Construction method for column mold composed of concrete formworks

A technology of concrete formwork and construction method, which is applied in the direction of formwork/formwork/work frame, manufacturing tools, ceramic molding machine, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

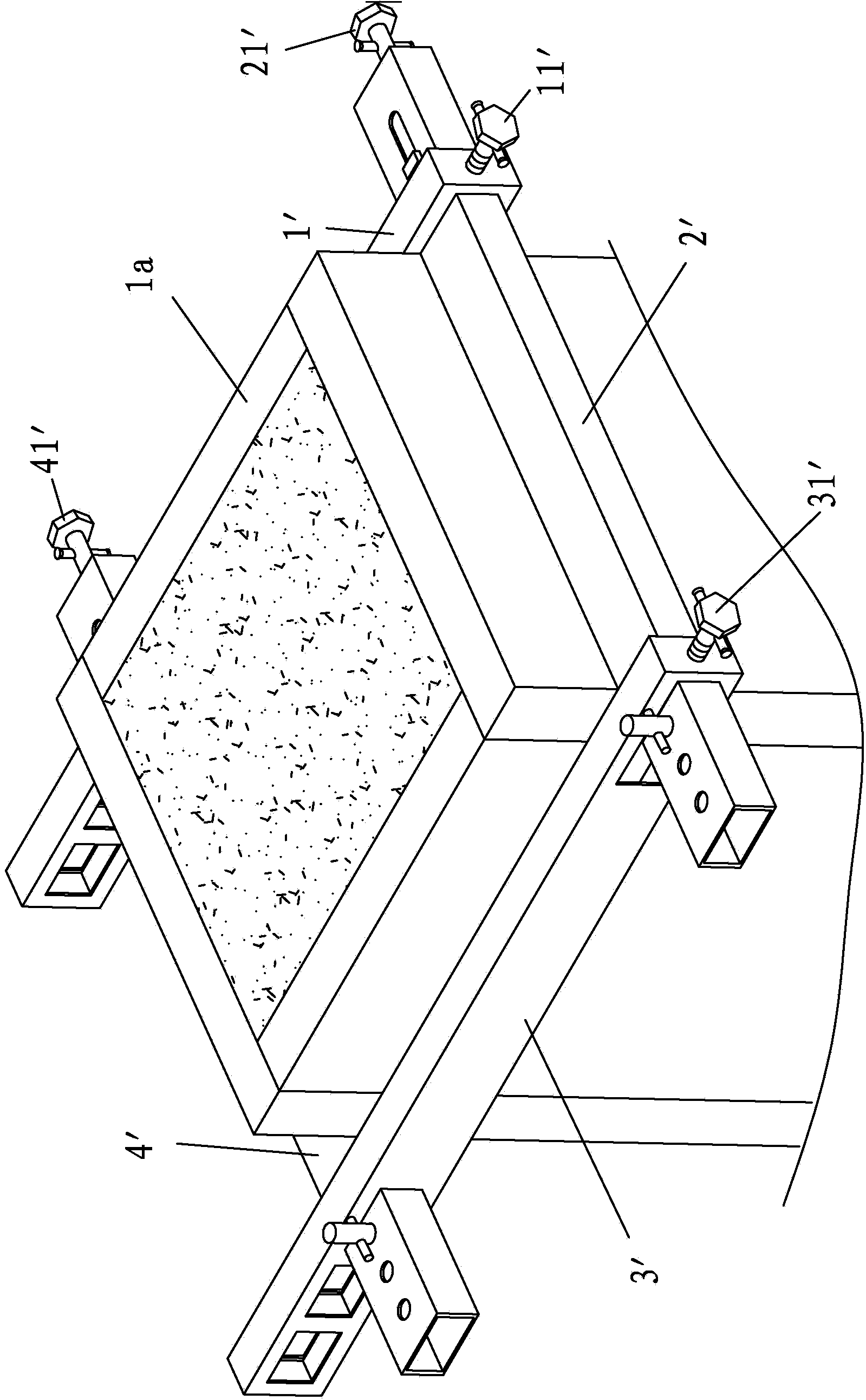

[0051] Such as Figures 2 to 12 Shown, the column formwork construction method that concrete formwork of the present invention is formed, realizes through the following steps.

