Construction method for earth pressure balance shield construction pressure launching in subway tunnel engineering

A technology of tunnel engineering and earth pressure balance, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of high construction cost, long construction period, and large dependence on auxiliary construction methods, so as to ensure airtightness and reduce construction Construction period and cost, the effect of rapid pressure building tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

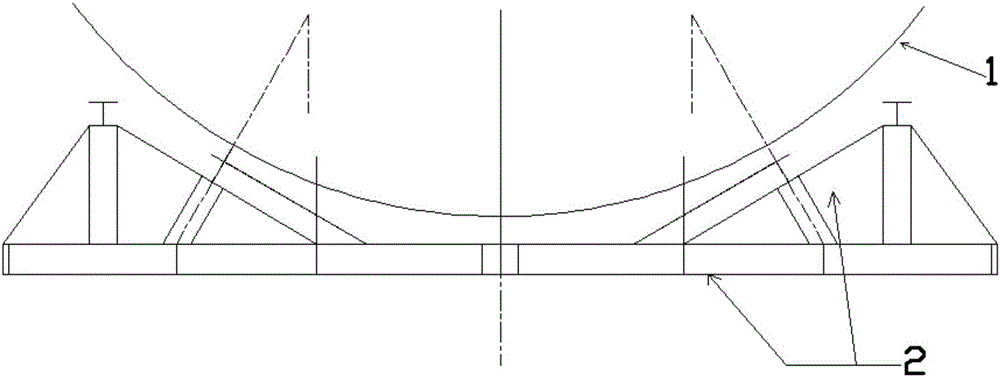

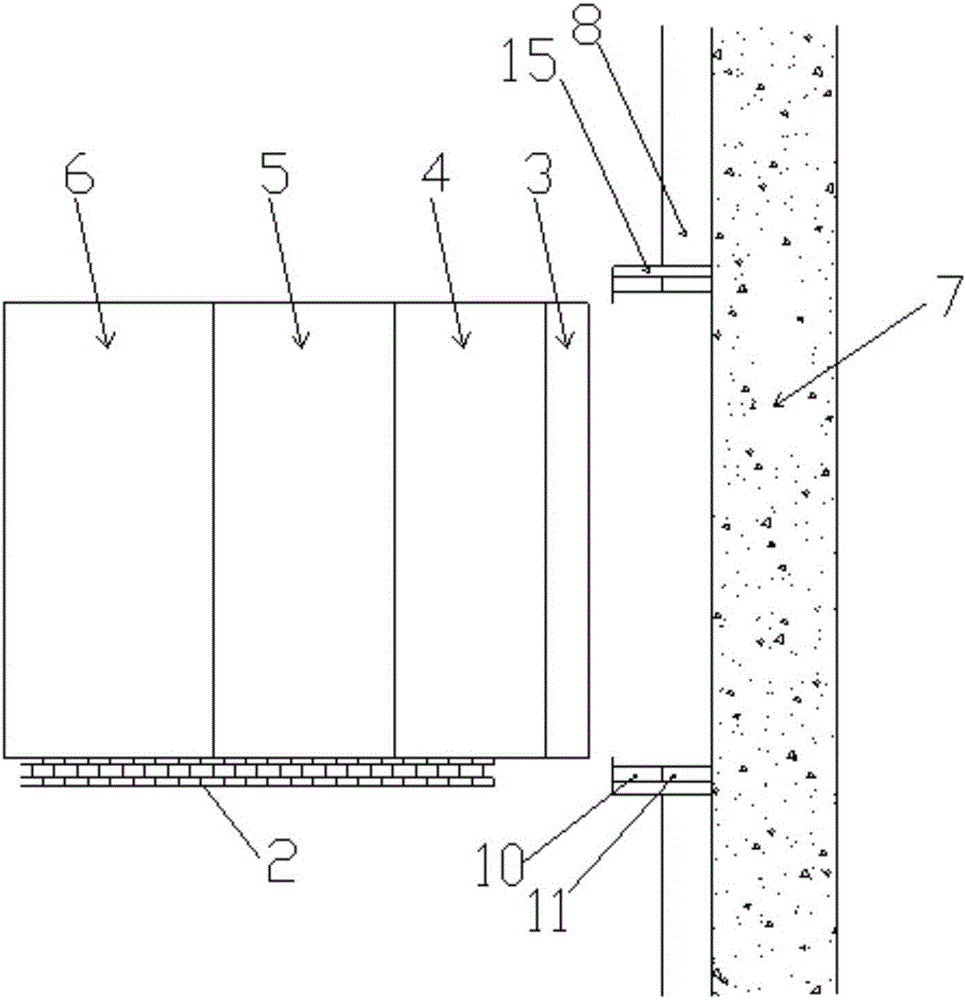

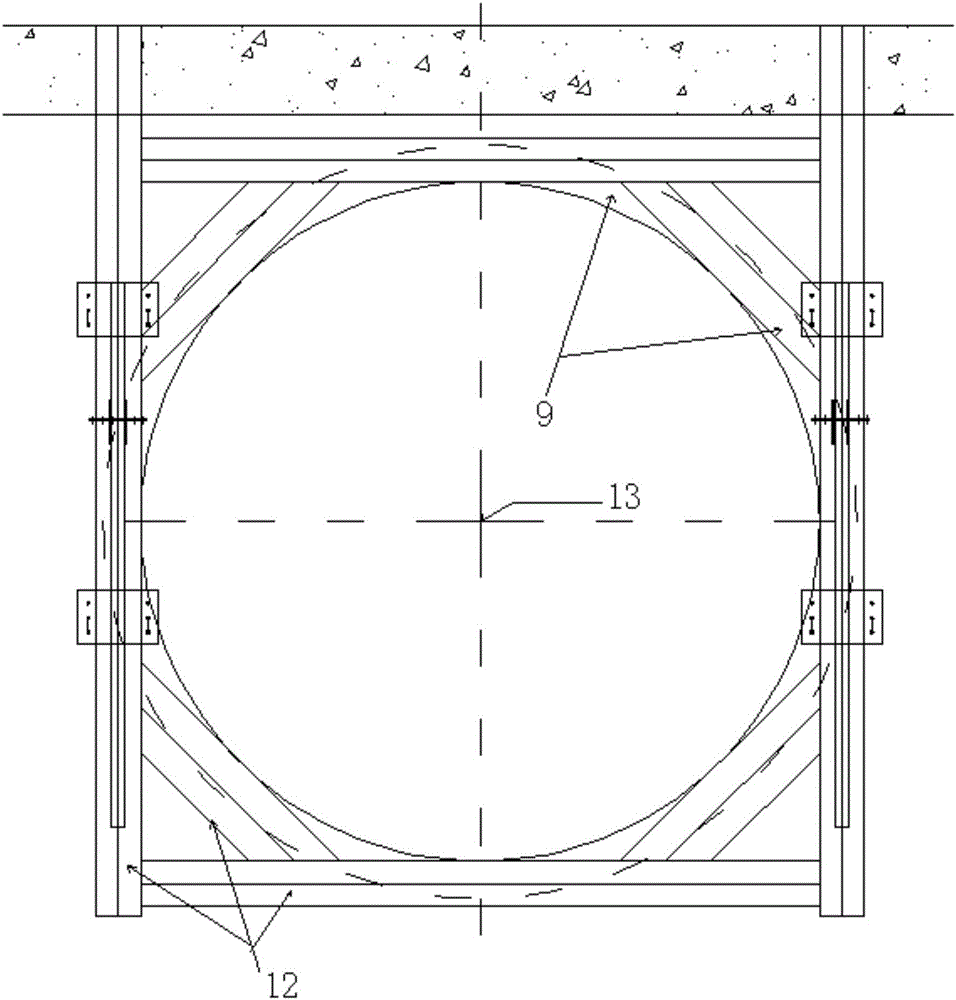

[0052] Such as Figure 1 to Figure 4 As shown, this embodiment provides a construction method for the construction pressure initiation of the earth pressure balance shield in a subway tunnel project, which specifically includes the following steps:

[0053] (A) Carry out pipe shed grouting reinforcement and ground drilling grouting reinforcement for the starting section, the water level before starting is lowered to 1m below the bottom of the tunnel and is stable, and pre-reinforcement is carried out for the crossing structures;

[0054] (B) Determine the spatial position of the starting posture of the shield according to the tunnel design axis, and then deduce the spatial position of the starting platform in reverse. Refer to figure 1 According to the size of the curve section, the tangent starting method is adopted, the installation elevation of the starting bracket is raised by 2cm, and the relative anti-rotation support is welded on the starting platform and the shield mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com