Flexible nanometer column array with top end coated with precious metal and preparation method and application thereof

A nano-pillar array and precious metal technology, applied in the nano field, can solve the problems of high preparation cost of silicon nano-hole template, affecting the effective excitation of local electromagnetic field, large pore size and hole spacing, etc., achieving low cost, easy operation and good adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

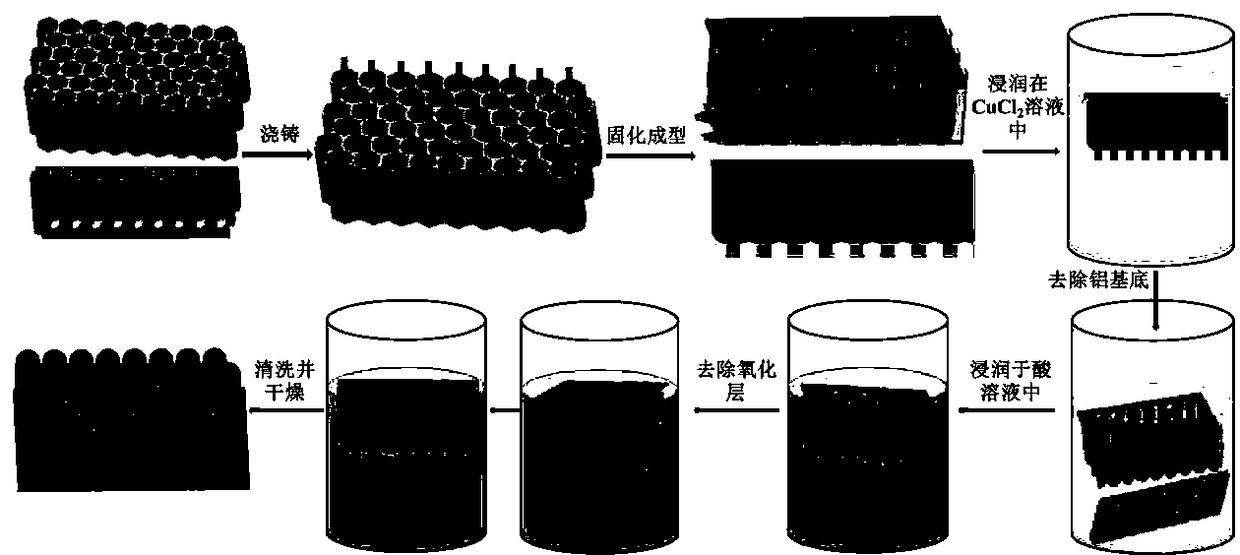

[0037] The concrete steps of preparation are:

[0038] Step 1: Prepare 6 wt% polystyrene toluene solution (PS solution), stir evenly, and let stand for more than 2 h, wherein the molecular weight of polystyrene is 300,000. Place the cleaned aluminum oxide template (2 cm*2 cm) with a pore size of 200 nm in a petri dish with a flat bottom, with the side with holes facing up, titrate 200 ul of PS solution on the front of the template, and place in a fume hood Stand in the middle for 10min.

[0039]In step 2, the template is placed in an airtight chamber, and the toluene solution is quickly volatilized by using an air pump to evaporate the toluene solution, and at the same time, the bottom of the initially cured flexible nano-column array film can be made smoother. Then the template was cured in an electric oven at 60°C for 1 day.

[0040] Step 3, prepare saturated copper chloride solution, then dilute it 10 times, take 100 ml of diluted copper chloride solution, add 20 ml of hy...

Embodiment 2

[0044] The concrete steps of preparation are:

[0045] Step 1: Prepare 6 wt% polystyrene toluene solution (PS solution), stir evenly, and let stand for more than 2 h, wherein the molecular weight of polystyrene is 300,000. Place the cleaned alumina template (2 cm*2 cm) with a pore size of 90 nm in a petri dish with a flat bottom, with the side with holes facing up, titrate 200 ul of PS solution on the front of the template, and place in a fume hood Stand for 15 min.

[0046] In step 2, the template is placed in an airtight chamber, and the toluene solution is quickly volatilized by using an air pump to evaporate the toluene solution, and at the same time, the bottom of the initially cured flexible nano-column array film can be made smoother. Then the template was cured in an electric oven at 60 °C for 2 days.

[0047] Step 3, prepare saturated copper chloride solution, then dilute it 10 times, take 100 ml of diluted copper chloride solution, add 20 ml of hydrochloric acid an...

Embodiment 3

[0051] The concrete steps of preparation are:

[0052] Step 1: Prepare 6 wt% polystyrene toluene solution (PS solution), stir evenly, and let stand for more than 2 h, wherein the molecular weight of polystyrene is 300,000. Place the cleaned alumina template (2 cm*2 cm) with a pore size of 80 nm in a petri dish with a flat bottom, with the side with holes facing up, titrate 200 ul of PS solution on the front of the template, and place in a fume hood Stand in the middle for 25 min.

[0053] In step 2, the template is placed in an airtight chamber, and the toluene solution is quickly volatilized by using an air pump to evaporate the toluene solution, and at the same time, the bottom of the initially cured flexible nano-column array film can be made smoother. Then the template was cured in an electric oven at 60 °C for 2 days.

[0054] Step 3, prepare saturated copper chloride solution, then dilute it 10 times, take 100 ml of diluted copper chloride solution, add 20 ml of hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com