Shaping and cutting module

A module and cutting technology, applied in the field of shaping and cutting modules, can solve the problems of high equipment cost, power consumption or gas source for processing, limited process efficiency, etc., to achieve simple and convenient adjustment and operation, and improve the quality of shaping and cutting , The effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

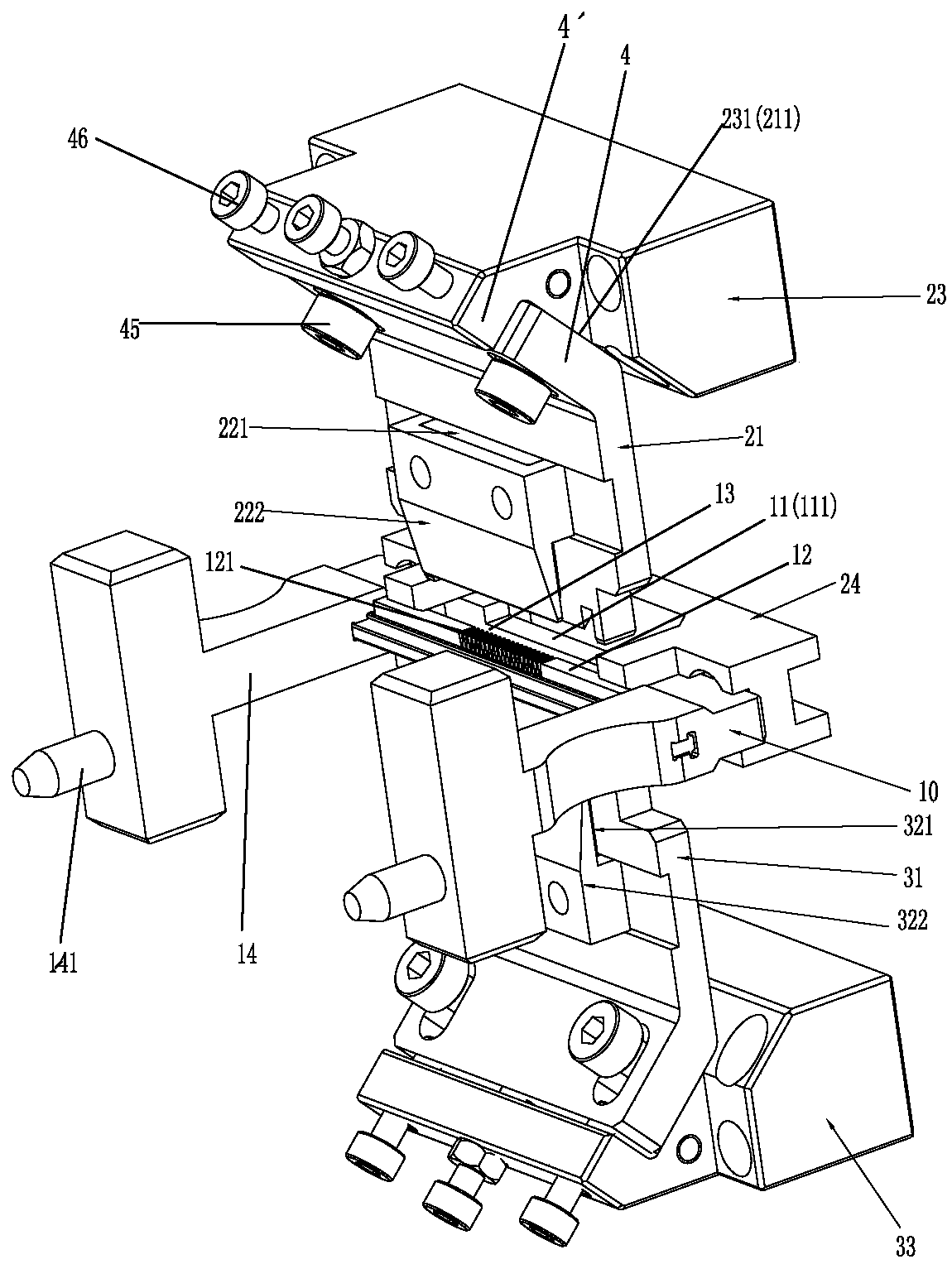

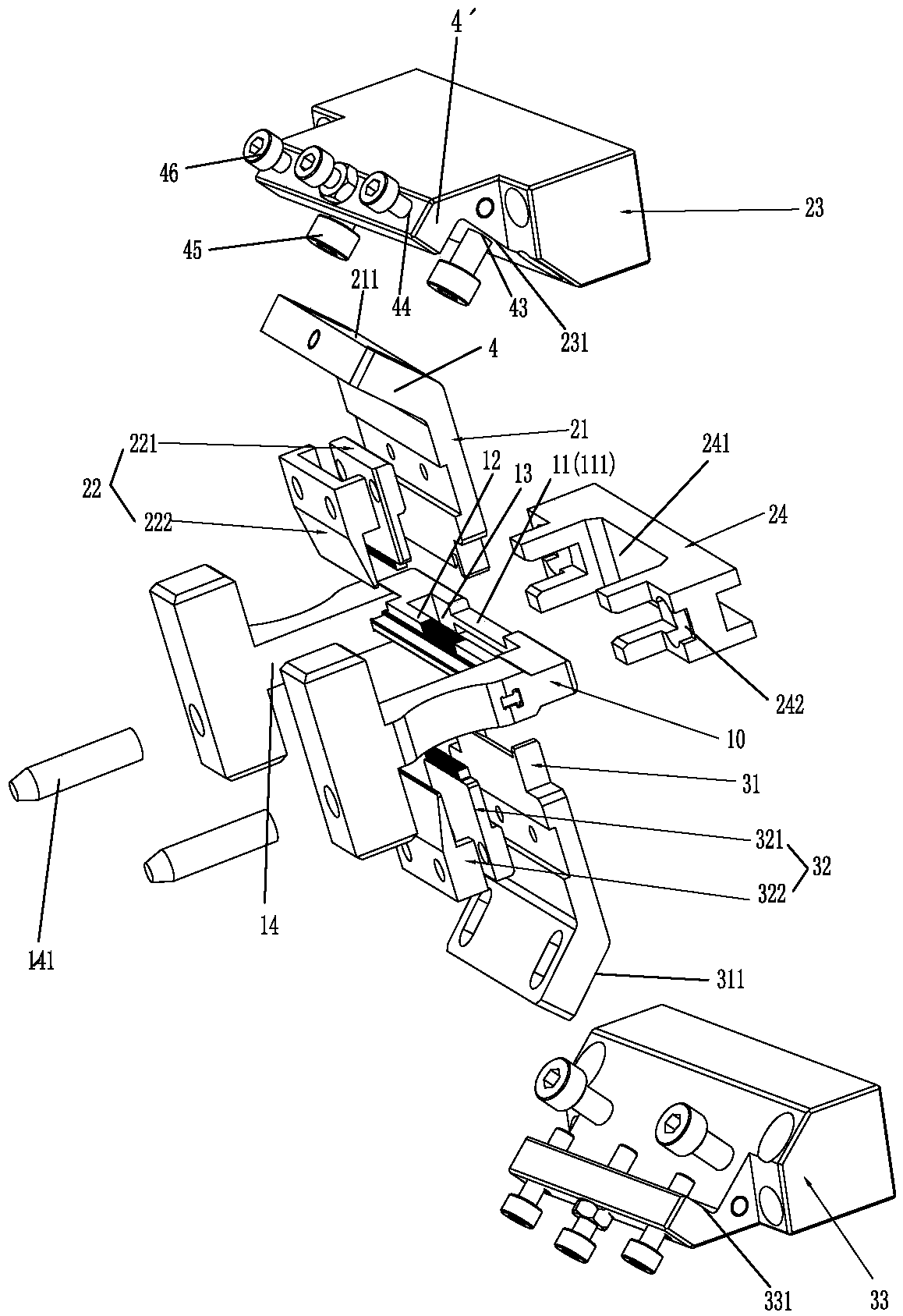

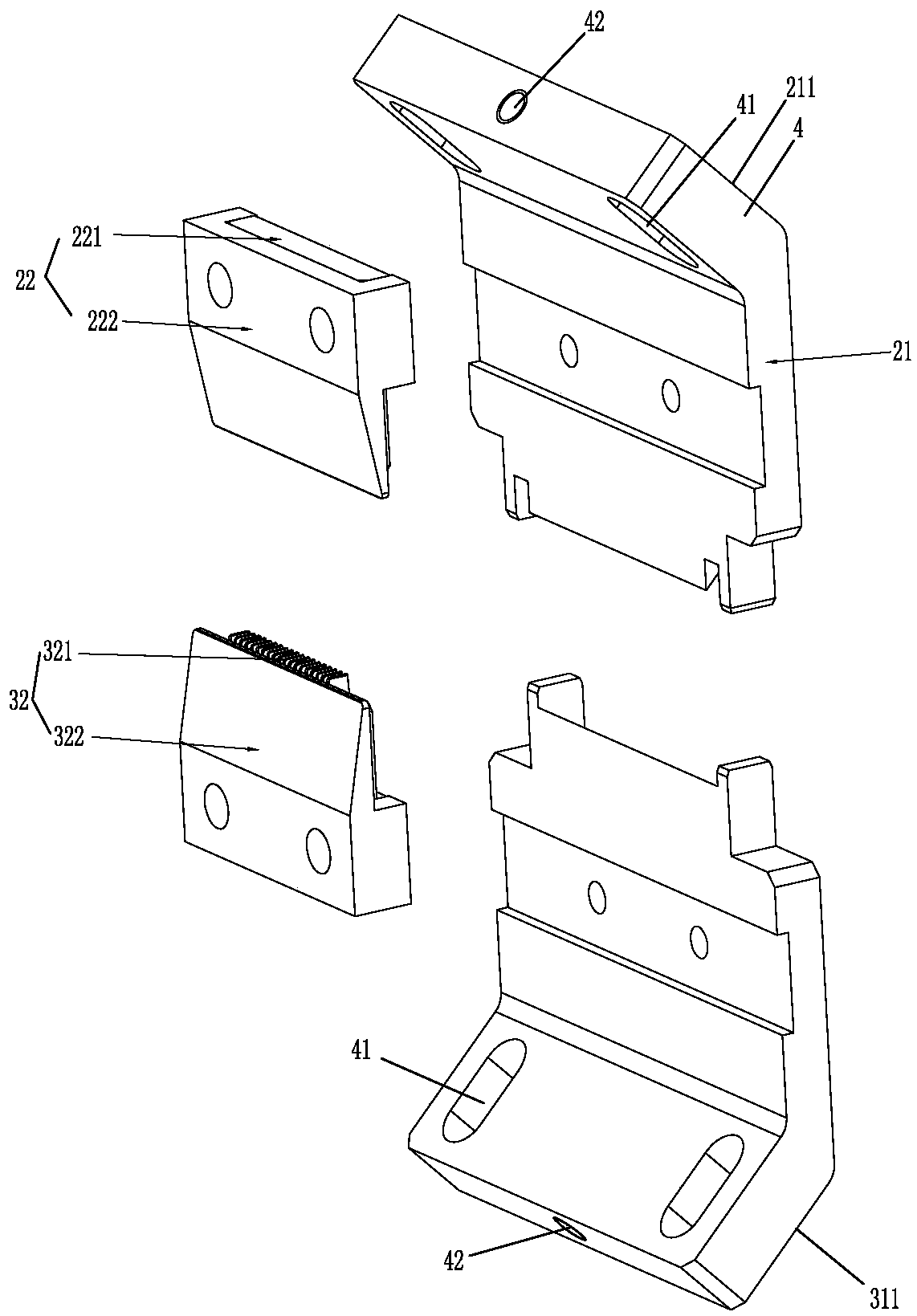

[0067] Please refer to Figure 1 to Figure 14 Shown, it has shown the concrete structure of the embodiment of the present invention; Figures 1 to 3 In , it mainly reflects the local structure of the shaping and cutting module; Figure 4 to Figure 5 It embodies the effect of the cable 6 after the cable is cut and not shaped, and the cable is cut and shaped; Figure 6 to Figure 14 It embodies two operation methods when performing shaping and cutting combined with the setting of the wire clamping and positioning jig.

[0068] First, please refer to Figure 1 to Figure 5 As shown, a plastic cutting module includes an upper plastic cutter assembly, an intermediate line management knife 10, and a lower plastic cutter assembly; both the upper plastic cutter assembly and the lower plastic cutter assembly can be selectively Towards the middle wire management knife 10, close to each other or back away from the middle wire management knife 10; realize synchronous shaping and cutting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com