Concrete briquette automatic demoulding device and demoulding method

A concrete test block and automatic demoulding technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve problems such as easy scratches, easy bump deformation, small holes easy to leak grout, etc., to achieve convenience and automation, guarantee Molding size, to ensure the effect of fastening connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

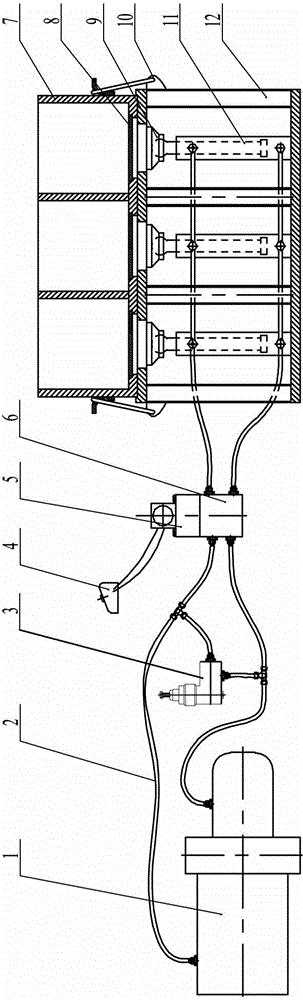

[0016] Such as figure 1 with figure 2 Shown: The embodiment of the present invention provides an automatically controlled concrete test block demoulding device and demoulding method, including a metal triple mold 7 provided with lugs, a demolding support 12 for a vertically fixed triple mold 7, and a jacking The three hydraulic cylinders 11 of the triple mold 7 and the hydraulic power unit 1. Each center of the bottom plate of the triple mold 7 is provided with a test mold pallet 8, and the upper end of the hydraulic cylinder 11 is hinged with a top on the center of the lower surface of the test mold pallet 8. Block 9, the bottom of the hydraulic cylinder 11 is welded and fixed with the demolding bracket 12, the hydraulic power 1 unit inlet and outlet are respectively connected with the electromagnetic reversing valve plate 6 and the direct-acting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com