Experimental facility for simulating shield tunnel dynamically boring causing ground loss and surface subsidence

A technology for formation loss and shield tunneling, which is applied in educational appliances, instruments, teaching models, etc., and can solve problems such as difficulty in adapting to tunnel excavation depth and excavation diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

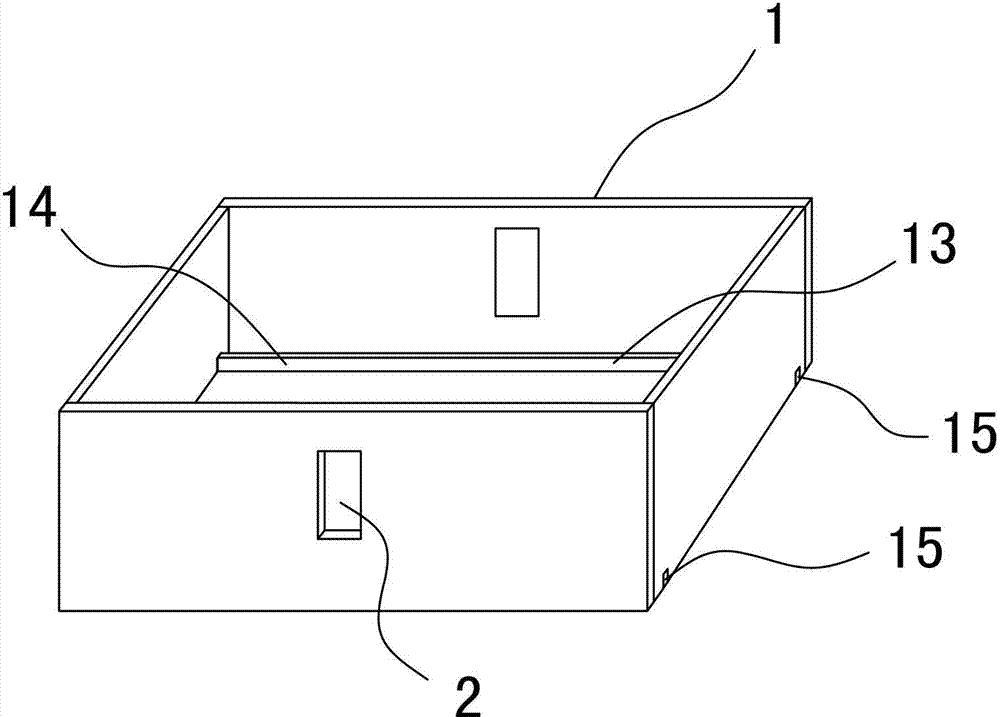

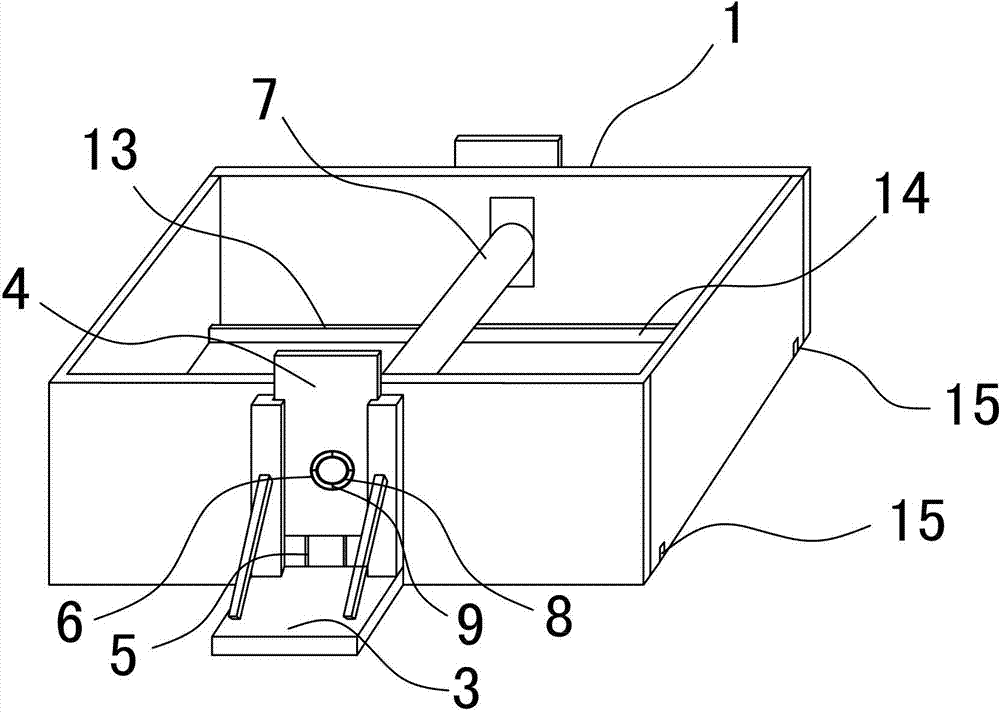

[0024] Example: Shield tunnel dynamic excavation induced formation loss and surface subsidence test device

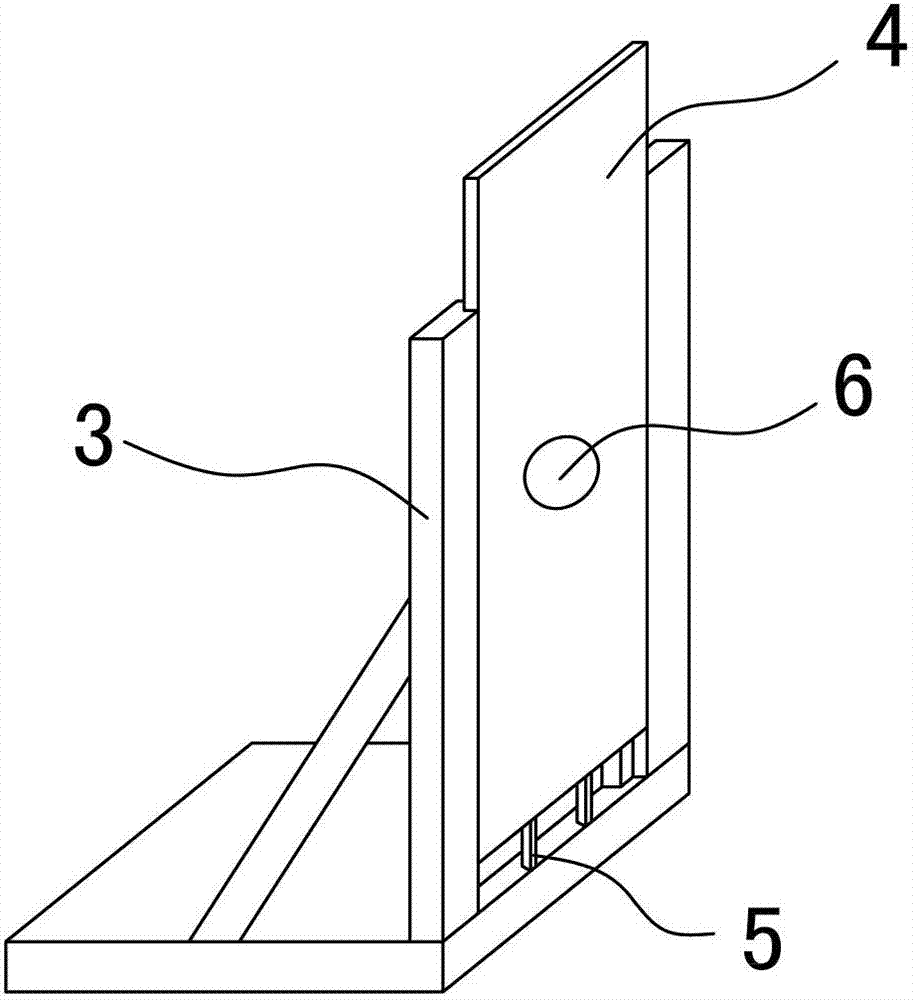

[0025] See attached Figure 1~5 As shown, a model box 1 is included, and the model box 1 is provided with a tunnel simulation mechanism and a lifting adjustment mechanism;

[0026] The model box 1 is a rectangular box with an open top surface. The net size of the rectangular box is 2 meters × 1.5 meters × 1.7 meters (length × width × height). The rectangular box body is composed of four side panels and A bottom panel is spliced together, and the four side panels are respectively the front side panel, the rear side panel, the left side panel and the right side panel. The front side panel, the rear side panel, the left side panel, the right side panel and the bottom panel are all plexiglass The length of the front side panel and the rear side panel is 2 meters, the height is 1.7 meters, and the thickness is 10 mm. The front side panel and the rear side panel are correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com