Cross-beam-type six-dimensional force sensor with overload protection function

A technology of six-dimensional force sensor and overload protection, which is applied in the field of cross-beam six-dimensional force sensor, which can solve the problems such as difficulty in guaranteeing the strength and stiffness of the gap precision sensor, and achieve the effect of high stiffness, improved stiffness and dynamic performance, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

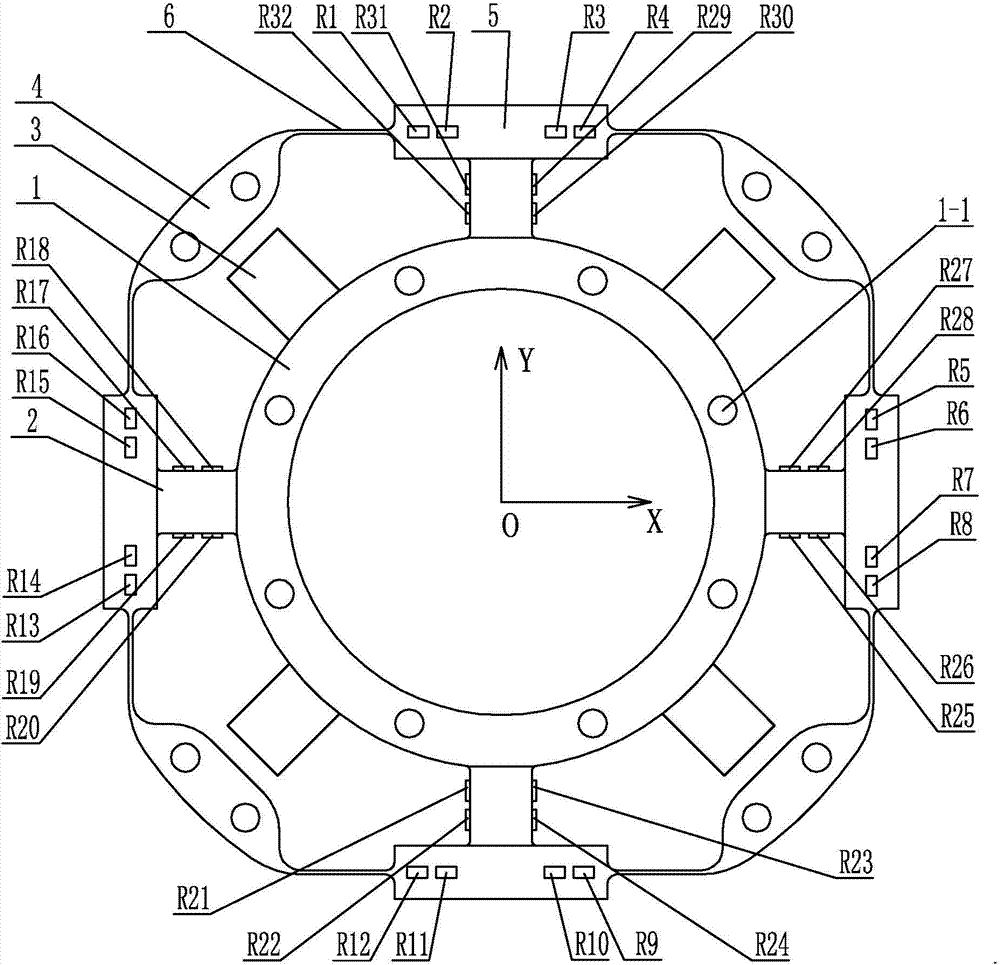

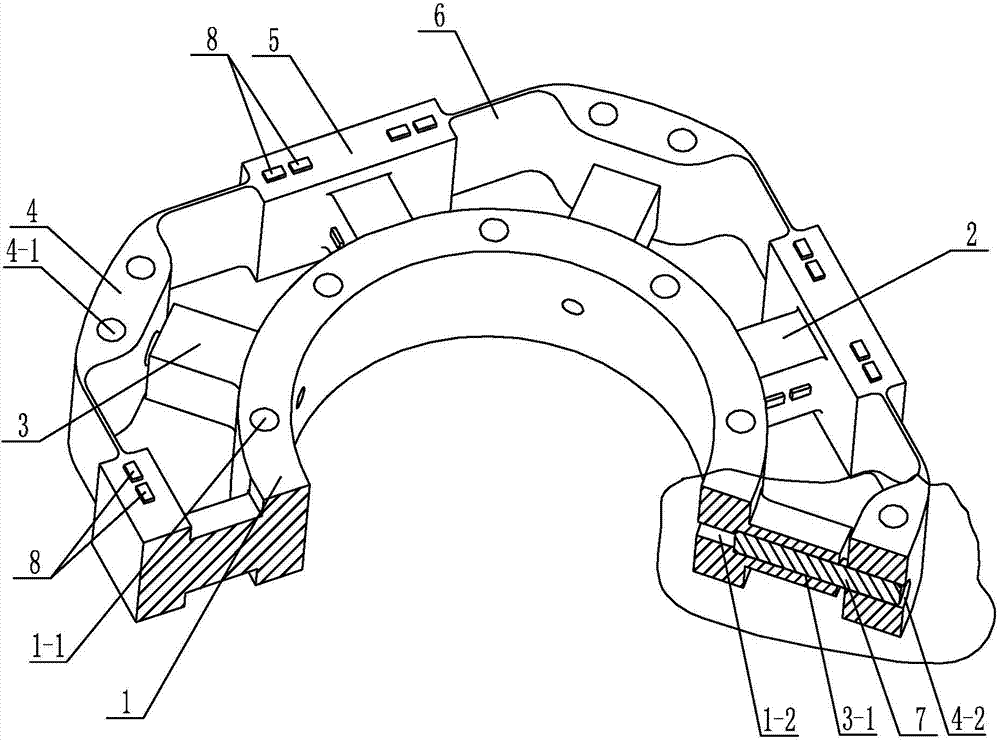

[0022] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes inner ring 1, four inner beams 2, four overload protection beams 3, four outer rings 4, four outer beams 5, four protection pins 7, eight connecting plates 6 and Thirty-two resistance strain gauges 8, four inner beams 2 and four overload protection beams 3 are evenly distributed and staggered along the outer wall of the inner ring 1, four outer beams 5 are arranged on the outside of the four inner beams 2, and four outer beams The beam 5 is arranged in one-to-one correspondence with the four inner beams 2, and the outer beam 5 is fixedly connected to the corresponding inner beam 2. An outer ring 4 is arranged on the outer side of each overload protection beam 3, and an outer ring 4 is arranged between two adjacent outer rings 4. An outer beam 5 is arranged between them, and the two ends of the outer beam 5 are respectively fixedly connected with the outer...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 2 Describe this embodiment, the determination of the inner diameter D of the outer ring process through hole 4-2 of this embodiment: under the rated load of Fx, Fz, Mx and Mz calculated respectively in the finite element analysis software, the protection pin 7 is relatively outer The maximum displacements along the radial direction of the through hole 4-2 of the ring process are respectively S1, S2, S3 and S4, and the minimum displacement is set as S0=min{S1, S2, S3, S4}, and the six-dimensional force sensor is set at The overload multiple under the minimum displacement condition is x, then the sum of the outer diameter D0 of the protection pin 7 and x times the minimum displacement S0 is the inner diameter D of the through hole 4-2 of the outer ring process, that is, D=D0+x*S0 . Fx is the tangential force along the X-axis, Fz is the axial force along the Z-axis, Mx is the bending moment around the X-axis, and Mz is...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 2 To describe this embodiment, the axes of each corresponding inner ring process through hole 1-2, overload protection beam through hole 3-1 and outer ring process through hole 4-2 in this embodiment are on the same line. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com