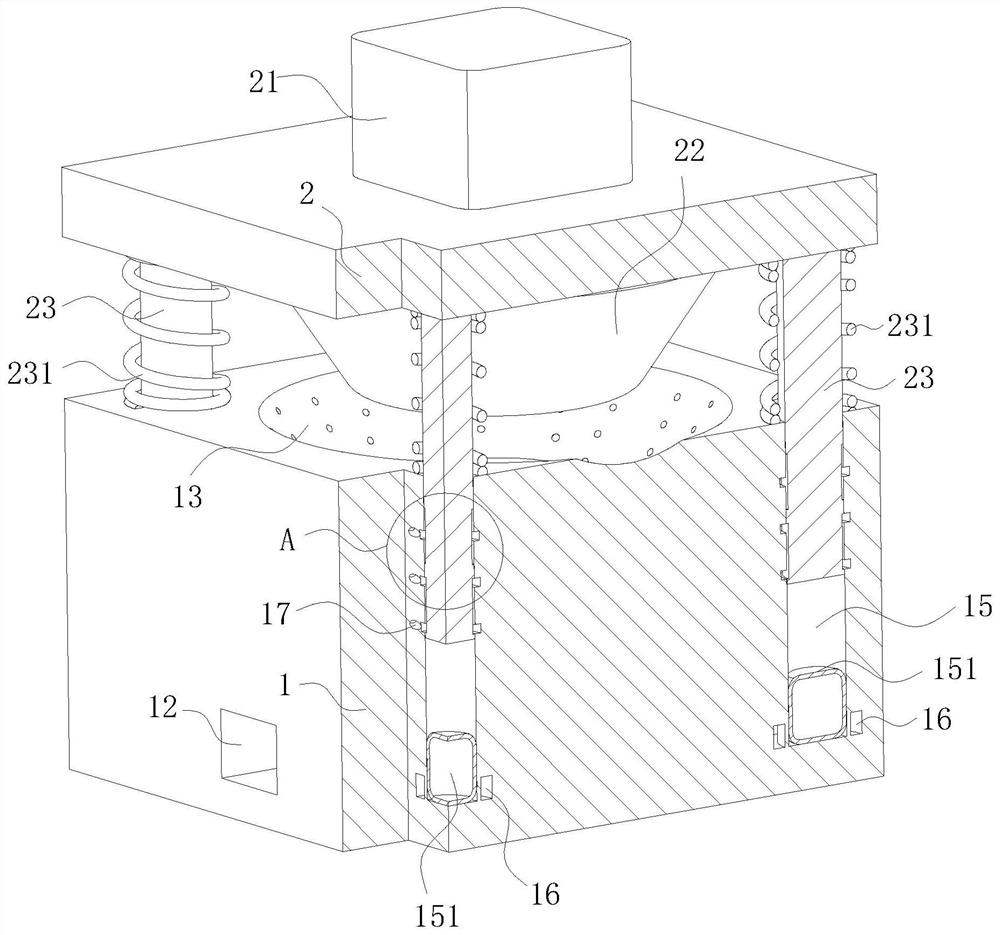

[0030] As an embodiment of the present invention, the cross-section of the fixed cross bar 323 is trapezoidal, and the length of the upper bottom of the trapezoid is less than the length of the lower bottom; micropores 2 are opened on the slopes on both sides of the fixed cross bar 323; The opening of the second microhole is facing the side wall of the blanking port; the second microhole is communicated with the first cavity through a pipeline;

[0031] During work, when the stamping is completed, when the extension post 32 rises under the action of the spring two 322, the space above the extension post 32 in the cavity one begins to shrink, the pressure increases, and the gas enters the micropore two through the pipeline and The gas ejected from the microhole 2 can blow the waste chips stuck at the falling hole 31 during the falling process, so that the waste chips can enter the collection chamber through the falling hole 31 and prevent the waste chips from falling during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com