Test piece mold release device for civil engineering tests

A technology for civil engineering and testing, applied in the field of civil engineering, can solve the problems of small single stroke of the jack and poor operation continuity, and achieve the effects of reducing friction, improving work efficiency and improving demolding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

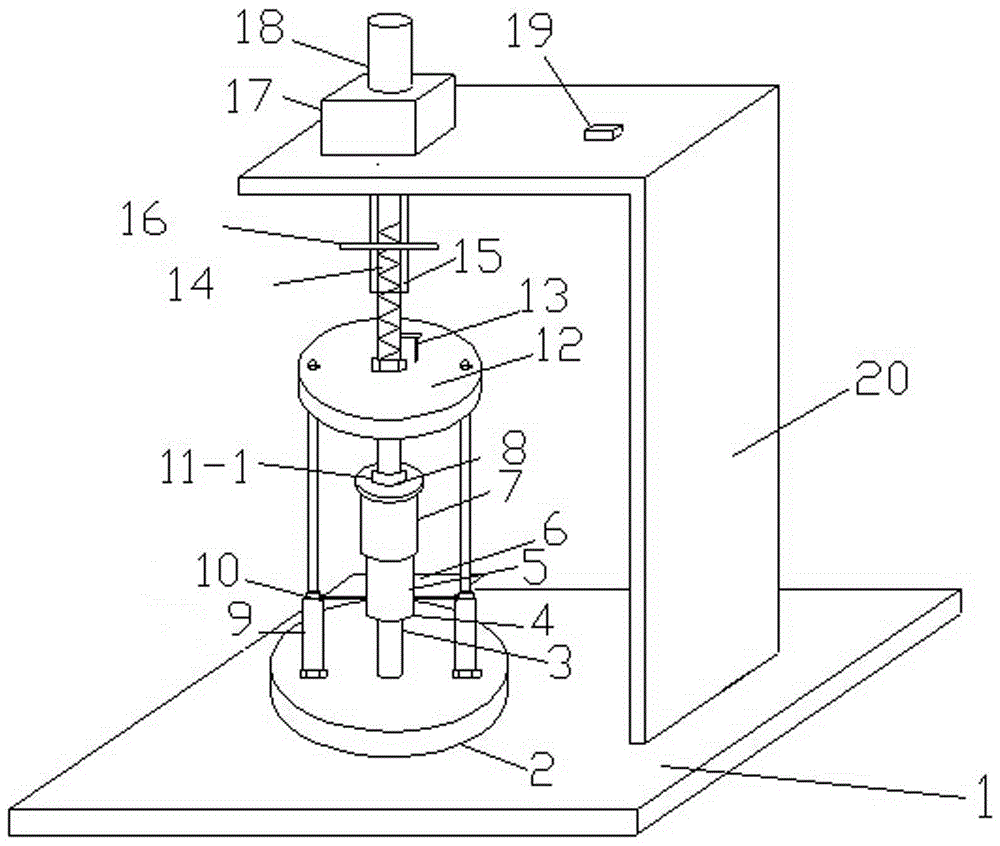

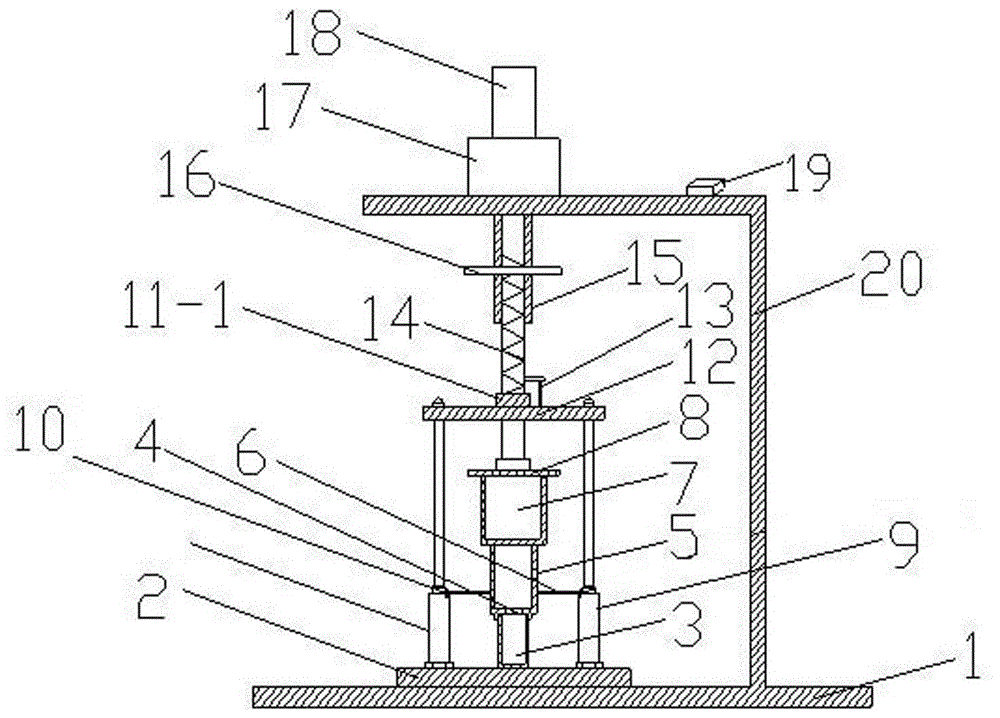

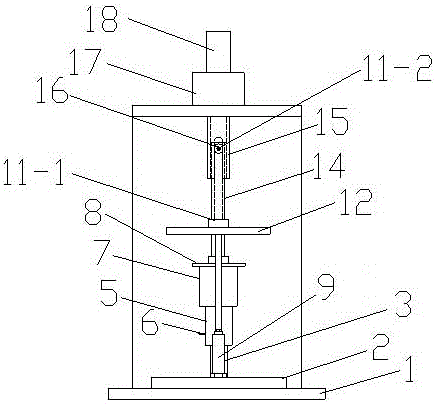

[0025] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

[0026] As shown in the figure, a sample demoulding device for civil engineering tests includes a base 1, a base plate 2 and a bracket 20, the bracket 20 is a crank arm structure, the base plate 2 is arranged on the base 1, and between the base plate 2 and the bracket 20 A demoulding device is installed in the space between, and the demoulding device includes a test piece cylinder positioning mechanism and a screw propulsion mechanism, and the test piece cylinder 5 to be demoulded is installed and positioned through the test piece cylinder positioning mechanism to prevent the test piece cylinder 5 from being demoulded. Offset occurs during the molding process to ensure the integrity of the test piece after demolding, and the loading screw 14 is rotated to push the test piece in the test piece cylinder 5 out of the test piece cylinder 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com