Rotational molding mould and processing technology thereof

A rotational molding and processing technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of slow internal air flow, restrict the quality and development of all-plastic body molding, and have many surface bumps and features, and achieve improvement. The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

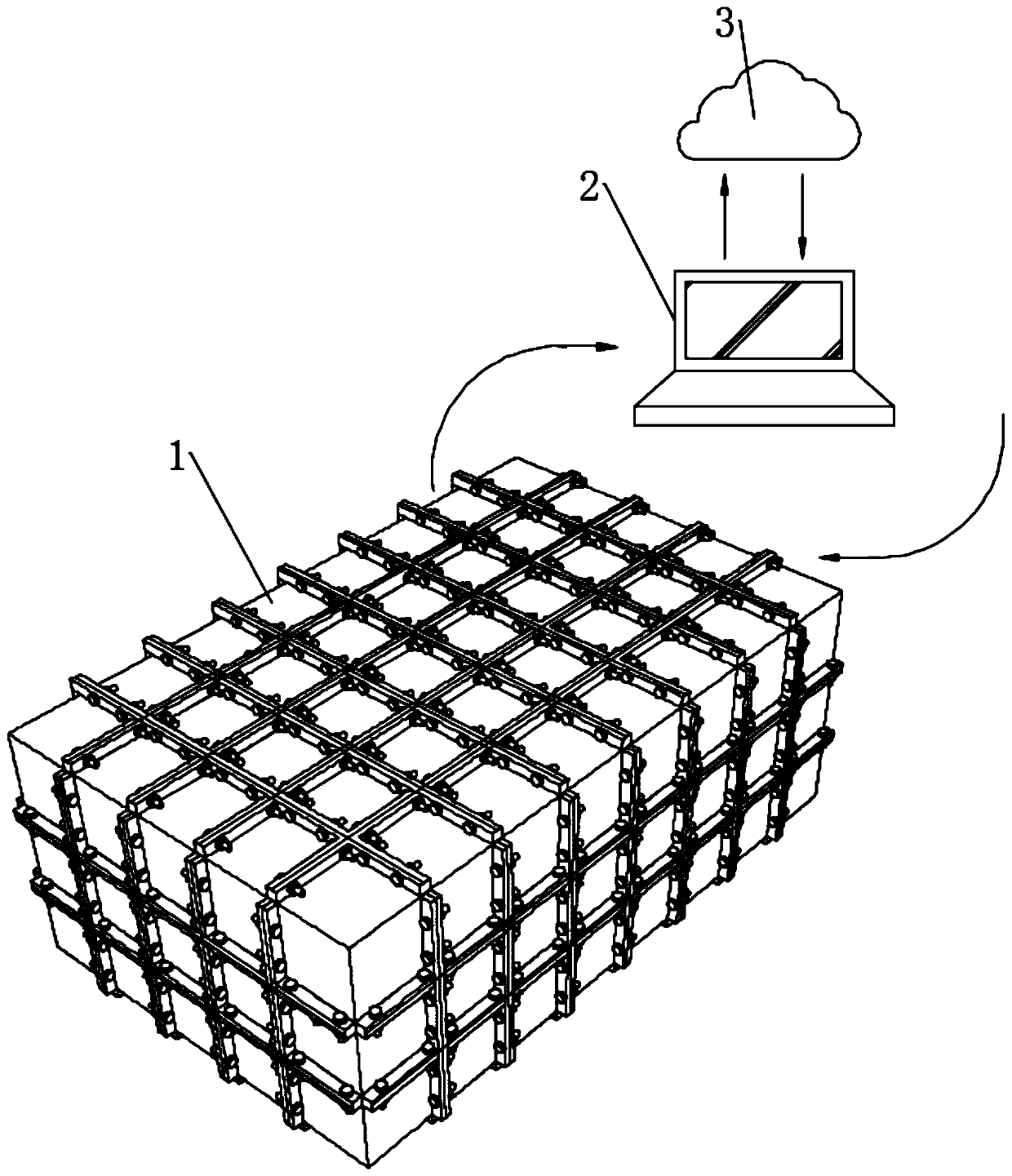

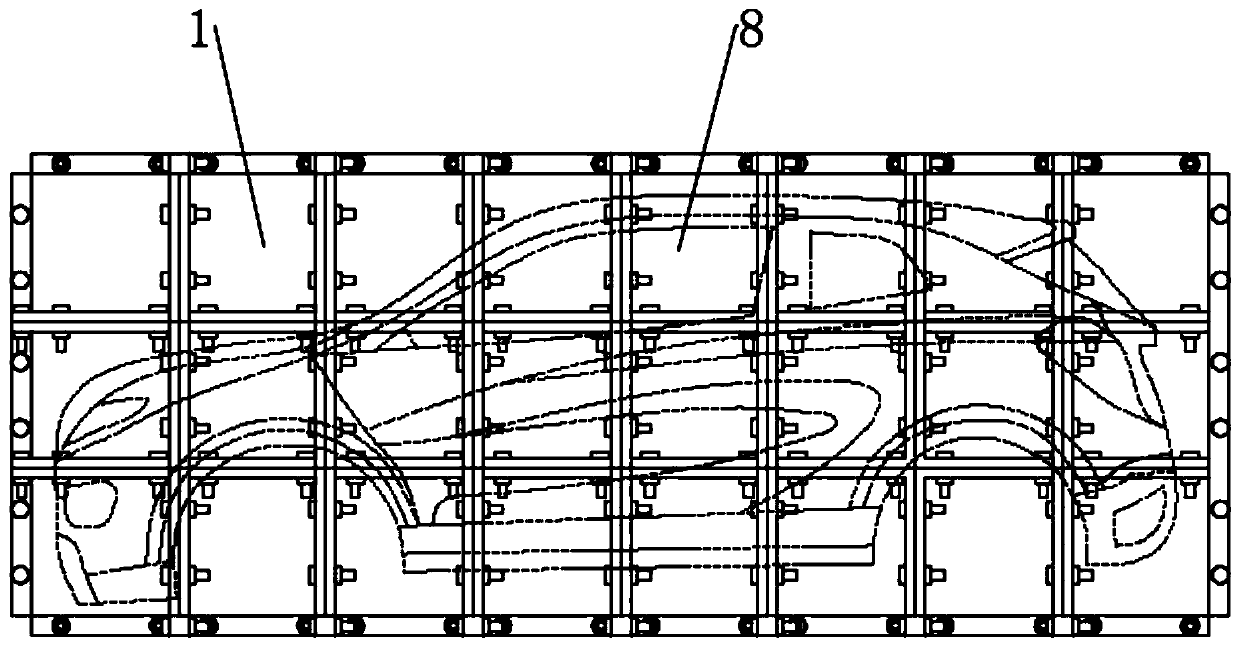

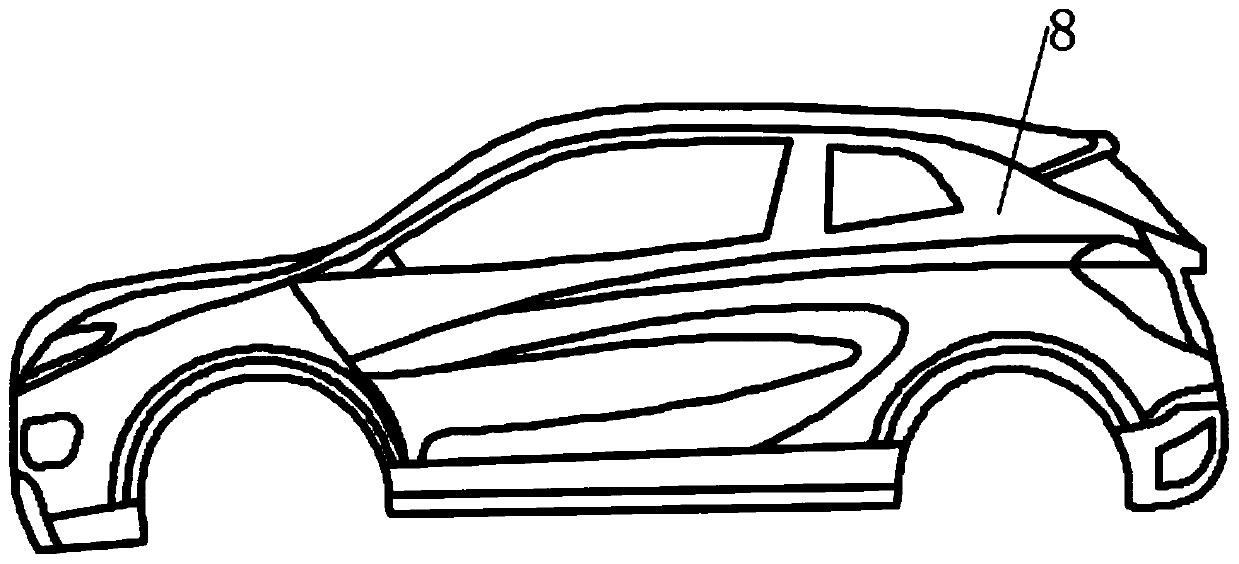

[0050] see Figure 1-2 , a rotational molding mold, including a mold body, the inner end of the mold body is dug with an all-plastic vehicle body cavity, and the mold body includes several mold subunits 1, for processing products with complex shapes such as all-plastic vehicle bodies, the mold volume and quality Large, complex surface structure, if the block method of irregular multi-directional mold is adopted, it is necessary to turn over and adjust the angle of the mold when installing and dismantling the mold, which makes opening and closing the mold difficult and inefficient When using a block mold, it is easy to reduce the assembly accuracy, and the installation and coordination between the block molds are misplaced. The method of dividing and combining large-scale and complex aluminum alloy mold units is used to divide the three-dimensional unit of the all-plastic body mold. The mold block method Mainly aiming at the shape of the mold cavity, directly divide the mold of...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that when the thickness of the all-plastic body is relatively thick, the "solid + foam + solid" sandwich reinforced all-plastic body structure only relies on the bonding force between surfaces, and the strength is difficult to meet the design requirements , so technicians can selectively install an electromagnet on the temperature control node 6, and the electromagnet is also electrically connected to the auxiliary control module 5, that is, the temperature control node 6 can realize dual control of temperature and magnetic field at the same time. The auxiliary material package and the glass fiber reinforced polyethylene resin are mixed with an appropriate amount of magnetic particles during the preparation process. The magnetic particles can be micro-nano-level Fe203, Fe304 or Ni particles, etc., and the first layer of glass fiber reinforced polyethylene resin is melted to cover the mold After the inner wall is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com