Method and device for synchronously grouting shield tunnel pipe sheet

A shield tunnel segment and synchronous grouting technology, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve problems such as poor grouting effects, achieve the effect of preventing floating, preventing water from shield tail, and ensuring early stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

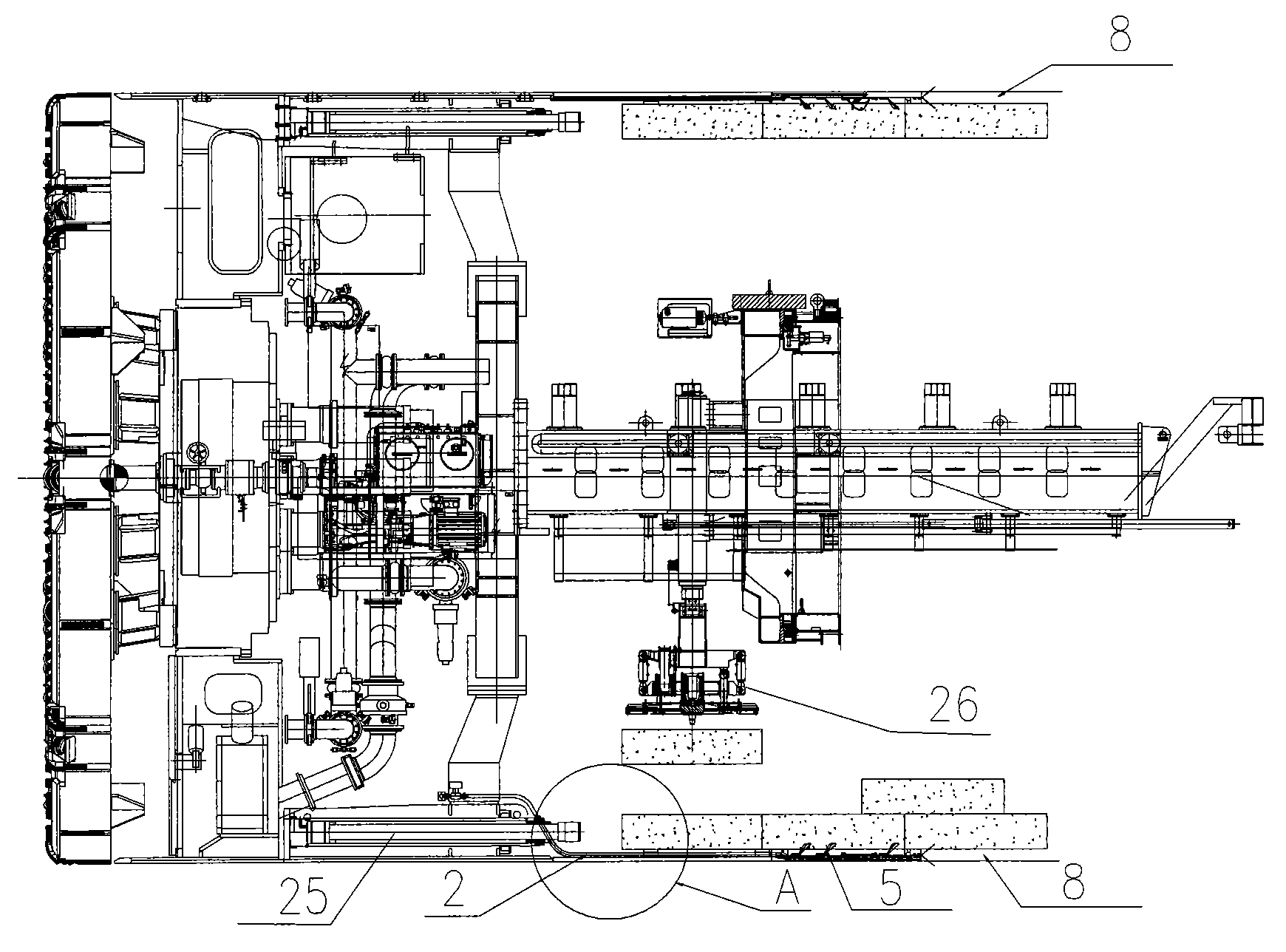

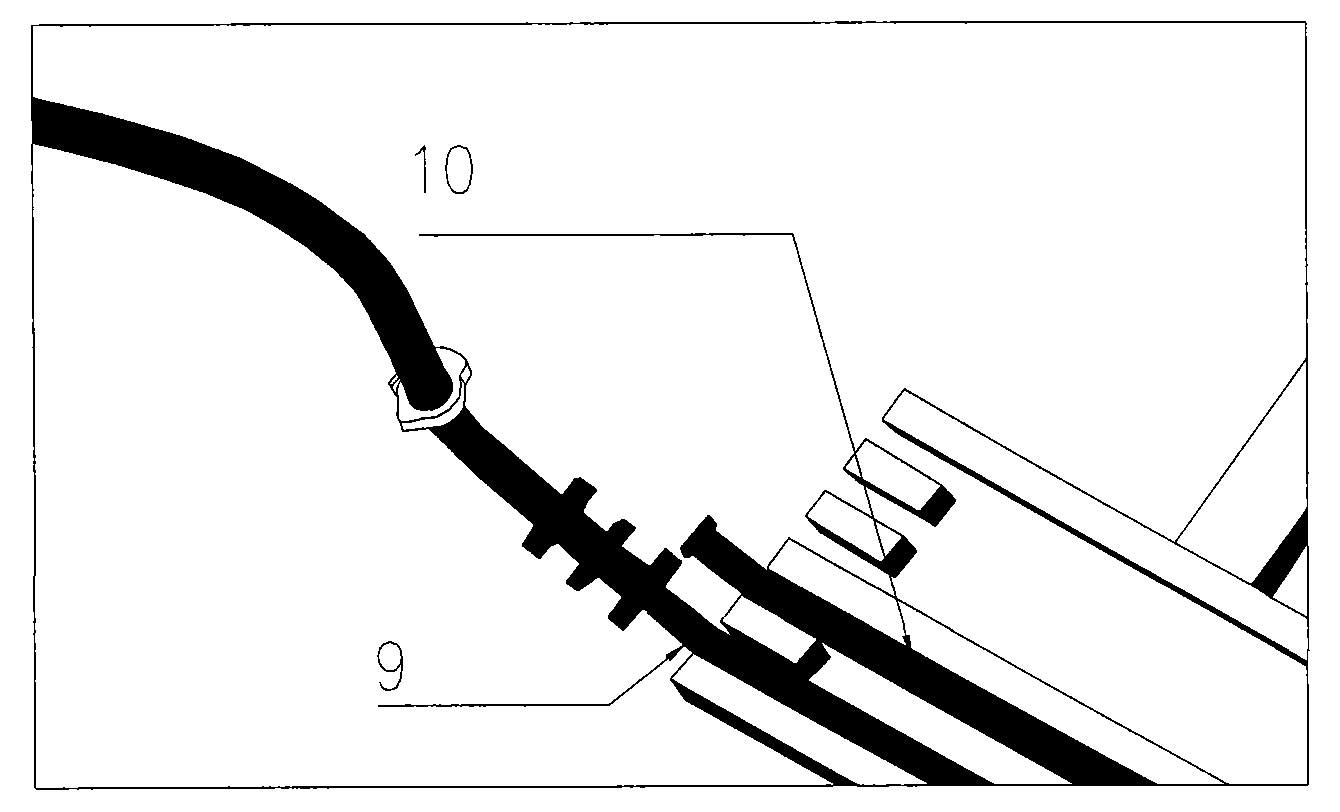

