Sleeper embedded bushing positioning device, and positioning and demouding method

A technology of positioning device and sleeve, applied in the field of sleeper manufacturing, can solve the problems of easy damage of rubber bolts, unsatisfactory application effect, difficulty in demoulding, etc., and achieve the effects of reducing damage, improving demoulding work efficiency, and being easy to operate and master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

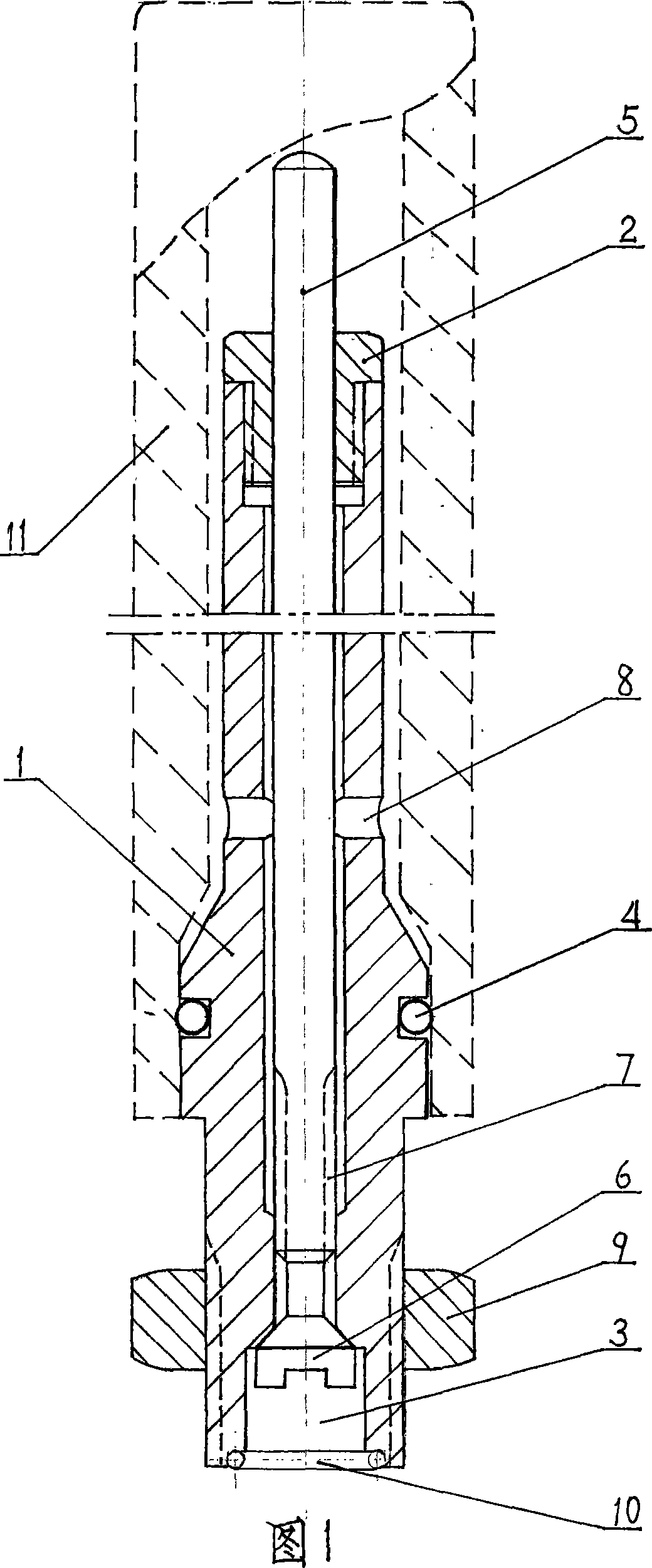

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] As shown in Figure 1, the sleeper pre-embedded casing positioning device of the present invention includes a tube body 1 with a lumen in the center, a center nut 2 is installed on one end of the lumen, and the other end is connected to an interface 3; There is a spool 5, one end of the spool 5 passes through the middle of the fixed core nut 2, and the other end is connected to a valve body 6 with a tapered surface, and the valve body 6 is arranged at the connection between the lumen and the interface 3; The valve core 5 is provided with a guide groove 7 along its length; the tube body 1 is provided with a hole 8 communicating with the outside of the lumen; the outer wall of the tube body 1 is provided with a sealing ring 4 and a fixing nut 9 .

[0022] In order to prevent impurities from entering the pipe body 1 during water injection, a filter 10 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com