Automatic demolding device for prefabricated part

A technology for prefabricated components and automatic demoulding, which is applied in the direction of unloading devices, manufacturing tools, ceramic molding machines, etc., and can solve the problems of labor-intensive, inability to detect the surface molding of concrete prefabricated components, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

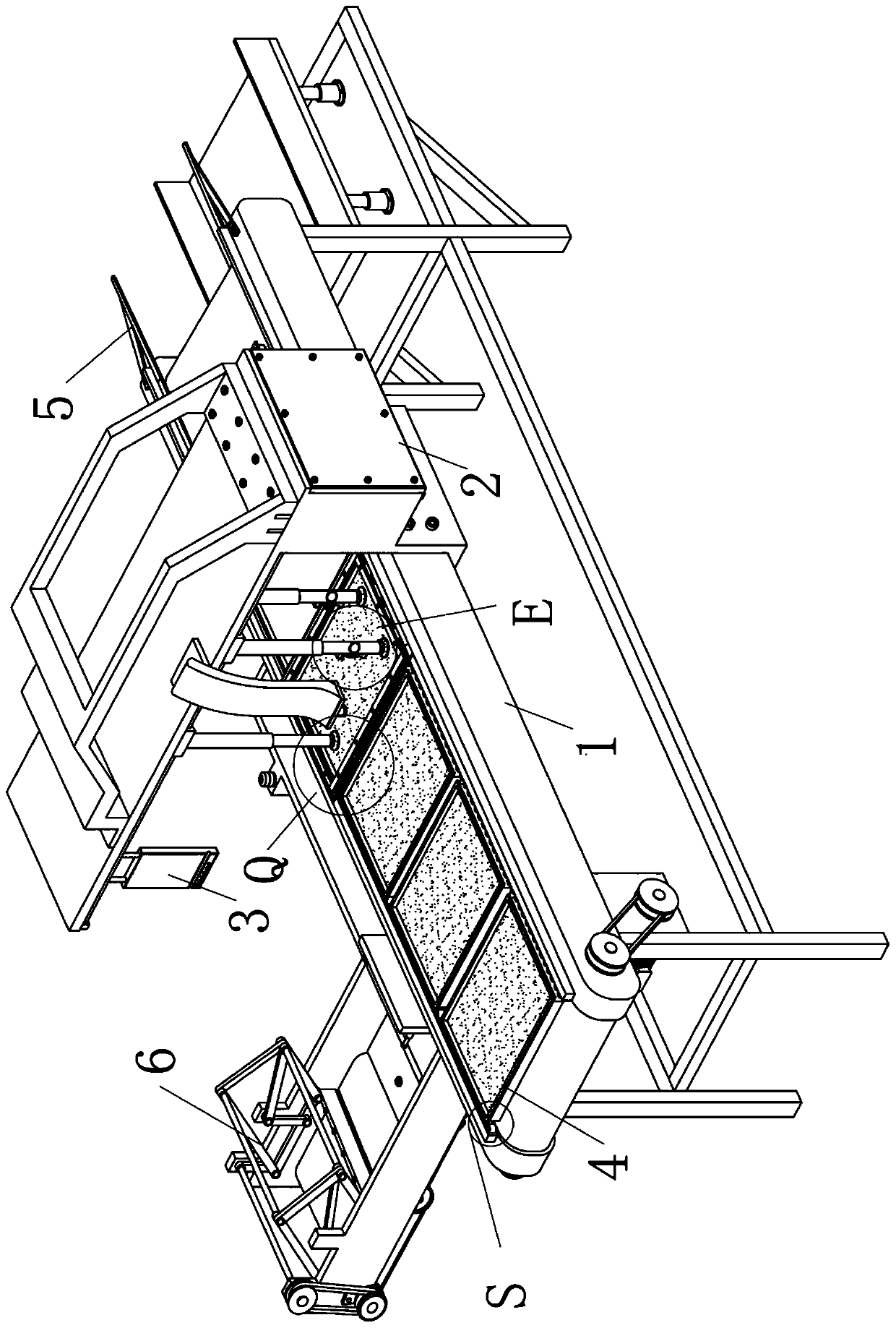

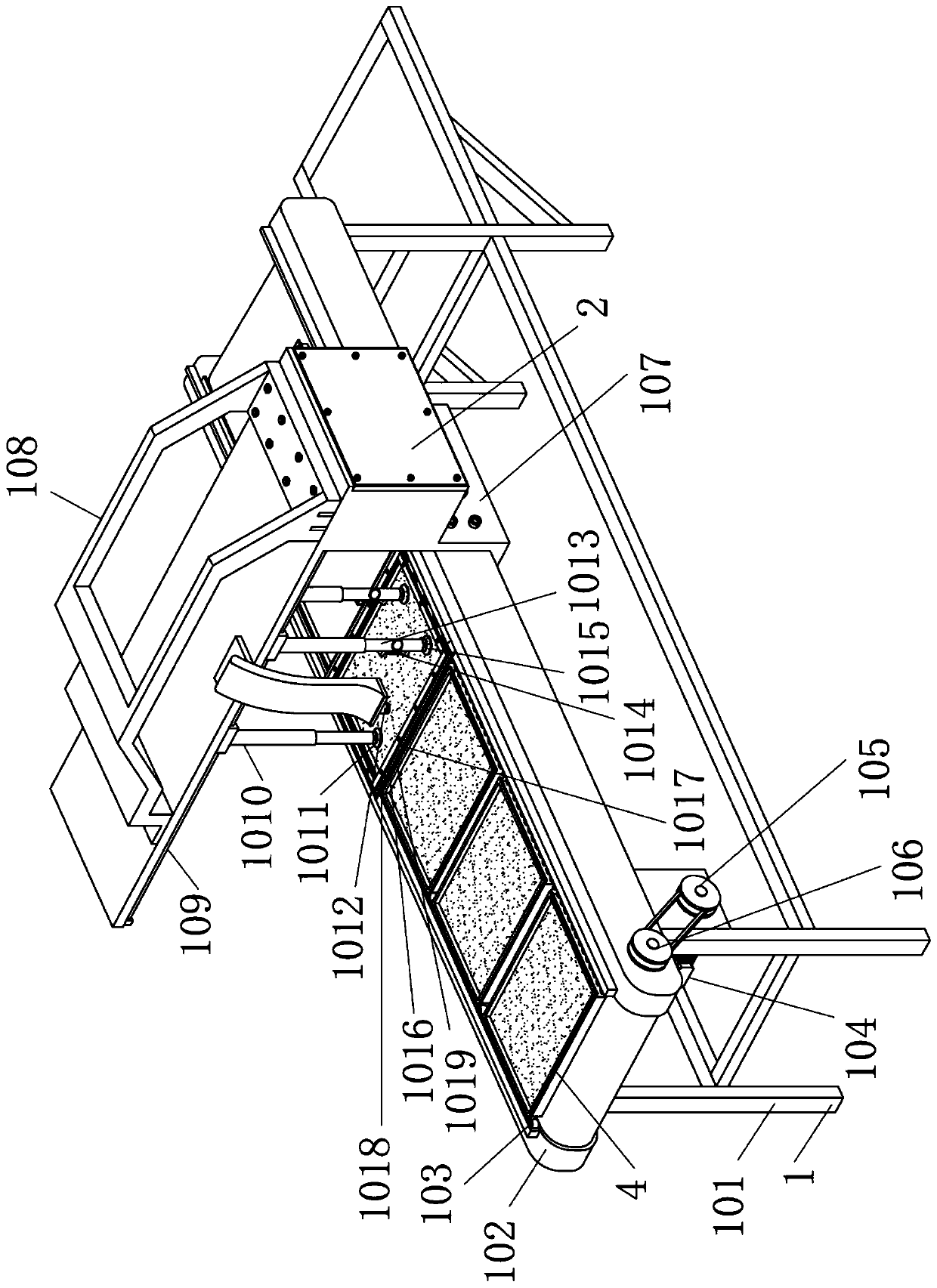

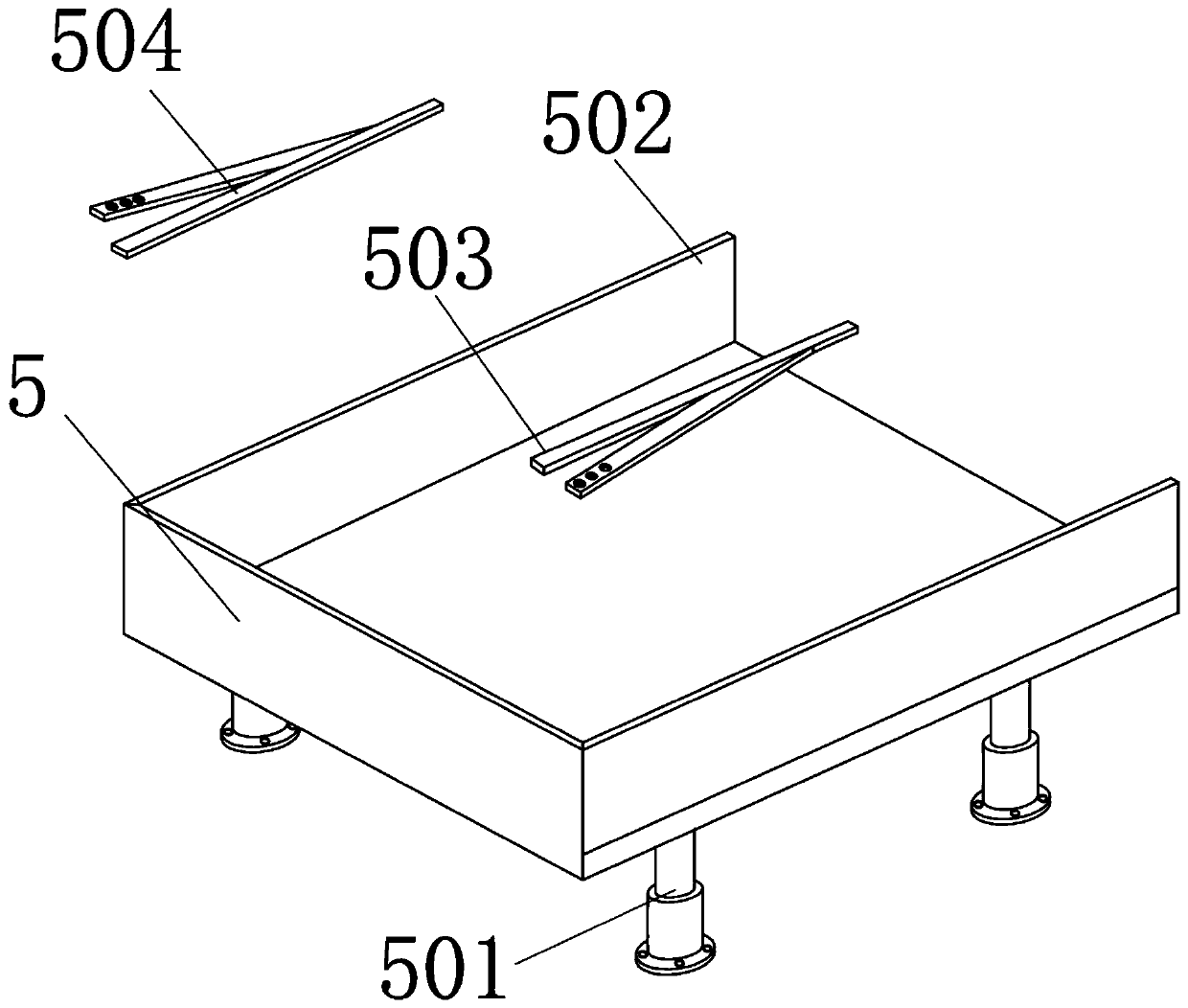

[0030] An automatic demoulding device for prefabricated components, including a vertical demoulding mechanism 1, a side cover 2, a control panel 3, a prefabricated component mold 4, a lower mold mechanism 5 and a repair mechanism 6; A side cover 2 is arranged on the side; a control panel 3 is arranged on the upper left middle of the top of the vertical demoulding mechanism 1; a prefabricated component mold 4 is placed on the top front of the vertical demoulding mechanism 1; There is a lower mold mechanism 5; a repair mechanism 6 is arranged on the left side of the demoulding mechanism 1.

[0031] Working principle: when in use, first place the automatic demoulding device for prefabricated components at the position to be used. It can be transferred to the palletizing equipment on the discharge side of the repair mechanism 6, or it can be replaced manually, and then controlled by the control panel 3, the prefabricated The component mold 4 is placed on the vertical demoulding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com