Shield construction method for clearing obstacles by punching rock stratum section

A construction method and punching technology, applied in the field of obstacles, can solve the problems of difficulty in meeting the site requirements of 120T cranes, the inability to arrange multiple cranes for simultaneous construction, and the failure of normal construction, etc., to achieve small environmental factors, good economic benefits, and construction efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

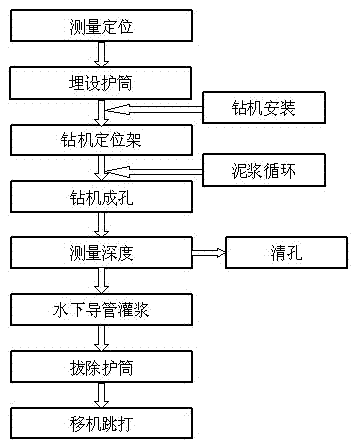

[0027] The construction method of punching and clearing obstacles in the section where the shield encounters rock formations of the present invention:

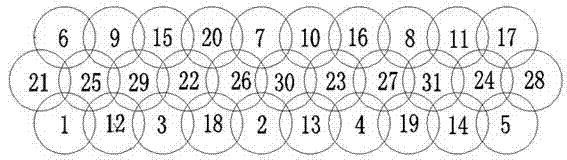

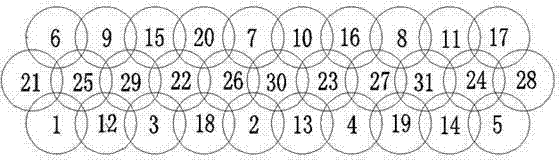

[0028] (1) Determine that the punching and barrier removal construction area is full-section punching construction, the pile holes are overlapped, and the elevation of the pile bottom is lower than the bottom elevation of the shield tunnel, and the later stage is determined based on the detection results and the actual depth of the previous punching construction. Perforated pile width range.

[0029] For example, the scope of tunnel punching and obstacle removal is 41×8m, and the scope of 2# tunnel punching and obstacle removal is 10×8m. The length and width of the clearance can be adjusted on site according to the actual punching construction conditions. If the rock surface is lower than the bottom of the tunnel, the punching and clearance can be stopped, that is, the purpose of achieving the shield machine to excavate mud. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com