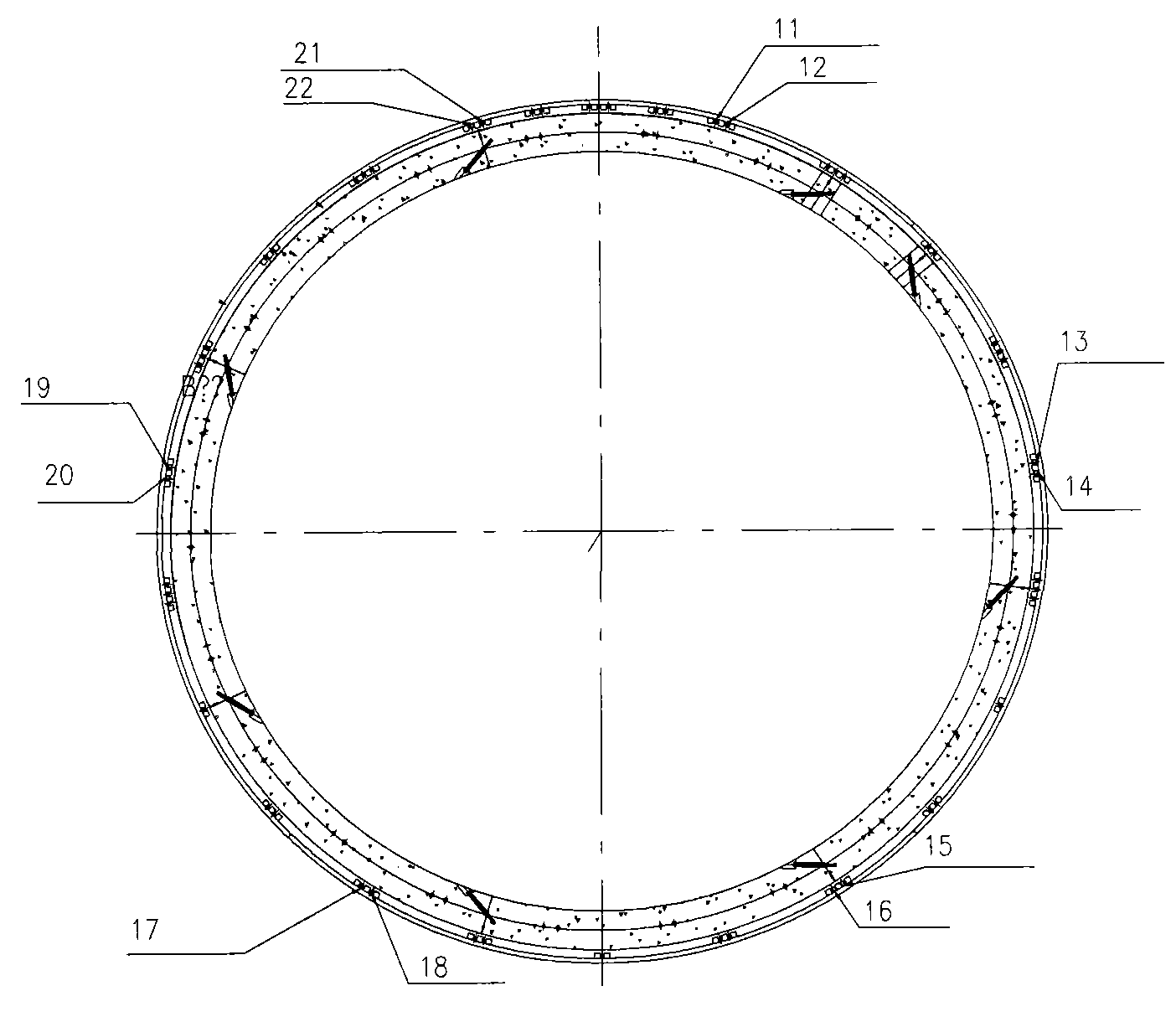

[0024] Such as Figure 1-4 As shown, in the prior art, the shield machine pushes the segment 1 of the lining to advance forward through the forward and backward expansion and contraction of the propulsion cylinder 25, and each segment 1 is installed into a lining ring through the segment installation machine 26. During the excavation of the machine, the segment 1 is gradually exposed from the shield shell 3, and the shield tail brush 5 is provided at the rear of the shield tail gap 4, and there is a large gap between the segment 1 and the formation outside the shield shell 3 , it is necessary to inject grout into the gap, which is the grout filling area 8, to prevent formation deformation, improve the impermeability and appearance quality of the tunnel, ensure the early stability of the segment lining, and provide support for lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com