Light insulation wallboard production line

一种保温墙板、生产线的技术,应用在陶瓷成型车间、辅助成型设备、卸料装置等方向,能够解决投资企业小经济负担、人工工作强度大、磕碰破损等问题,达到提升生产效率和产品质量、减少人工的投入、提高成型速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below in conjunction with the drawings and examples, so as to fully understand the present invention.

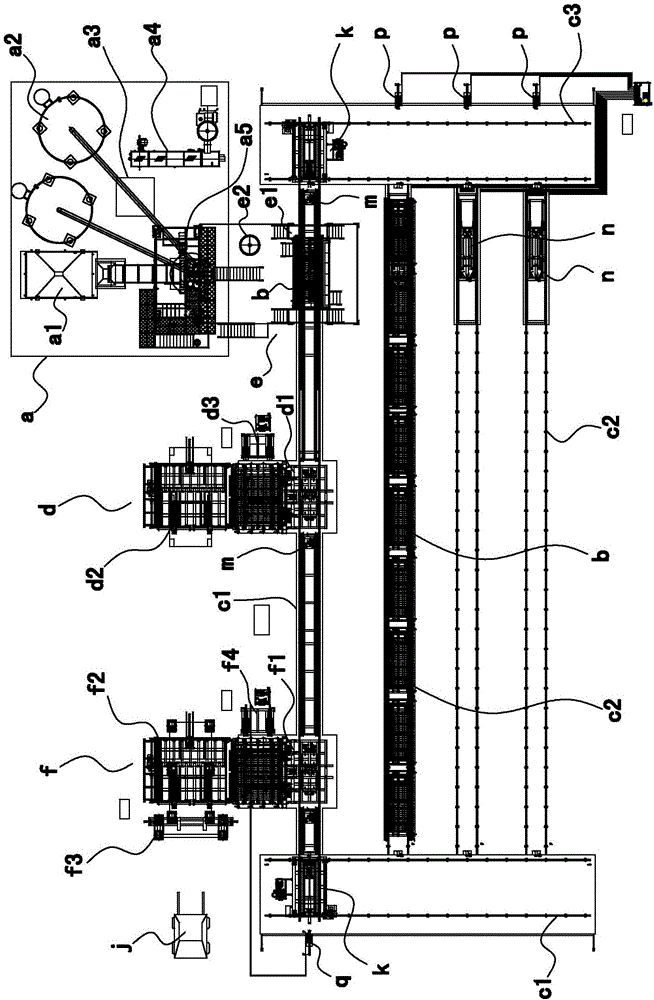

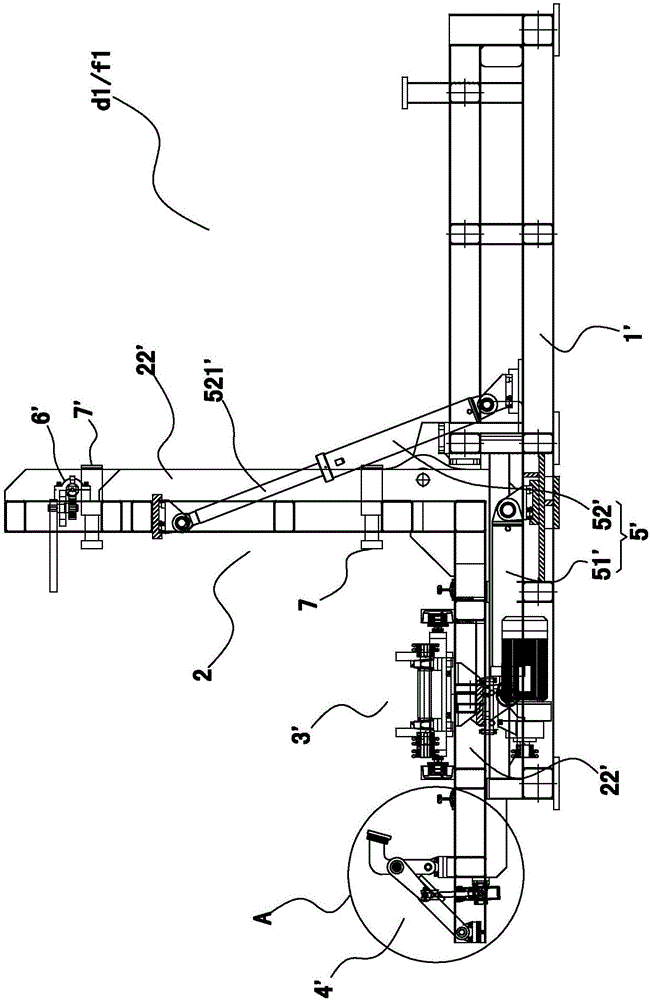

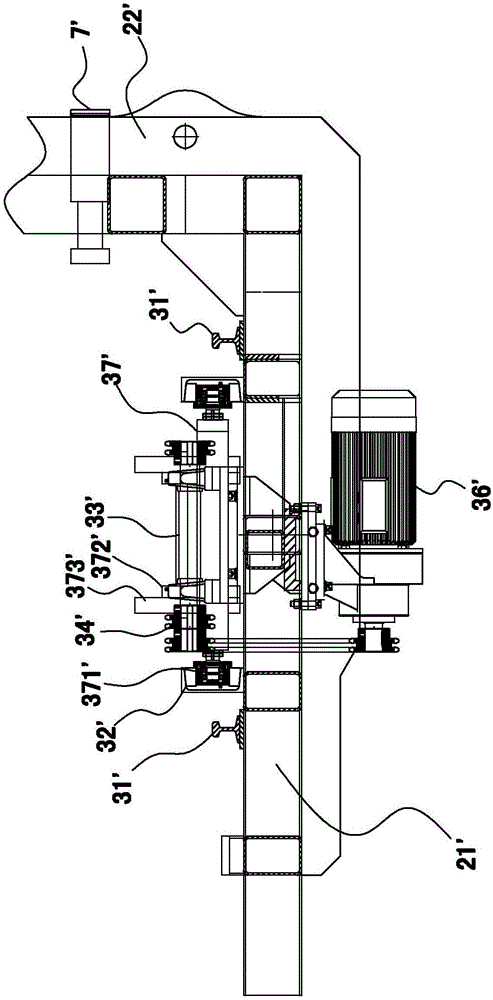

[0035] Such as figure 1 As shown, the light-weight thermal insulation wallboard production line of the present invention includes a control system for controlling mechanical automation in each part of the production line (not shown in the figure), a material preparation system a for wallboard forming materials, a wallboard forming machine b, and a wallboard forming machine for forming available walls. Panel forming machine b, track line network for continuous cycle production operation c, mold loading equipment for installing formwork and frame on wall panel forming machine b, grouting platform e for grouting wall panel forming machine b and after wall panel forming The demoulding equipment f.

[0036] The material preparation system a is the same as the material preparation system in the prior art,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com