Feeding conveyer for machining of large workpiece

A technology for large workpieces and conveyors, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., it can solve the problem that it is difficult to meet the requirements of straightness and stability, metal workpieces are not allowed to be finished, and the speed of workpieces and power rollers Poor problems, to achieve the effect of simple structure, low manufacturing cost, and good straightness of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the intention of the present invention, the intention of the invention will be further described below through the examples, but the intention of the invention is not limited by the examples.

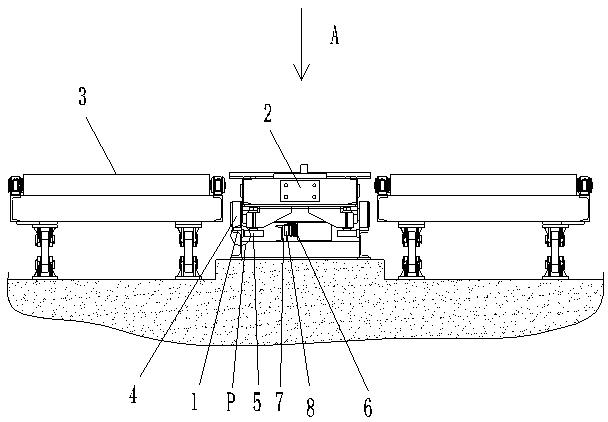

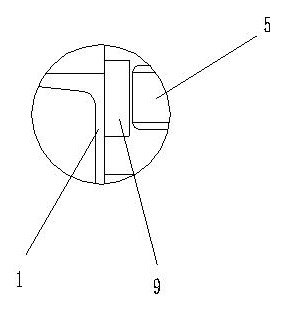

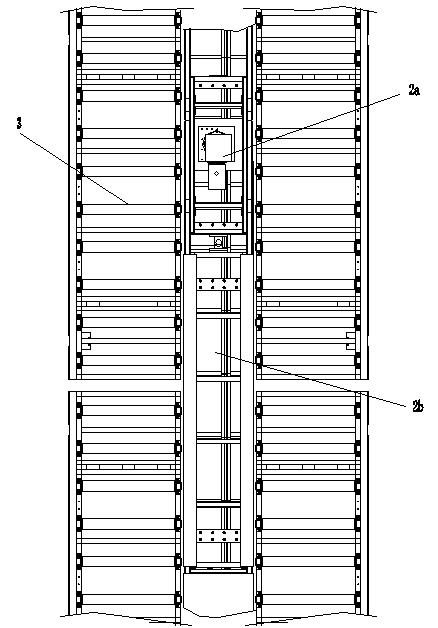

[0023] figure 1 It is a schematic diagram of the overall structure of the large-scale workpiece processing feed conveyor of the present invention; figure 2 for figure 1 Middle P enlarged view; image 3 for figure 1 The A-direction view, the direction indicated by the arrow in the figure is the forward direction of the conveyor; Figure 4 Front view of the driving car.

[0024] As shown in the figure, the feeding conveyor for processing large workpieces of the present invention includes a track 1 and a driving car 2 for carrying and driving the workpiece to move along the track. The driving car 2 is arranged on the track in a manner that can reciprocate along the track 1 superior. The workpiece is conveyed by the driving car movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com