[0052] 1. Spare parts

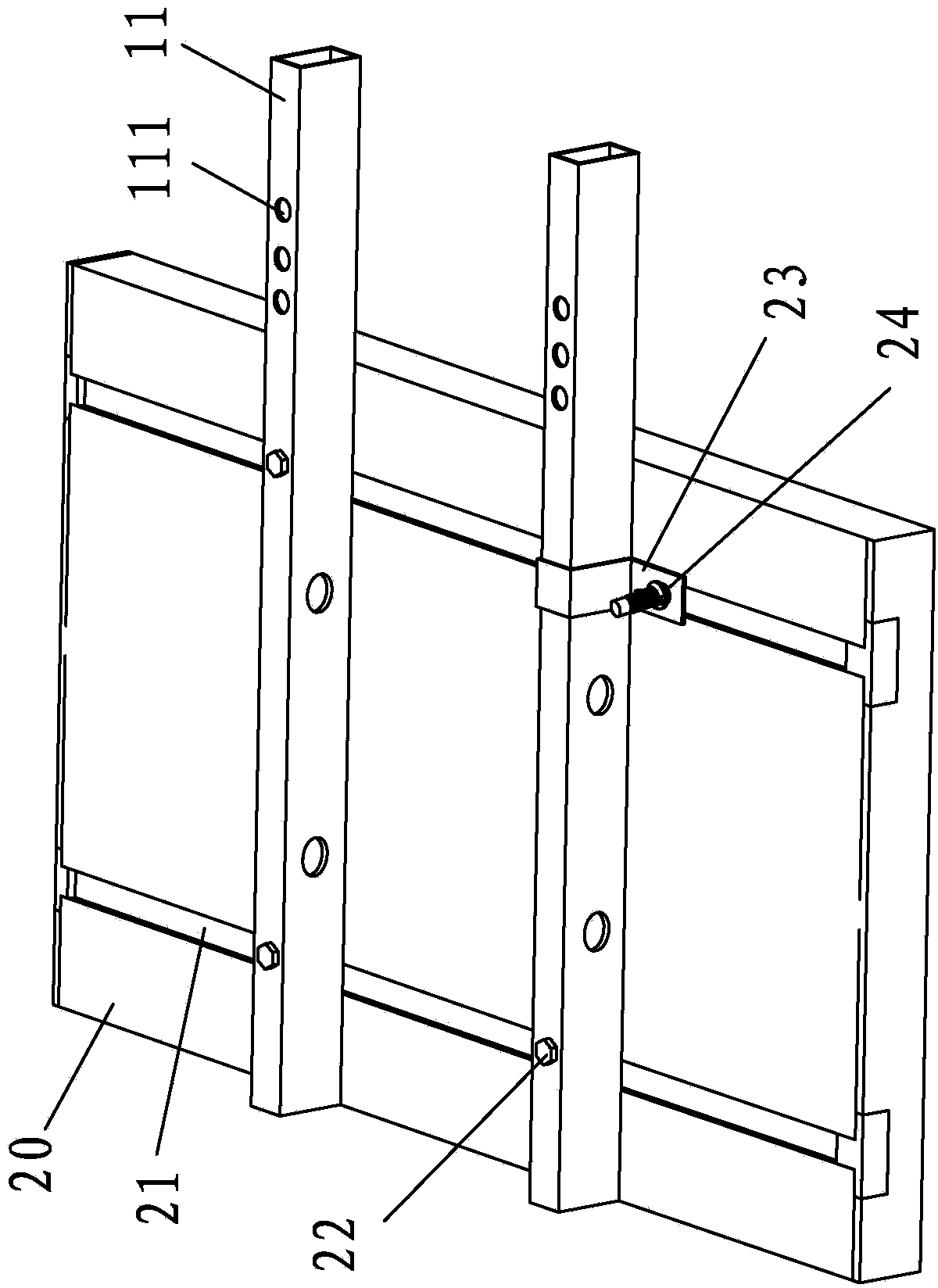

[0053] Main and auxiliary parts are provided: column frame 10 , concrete formwork 20 , caulking part 30 and support part 40 .

