Urban solid waste treatment device

A technology of municipal solid waste and treatment device, which is applied in the field of municipal solid waste treatment device, can solve the problems of low practicability, high energy consumption, and failure to consider the influence of filter nets, etc., so as to improve practicability, improve work efficiency, avoid stacking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

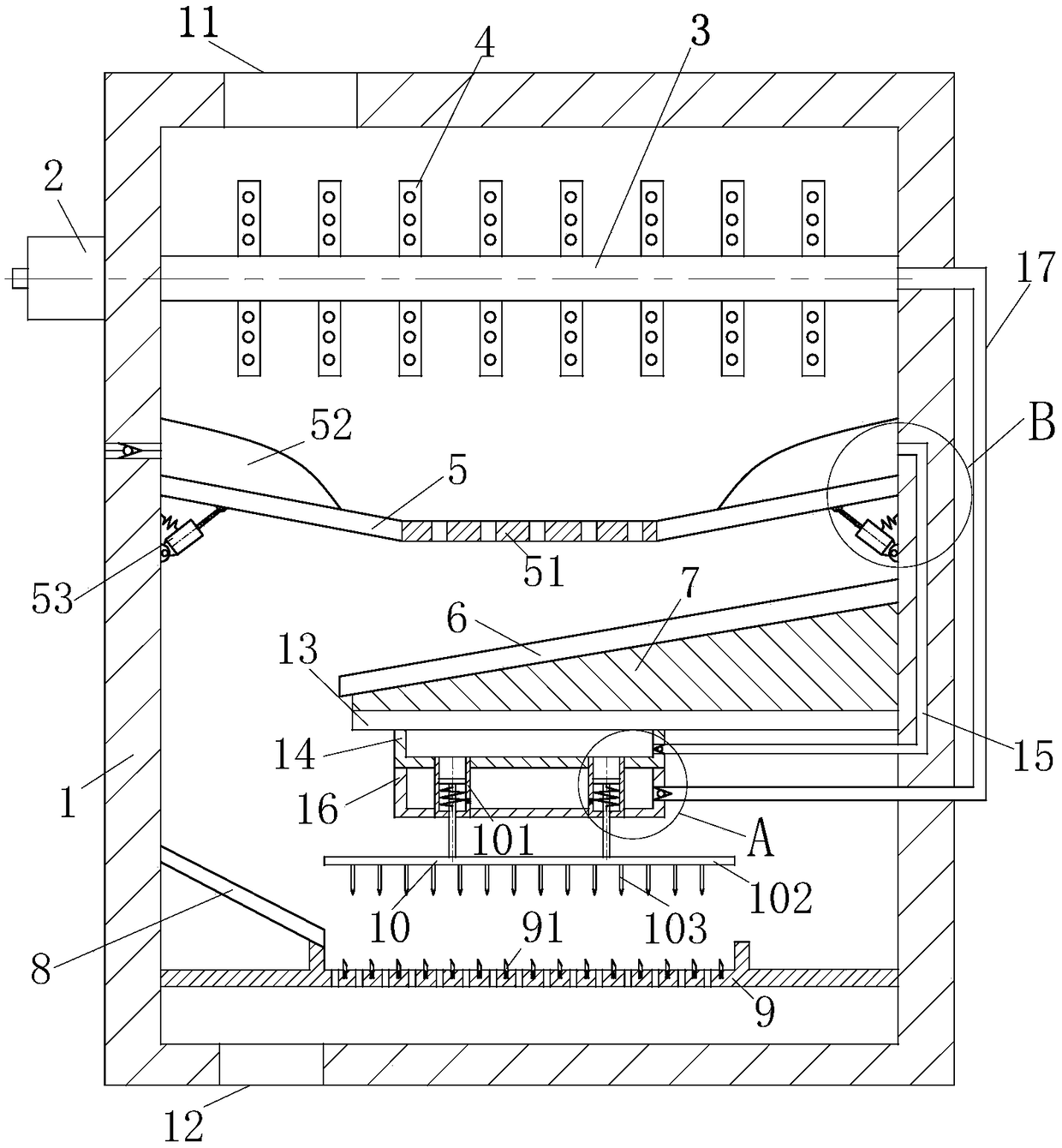

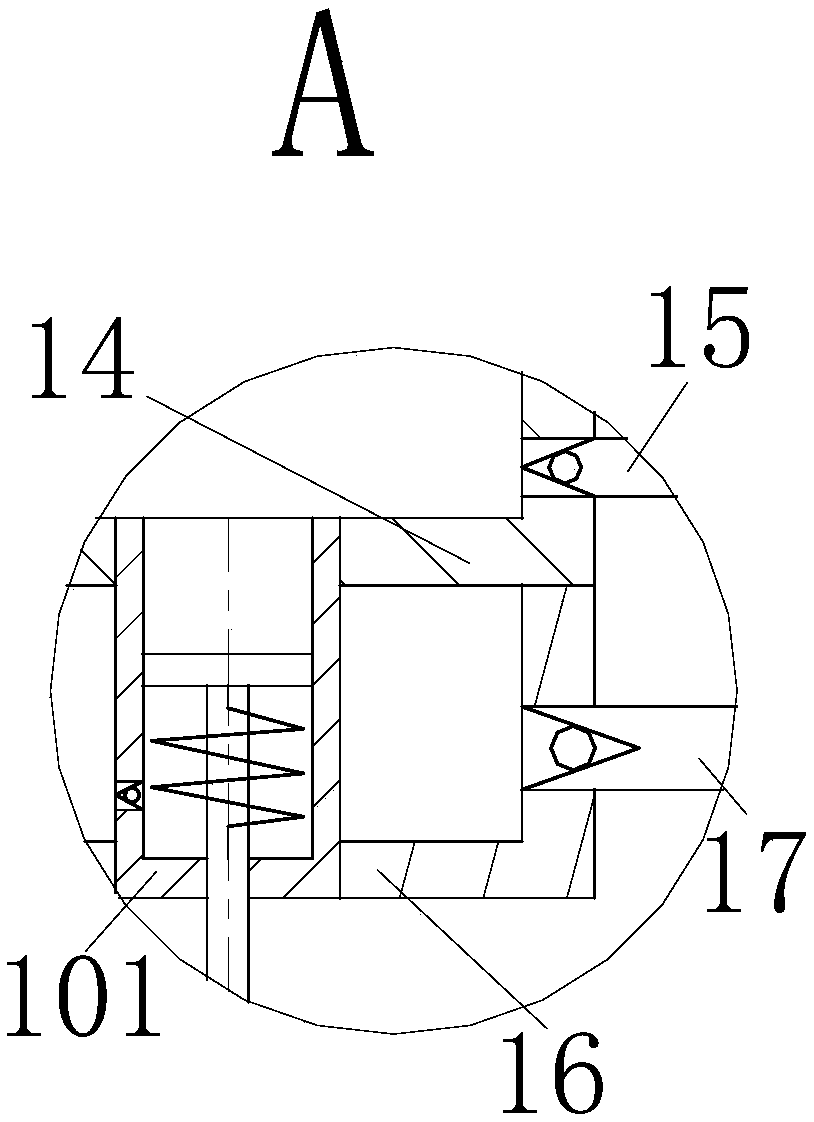

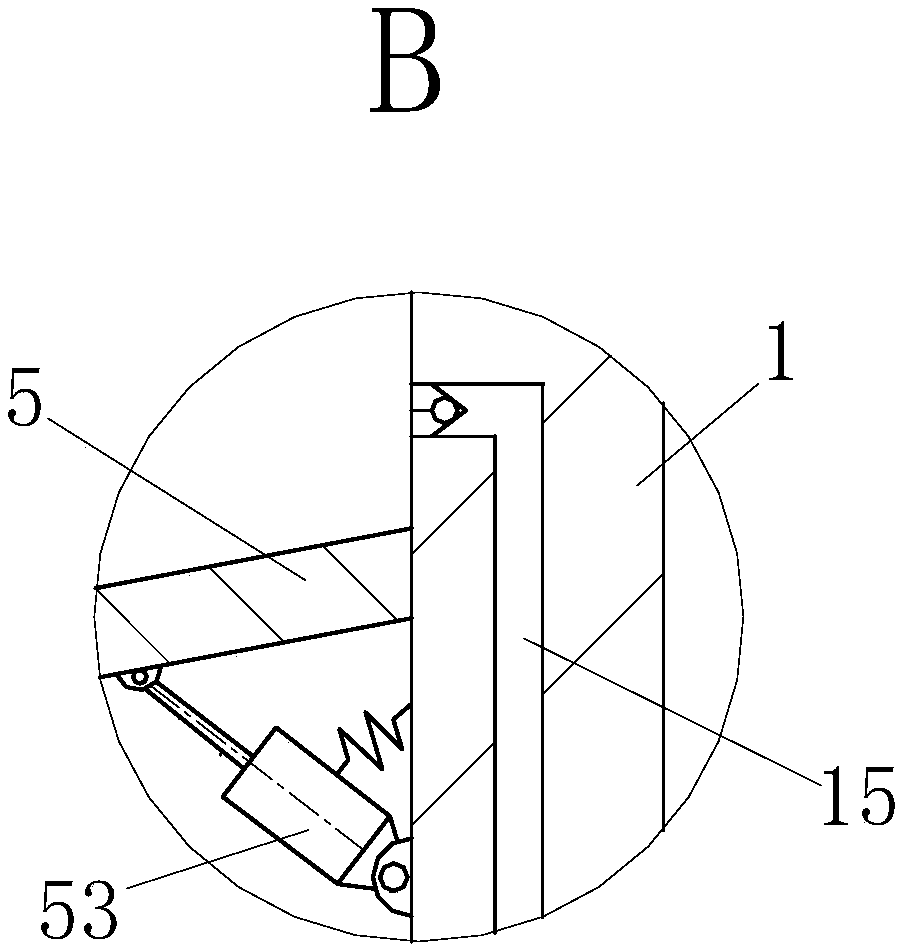

[0022] use Figure 1-Figure 3 The structure of the low-energy-consumption solid waste treatment device according to one embodiment of the present invention will be described as follows.

[0023] like figure 1 As shown, a kind of municipal solid waste treatment device according to the present invention includes a box body 1, a motor 2, a connecting shaft 3, a crushing rod 4, a partition 5, a No. 1 slideway 6, a high-temperature disinfection module 7, and a No. 2 slideway. Road 8, No. 1 filter screen 9 and extruding module 10; Described casing 1 is provided with feed inlet 11 and discharge outlet 12; Described feed inlet 11 is positioned at the top of casing 1, and feed inlet 11 is used for Input solid waste into the box 1; the discharge port 12 is located below the box 1, and the discharge port 12 is used to discharge the treated solid waste out of the box 1; the motor 2 is fixed on the upper left of the box 1 The connecting shaft 3 is located in the box body 1, and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com