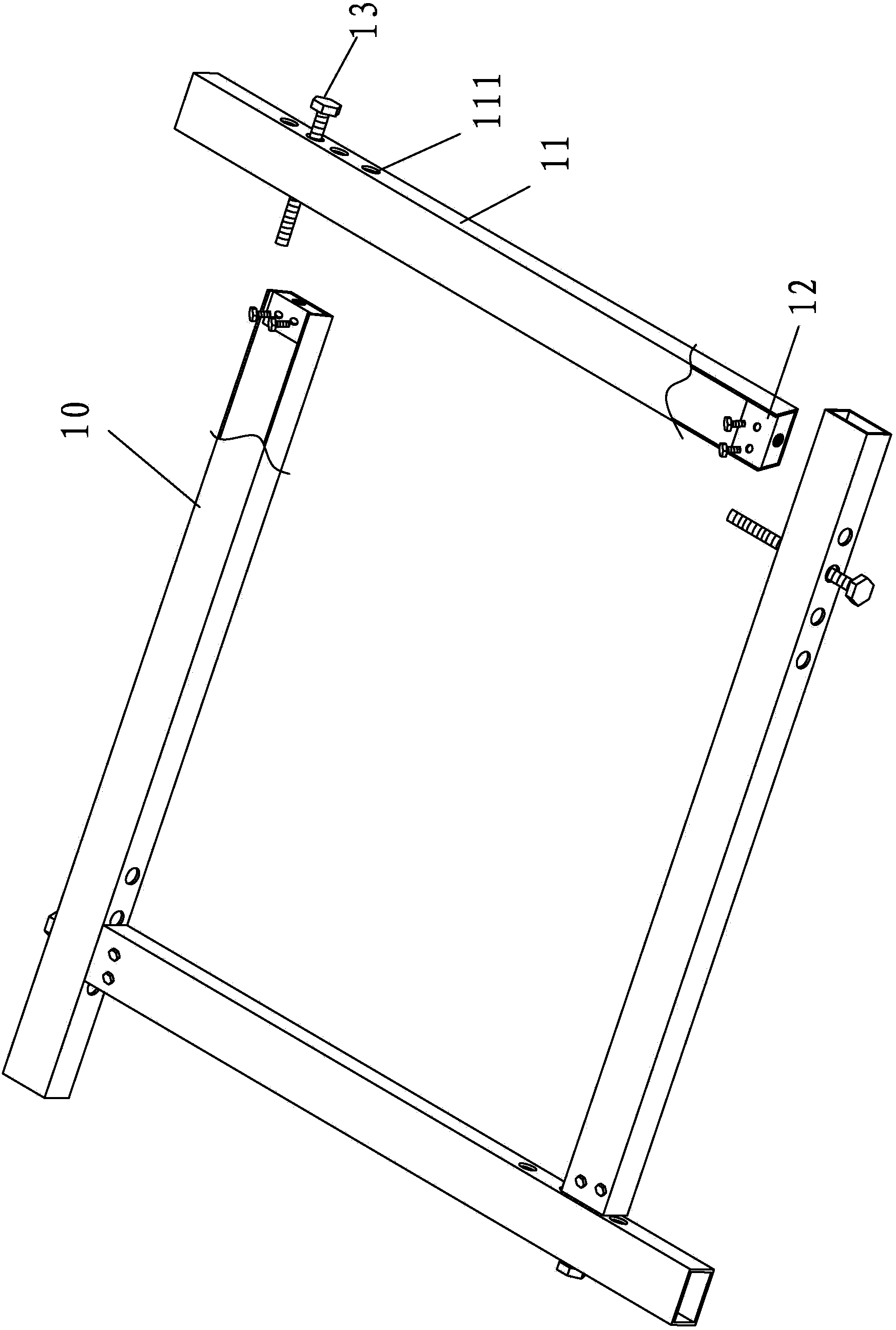

[0054] The column frame 10 can have various shapes, such as square, rectangular, pentagonal, hexagonal and other polygonal shapes. The following takes the square shape as an example for illustration.

[0055] The column frame 10 includes a square tube 11, a tube nut 12 and a tube bolt 13, wherein the tube nut 12 and the tube bolt 13 are conventional nuts and bolts, and this name is adopted for the convenience of distinguishing the nuts and bolts used in other positions below.

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com